BYD Case Study: Examining Their Leading Position In EV Battery Manufacturing

Table of Contents

BYD's Vertical Integration Strategy: A Key to Success

BYD's success is significantly attributed to its vertically integrated business model. This strategy provides unparalleled control over the entire supply chain, from raw material sourcing to battery cell production and ultimately, vehicle assembly. Keywords: Vertical Integration, Supply Chain, Cost Efficiency, Battery Production, Raw Material Sourcing.

-

Control over Raw Materials: BYD actively participates in securing essential raw materials like lithium and cobalt, mitigating supply chain risks and price volatility. This direct involvement allows for better cost management and ensures a consistent supply of high-quality materials. For example, BYD has invested heavily in lithium mining and processing, reducing its reliance on external suppliers and securing a competitive advantage.

-

Optimized Production Processes: Vertical integration allows BYD to optimize its production processes across all stages, leading to significant cost efficiencies and improved quality control. This streamlined approach minimizes waste, enhances efficiency, and ensures a faster response to market demands.

-

Minimizing Supply Chain Disruptions: By controlling the entire supply chain, BYD is less susceptible to disruptions caused by external factors such as geopolitical instability or supplier shortages. This resilience is a critical competitive advantage in the volatile global EV battery market.

Innovative Battery Technologies: LFP and Blade Batteries

BYD's technological innovation has been pivotal in its market dominance. Its commitment to research and development has yielded groundbreaking battery technologies, notably Lithium Iron Phosphate (LFP) batteries and its revolutionary Blade Battery. Keywords: LFP Battery, Blade Battery, Battery Technology, Energy Density, Safety, Cost-Effectiveness.

-

Lithium Iron Phosphate (LFP) Batteries: BYD's extensive use of LFP batteries offers several advantages. These batteries are known for their inherent safety due to their thermal stability, and are significantly more cost-effective than other battery chemistries like Nickel Manganese Cobalt (NMC). Their longer lifespan also contributes to reduced overall battery replacement costs. The environmental impact is also lower due to the abundance and easier extraction of the materials used in LFP batteries.

-

Blade Battery: BYD's Blade Battery represents a significant advancement in battery technology. Its unique design, featuring long, flat cells, maximizes space utilization within the vehicle, increasing energy density while maintaining a compact form factor. This innovation provides improved range and performance compared to traditional cylindrical or prismatic battery packs. Furthermore, the Blade Battery boasts exceptional safety features and improved thermal management.

-

Environmental Considerations: Compared to NMC batteries, LFP batteries have a lower environmental impact due to the reduced need for critical and often ethically sourced materials like cobalt. This aligns with the growing demand for sustainable and environmentally responsible EV technologies.

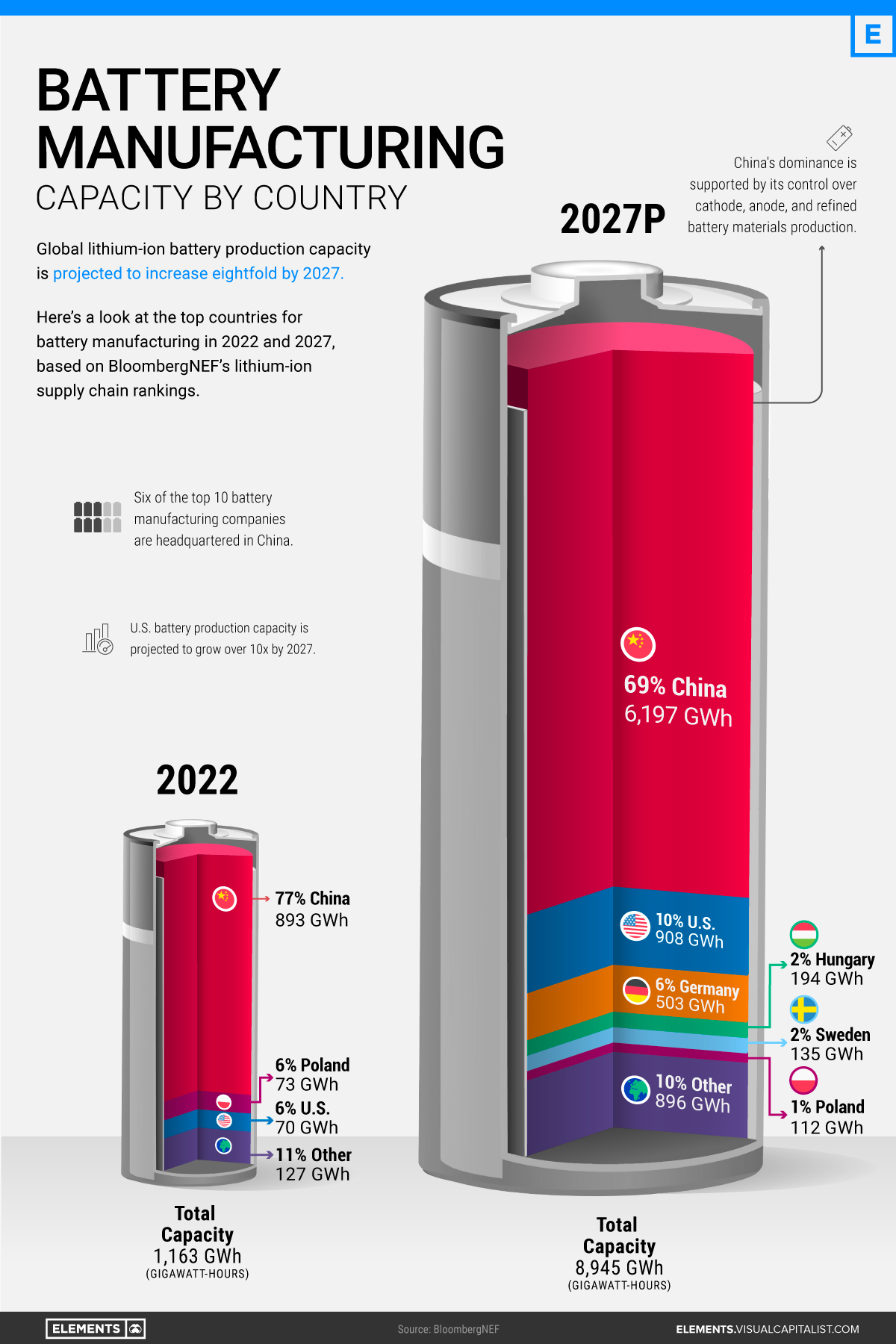

Massive Production Capacity and Global Expansion

BYD boasts an impressive production capacity for EV batteries, consistently expanding its manufacturing capabilities to meet the surging global demand. Keywords: Production Capacity, Manufacturing Scale, Global Expansion, Market Share, EV Industry Growth.

-

Gigafactories and Expansion: BYD has strategically built several gigafactories worldwide, substantially increasing its battery production capacity and ensuring global reach. These facilities are equipped with state-of-the-art manufacturing technologies, optimizing efficiency and output.

-

Market Share Growth: BYD's market share in the global EV battery market is rapidly expanding, reflecting its technological leadership and impressive manufacturing scale. This significant growth underscores its competitive position within the dynamic EV industry.

-

Strategic Partnerships and Investments: BYD's global expansion is driven by strategic partnerships and investments in various regions. These collaborations enable access to new markets, local expertise, and further strengthen its supply chain network.

Challenges and Future Outlook for BYD's EV Battery Dominance

Despite its current success, BYD faces several challenges in maintaining its leading position in the EV battery market. Keywords: Competition, Raw Material Prices, Technological Advancements, Future of EV Batteries, Sustainability.

-

Increasing Competition: The EV battery market is becoming increasingly competitive with new entrants and established players expanding their production capacity. BYD must continuously innovate and improve its efficiency to stay ahead.

-

Fluctuating Raw Material Prices: Price volatility in raw materials such as lithium and cobalt poses a significant risk to profitability. BYD's vertical integration strategy helps mitigate this risk, but price fluctuations remain a concern.

-

Technological Advancements: The rapid pace of technological advancements necessitates ongoing R&D investment to maintain a competitive edge. BYD must continuously innovate to develop even more efficient and higher-performing battery technologies.

Conclusion

This case study has demonstrated BYD's remarkable success in EV battery manufacturing, driven by its vertical integration strategy, innovative battery technologies like LFP and Blade batteries, and substantial production capacity. Despite facing challenges such as increasing competition and fluctuating raw material prices, BYD's proactive approach, commitment to innovation, and global expansion plans position them strongly for continued growth in the booming electric vehicle sector. Learn more about the advancements in BYD EV battery manufacturing and how this industry leader is shaping the future of electric mobility. Explore the latest innovations and stay informed about the ongoing developments in electric vehicle battery technology by following our blog and subscribing to our newsletter.

Featured Posts

-

Miami Heat Fans Turn To Nba Tankathon During The Off Season

May 13, 2025

Miami Heat Fans Turn To Nba Tankathon During The Off Season

May 13, 2025 -

Bezopasnost I Britaniya London Otkryt Dlya Dialoga S Es

May 13, 2025

Bezopasnost I Britaniya London Otkryt Dlya Dialoga S Es

May 13, 2025 -

The Colin Jost Scarlett Johansson Salary Difference A Discussion On Celebrity Earnings

May 13, 2025

The Colin Jost Scarlett Johansson Salary Difference A Discussion On Celebrity Earnings

May 13, 2025 -

Serie A Inter Napoli Atalanta Wie Pakt De Titel

May 13, 2025

Serie A Inter Napoli Atalanta Wie Pakt De Titel

May 13, 2025 -

Salman Khans Biggest Box Office Flop R2 Crore Disaster Directors Career End Actresss Bollywood Exit

May 13, 2025

Salman Khans Biggest Box Office Flop R2 Crore Disaster Directors Career End Actresss Bollywood Exit

May 13, 2025

Latest Posts

-

End Of An Era Pieterburens Seal Rescue Center Closes Releases Last Seals

May 13, 2025

End Of An Era Pieterburens Seal Rescue Center Closes Releases Last Seals

May 13, 2025 -

Schiphol Road And Ferry Traffic Easter And Spring Holiday Peak Days Predicted

May 13, 2025

Schiphol Road And Ferry Traffic Easter And Spring Holiday Peak Days Predicted

May 13, 2025 -

Plan Ahead Peak Travel On Schiphol Roads And Ferries This Easter Weekend

May 13, 2025

Plan Ahead Peak Travel On Schiphol Roads And Ferries This Easter Weekend

May 13, 2025 -

Hip Hop Reacts Tory Lanez And 50 Cent On Megan Thee Stallions Guilty Verdict Prediction

May 13, 2025

Hip Hop Reacts Tory Lanez And 50 Cent On Megan Thee Stallions Guilty Verdict Prediction

May 13, 2025 -

50 Cent And Tory Lanez Weigh In On Predicted Megan Thee Stallion Guilty Verdict

May 13, 2025

50 Cent And Tory Lanez Weigh In On Predicted Megan Thee Stallion Guilty Verdict

May 13, 2025