A Case Study Addendum: How BYD Became A Leader In EV Battery Manufacturing

Table of Contents

BYD's Vertical Integration Strategy: A Key to Success

BYD's dominance in the EV battery market is significantly attributed to its vertically integrated business model. This strategy encompasses control over the entire electric vehicle battery supply chain, from raw material sourcing to cell production and pack assembly. This approach offers several key competitive advantages in the electric vehicle battery industry:

-

Reduced Reliance on External Suppliers: BYD minimizes disruptions and cost fluctuations associated with relying on external suppliers for crucial components. This control ensures consistent supply and protects against price volatility in the raw materials market, a critical factor influencing lithium-ion battery production costs.

-

Enhanced Efficiency in Battery Production: Vertical integration streamlines the manufacturing process, fostering faster innovation and optimization. The ability to coordinate each stage of production allows for immediate adjustments and improvements, enhancing overall efficiency and reducing lead times in battery manufacturing.

-

Stringent Quality Control in the Supply Chain: BYD's control over every stage of the supply chain allows for tighter quality control, ensuring consistent high standards across its electric vehicle battery products. This minimizes defects and ensures the reliability of its batteries, a critical factor for building trust with consumers and automotive manufacturers.

-

Proprietary Technology Development: This integrated approach enables BYD to foster the development of proprietary technologies, most notably the innovative Blade Battery. This unique design offers substantial advantages over traditional lithium-ion batteries, further solidifying BYD's position in the industry.

Technological Innovation: Driving BYD's Competitive Edge

BYD's commitment to research and development (R&D) is a cornerstone of its success. This commitment is clearly demonstrated through its groundbreaking Blade Battery technology. This technology represents a significant advancement in lithium-ion battery technology, offering several key advantages:

-

Superior Energy Density of Blade Battery: The Blade Battery boasts a high energy density, allowing for increased range in electric vehicles without compromising on space efficiency. This is a critical factor in the EV market, where maximizing range is a key selling point.

-

Enhanced Safety Features of Blade Battery: The unique design of the Blade Battery significantly enhances its safety profile compared to traditional cylindrical or prismatic cells. This improved safety minimizes the risk of thermal runaway and enhances overall vehicle safety.

-

Advancements in LFP Battery Chemistry: BYD has made significant strides in lithium iron phosphate (LFP) battery chemistry. LFP batteries offer advantages in terms of safety, cost-effectiveness, and environmental friendliness due to the abundance and sustainability of their raw materials. The environmental benefits of LFP batteries are a strong selling point in an increasingly environmentally conscious market.

-

Continuous Investment in Next-Generation Battery Technologies: BYD continuously invests in research and development, exploring next-generation battery technologies to maintain its competitive edge in the ever-evolving electric vehicle battery market.

Strategic Partnerships and Market Expansion: Fueling Global Growth

BYD's strategic partnerships and market expansion have played a pivotal role in its global success. These collaborations have opened doors to new technologies, resources, and markets, accelerating its growth trajectory.

-

Key Partnerships & Collaborations: BYD has formed strategic alliances with key players in the automotive industry and beyond, providing access to valuable resources, expertise, and distribution networks. This allows for faster market penetration and strengthens its position as a key player in the global EV battery industry.

-

Market Penetration Strategy: BYD has implemented a targeted market penetration strategy focusing on key regions with high EV adoption rates. This calculated approach ensures efficient allocation of resources and maximizes market impact.

-

Impact on Overall Growth: These strategic partnerships and market expansion efforts have been crucial in boosting BYD's overall growth, establishing a strong global presence, and solidifying its position as a leading EV battery manufacturer.

Sustainability and Environmental Responsibility: A Core Value Proposition

BYD's commitment to sustainability is integral to its business model. The company actively works to minimize the environmental impact of its battery manufacturing operations, reinforcing its position as a responsible corporate citizen.

-

Renewable Energy in Production: BYD utilizes renewable energy sources in its production facilities, reducing its reliance on fossil fuels and minimizing its carbon footprint. This commitment aligns with global sustainability efforts and enhances its brand image.

-

Emission Reduction and Waste Management: BYD actively implements initiatives to reduce carbon emissions and waste throughout its manufacturing processes, promoting environmentally friendly practices. This reflects a long-term commitment to responsible manufacturing.

-

Environmental Benefits of LFP Battery Technology: The use of LFP battery technology contributes to reduced environmental impact compared to other battery chemistries. LFP batteries require less energy to produce and have a smaller carbon footprint, making them a more sustainable choice.

Conclusion

BYD's rise to the top of the EV battery manufacturing sector is a testament to its strategic vision and operational excellence. Its vertically integrated strategy, technological innovation exemplified by the Blade Battery, strategic partnerships, and commitment to sustainability have all contributed to its remarkable success. BYD’s impact on the global transition to electric vehicles is undeniable. The company's success story provides valuable insights for companies aspiring to compete in this dynamic and rapidly growing market. Learn more about the latest advancements in EV battery technology and explore how BYD's integrated approach can inform your own strategies in EV battery manufacturing.

Featured Posts

-

Your Weekly Dose Of Efl Highlights Action And Analysis

May 13, 2025

Your Weekly Dose Of Efl Highlights Action And Analysis

May 13, 2025 -

Dodgers Vs Cubs Game Prediction Analyzing Las Unbeaten Home Streak

May 13, 2025

Dodgers Vs Cubs Game Prediction Analyzing Las Unbeaten Home Streak

May 13, 2025 -

Alarm An Braunschweiger Schule Details Zum Vorfall Und Massnahmen

May 13, 2025

Alarm An Braunschweiger Schule Details Zum Vorfall Und Massnahmen

May 13, 2025 -

Landman Season 2 Whos Back And Whos Not

May 13, 2025

Landman Season 2 Whos Back And Whos Not

May 13, 2025 -

Effective Cross Border Crime Fighting Mechanisms And Challenges

May 13, 2025

Effective Cross Border Crime Fighting Mechanisms And Challenges

May 13, 2025

Latest Posts

-

Schiphol Road And Ferry Traffic Easter And Spring Holiday Peak Days Predicted

May 13, 2025

Schiphol Road And Ferry Traffic Easter And Spring Holiday Peak Days Predicted

May 13, 2025 -

Plan Ahead Peak Travel On Schiphol Roads And Ferries This Easter Weekend

May 13, 2025

Plan Ahead Peak Travel On Schiphol Roads And Ferries This Easter Weekend

May 13, 2025 -

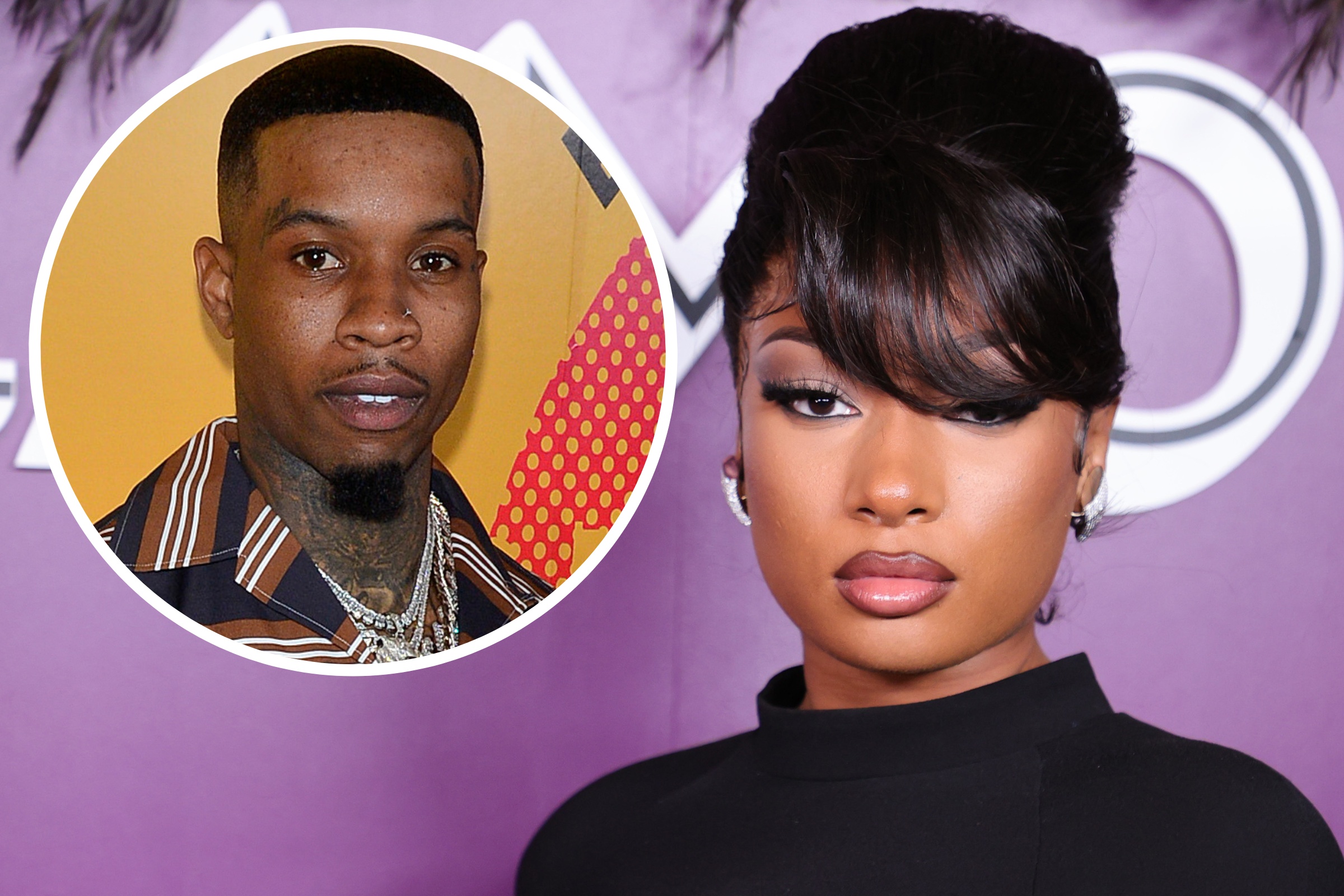

Hip Hop Reacts Tory Lanez And 50 Cent On Megan Thee Stallions Guilty Verdict Prediction

May 13, 2025

Hip Hop Reacts Tory Lanez And 50 Cent On Megan Thee Stallions Guilty Verdict Prediction

May 13, 2025 -

50 Cent And Tory Lanez Weigh In On Predicted Megan Thee Stallion Guilty Verdict

May 13, 2025

50 Cent And Tory Lanez Weigh In On Predicted Megan Thee Stallion Guilty Verdict

May 13, 2025 -

Megan Thee Stallion Case Tory Lanez And 50 Cents Reactions To The Verdict Prediction

May 13, 2025

Megan Thee Stallion Case Tory Lanez And 50 Cents Reactions To The Verdict Prediction

May 13, 2025