All-American Production: A Realistic Assessment Of The Hurdles

Table of Contents

The High Cost of Domestic Manufacturing

The allure of all-American production is undeniable, but the reality is that domestic manufacturing often comes with a substantially higher price tag. Several key factors contribute to this increased cost.

Labor Costs

American wages are significantly higher than in many other countries, dramatically impacting the overall cost of production.

- Comparison: The average hourly wage in the US manufacturing sector is substantially higher than in countries like China, Mexico, and Vietnam. These differences can be several times greater, depending on the skill level required.

- Benefits and Healthcare: American workers also enjoy more comprehensive benefits packages, including health insurance, paid time off, and retirement plans, which add considerably to labor costs.

- Automation's Role: While automation can help mitigate some of these high labor costs, the initial investment is substantial, requiring careful planning and financial resources. Furthermore, not all manufacturing processes are easily automated.

Raw Material Sourcing

Securing domestically sourced raw materials presents another significant challenge, often leading to higher costs and increased supply chain vulnerabilities.

- Import Reliance: Many US manufacturers rely heavily on imported raw materials, creating exposure to global price fluctuations, geopolitical instability, and potential supply chain disruptions.

- Tariffs and Trade Wars: Trade wars and tariffs can further inflate the cost of imported raw materials, making domestic sourcing even more critical but potentially more expensive in the short term.

- Reshoring Raw Material Production: Reshoring the production of raw materials, while potentially beneficial in the long run, requires substantial investment and may not be feasible for all materials. It also faces the same challenges as discussed above regarding labor and infrastructure.

Infrastructure and Logistics

Outdated infrastructure and persistent transportation bottlenecks can significantly increase production costs and lead to frustrating delays.

- Infrastructure Deficiencies: The state of US roads, railways, and ports is a well-documented concern. Aging infrastructure leads to increased transportation times and higher fuel consumption.

- Transportation Costs: Long transportation distances across the vast US landscape, combined with fluctuating fuel prices, significantly contribute to overall logistics costs.

- Infrastructure Investment: Investing in upgrading and modernizing the nation's infrastructure is crucial for reducing transportation costs and improving the efficiency of all-American production.

Competition from Global Manufacturers

Competing with established global manufacturers presents another major obstacle to achieving widespread all-American production.

Price Competitiveness

Lower production costs in many countries give foreign manufacturers a significant price advantage, making it difficult for US businesses to compete solely on price.

- Industry Examples: Industries like textiles, apparel, and certain electronics sectors are particularly vulnerable to this price competition.

- Value-Added Manufacturing: To compete, US manufacturers often need to focus on higher value-added manufacturing, specializing in products with advanced features, superior quality, or unique design elements that command premium prices.

- Niche Markets: Another strategy involves focusing on niche markets with less intense global competition. This approach allows businesses to target customers willing to pay a premium for specialized products.

Global Supply Chains

Existing global supply chains are deeply entrenched, creating a significant barrier to a complete shift to all-American production.

- Supply Chain Re-engineering: Re-engineering existing supply chains to rely exclusively on domestic sources is a complex and costly undertaking.

- Transitional Disruptions: The transition to all-American production can lead to temporary disruptions, impacting production schedules and potentially harming customer relationships.

- Strategic Partnerships: Collaborating with other domestic manufacturers through strategic partnerships can help businesses build stronger, more resilient, all-American supply chains.

Skilled Labor Shortages

A persistent shortage of skilled workers in the manufacturing sector presents a significant impediment to expanding domestic production.

The Skills Gap

The skills gap is a major challenge, requiring targeted efforts to train and develop a skilled workforce capable of meeting the demands of modern manufacturing.

- Vocational Training & Apprenticeships: Investing in robust vocational training programs and apprenticeships is crucial to develop a pipeline of skilled workers.

- Educational Institution's Role: Educational institutions need to adapt their curricula to reflect the evolving needs of the manufacturing industry.

- Upskilling and Reskilling Initiatives: Programs focused on upskilling and reskilling existing workers to meet the demands of advanced manufacturing technologies are also essential.

Attracting and Retaining Talent

Competing with other industries for skilled workers demands competitive wages, comprehensive benefits packages, and a positive work environment.

- Positive Work Environment: Creating a safe, rewarding, and inclusive work environment is essential for attracting and retaining talented individuals.

- Employee Ownership and Profit Sharing: Employee ownership models and profit-sharing programs can boost employee morale and increase loyalty.

- Government Incentives: Government incentives, such as tax breaks and grants, can also play a crucial role in encouraging businesses to invest in their workforce and attract top talent.

Government Policies and Regulations

Government policies and regulations significantly impact the cost and feasibility of all-American production.

Trade Policies and Tariffs

Trade policies and tariffs can have a profound effect on the competitiveness of domestic manufacturing.

- Impact of Tariffs: Tariffs on imported goods can increase the price of foreign-made products, making domestically produced goods more competitive. However, retaliatory tariffs can also negatively impact US exporters.

- Government Subsidies and Tax Incentives: Government subsidies and tax incentives can help offset the higher costs associated with domestic manufacturing.

Environmental Regulations

Meeting stringent environmental regulations can increase production costs, but also promotes sustainability.

- Compliance Costs: Compliance with environmental regulations can be expensive, requiring investment in cleaner technologies and waste management systems.

- Sustainable Manufacturing: Embracing sustainable manufacturing practices can reduce long-term costs and improve the company's environmental footprint.

- Technological Innovation: Meeting environmental regulations can drive technological innovation, leading to more efficient and sustainable production processes.

Conclusion

Achieving true all-American production presents considerable hurdles, including higher labor and material costs, fierce global competition, skilled labor shortages, and a complex regulatory landscape. However, these challenges are not insurmountable. By strategically addressing these issues through targeted investments in infrastructure modernization, robust workforce development programs, and smart government policies that support domestic manufacturing, we can build a stronger and more resilient US manufacturing sector. Investing in automation, fostering innovation in manufacturing processes, and focusing on higher-value-added products will also enhance the competitiveness of all-American production. Let's work together to overcome the challenges and embrace the potential of All-American Production, building a brighter future for American manufacturing. Support all-American made goods and services today!

Featured Posts

-

Suprasti M Ivaskeviciaus Isvaryma Analize Ir Interpretacijos

Apr 29, 2025

Suprasti M Ivaskeviciaus Isvaryma Analize Ir Interpretacijos

Apr 29, 2025 -

Porsche Ownership A Global Comparison Focusing On Australia

Apr 29, 2025

Porsche Ownership A Global Comparison Focusing On Australia

Apr 29, 2025 -

San Franciscos Anchor Brewing Company Announces Closure After 127 Years

Apr 29, 2025

San Franciscos Anchor Brewing Company Announces Closure After 127 Years

Apr 29, 2025 -

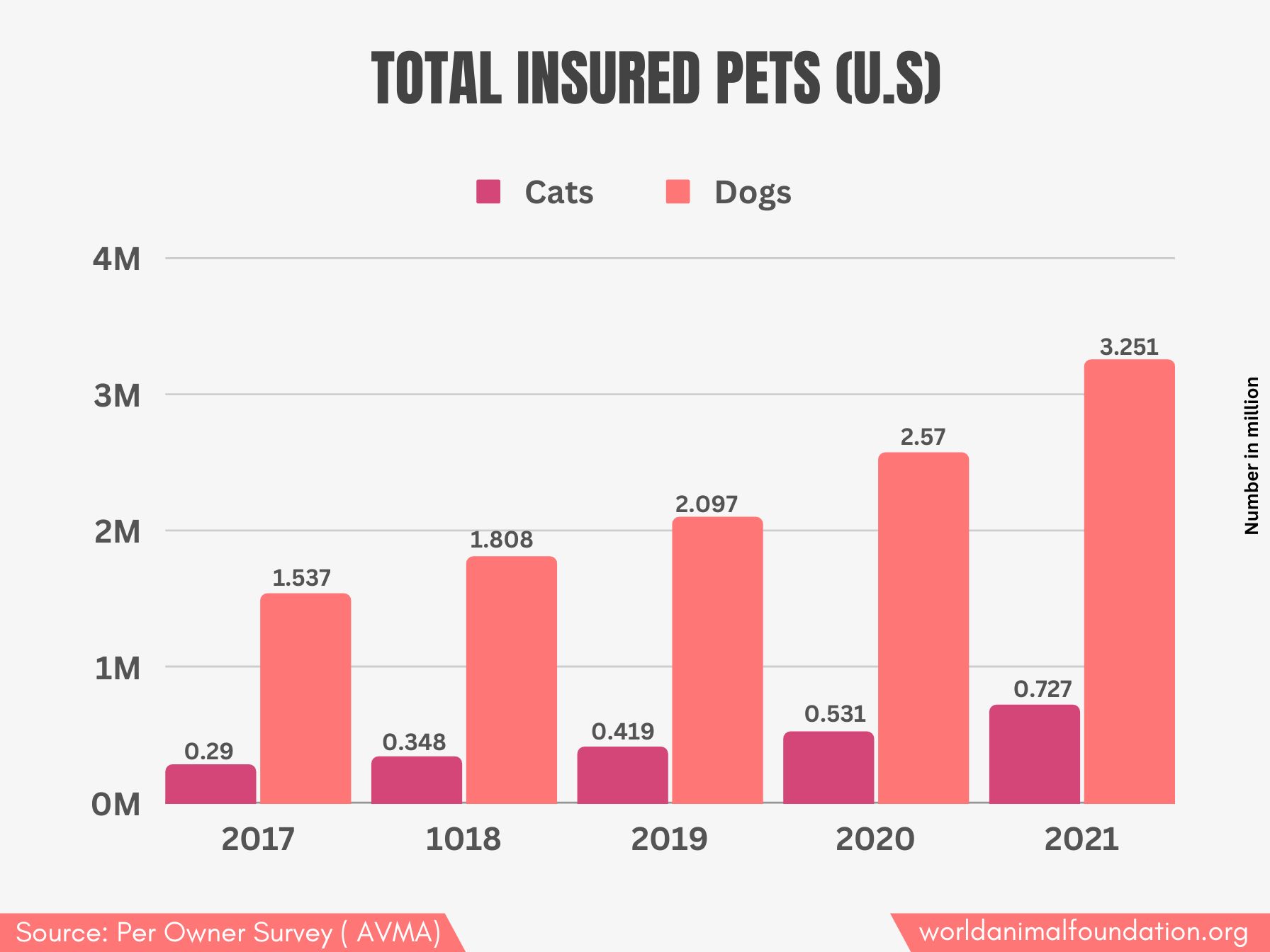

Trumps Potential Pardon Of Pete Rose A Look At The Mlb Betting Ban

Apr 29, 2025

Trumps Potential Pardon Of Pete Rose A Look At The Mlb Betting Ban

Apr 29, 2025 -

Fhi Adhd Medisinens Begrensede Effekt Pa Skoleprestasjoner

Apr 29, 2025

Fhi Adhd Medisinens Begrensede Effekt Pa Skoleprestasjoner

Apr 29, 2025

Latest Posts

-

To Mellon Tis Iatrikis Ypologistes Apo Ines Kai I Parakoloythisi Tis Ygeias

Apr 29, 2025

To Mellon Tis Iatrikis Ypologistes Apo Ines Kai I Parakoloythisi Tis Ygeias

Apr 29, 2025 -

8 Mart Onkokhirurg I Trenor Obedinyavat Sili Za Fitnes I Zdrave Na Grdata

Apr 29, 2025

8 Mart Onkokhirurg I Trenor Obedinyavat Sili Za Fitnes I Zdrave Na Grdata

Apr 29, 2025 -

Iva I Siyana Istoriya Na Uspekha I Ambitsiite

Apr 29, 2025

Iva I Siyana Istoriya Na Uspekha I Ambitsiite

Apr 29, 2025 -

Pripad Unosu Studentky Sony Obnova Konania Na Sude V Stredu

Apr 29, 2025

Pripad Unosu Studentky Sony Obnova Konania Na Sude V Stredu

Apr 29, 2025 -

Marriage Confirmed Iva Ristic Announces Her Incredible Husband

Apr 29, 2025

Marriage Confirmed Iva Ristic Announces Her Incredible Husband

Apr 29, 2025