Electric Motor Innovation: A Path To China-Independent Supply Chains

Table of Contents

Boosting Domestic Electric Motor Manufacturing Capabilities

To break free from reliance on Chinese manufacturers, a concerted effort to bolster domestic electric motor production is paramount. This involves significant investment and strategic planning across multiple sectors.

Investing in R&D and Advanced Manufacturing Technologies

The foundation of a robust domestic electric motor industry lies in substantial investment in research and development (R&D). This includes:

- Next-Generation Motor Technologies: Focus on developing high-efficiency permanent magnet motors (PMMs), switched reluctance motors (SRMs), and other advanced motor designs that offer superior performance and reduced reliance on rare-earth materials. Investing in research into new materials like advanced composites can further reduce reliance on imported materials.

- Advanced Manufacturing Techniques: Adopting advanced manufacturing techniques like additive manufacturing (3D printing) for prototyping and specialized components, and implementing automated assembly lines for mass production, dramatically improves efficiency and reduces reliance on manual labor. This allows for greater precision and faster production cycles, crucial for competitiveness.

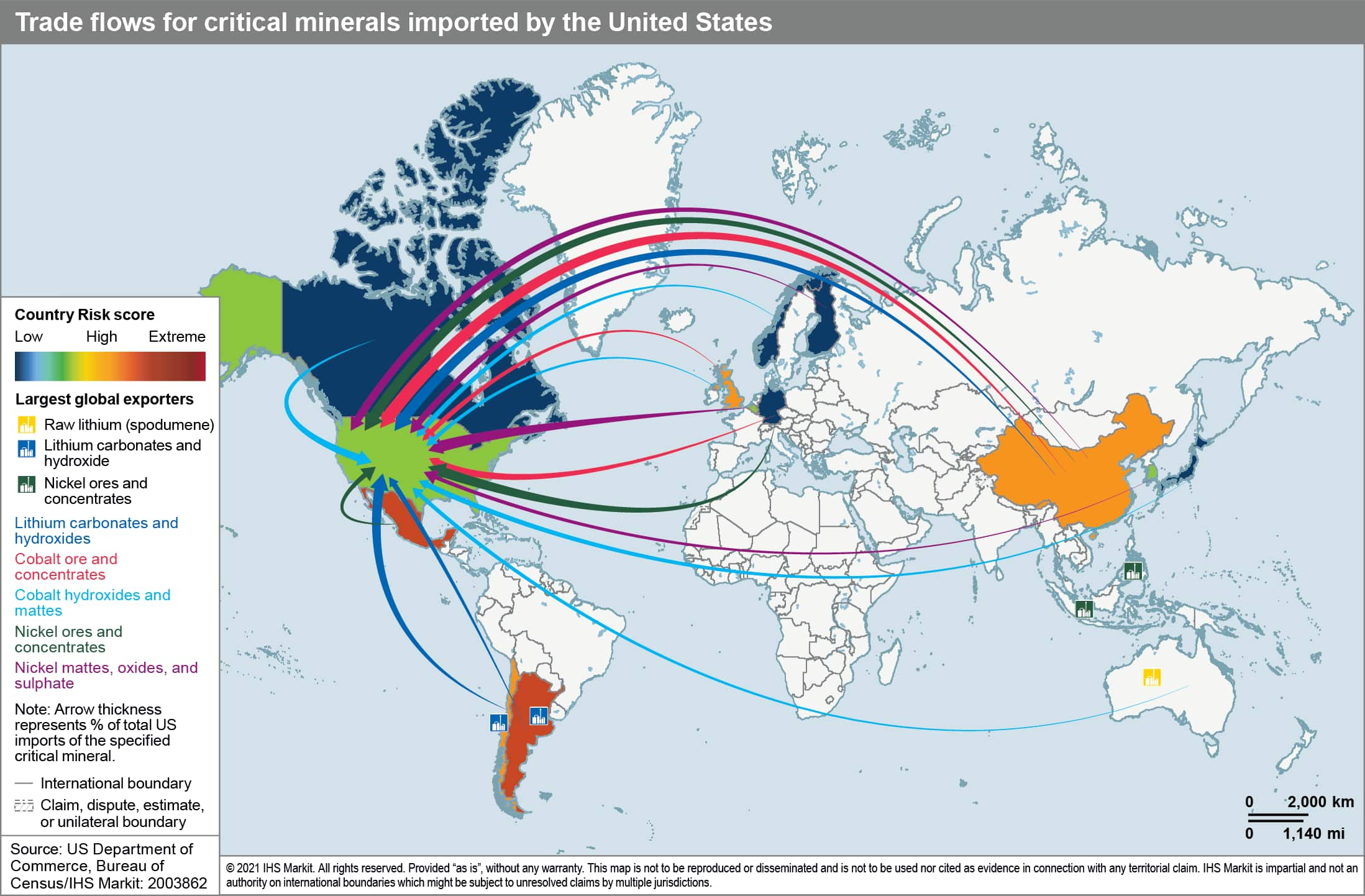

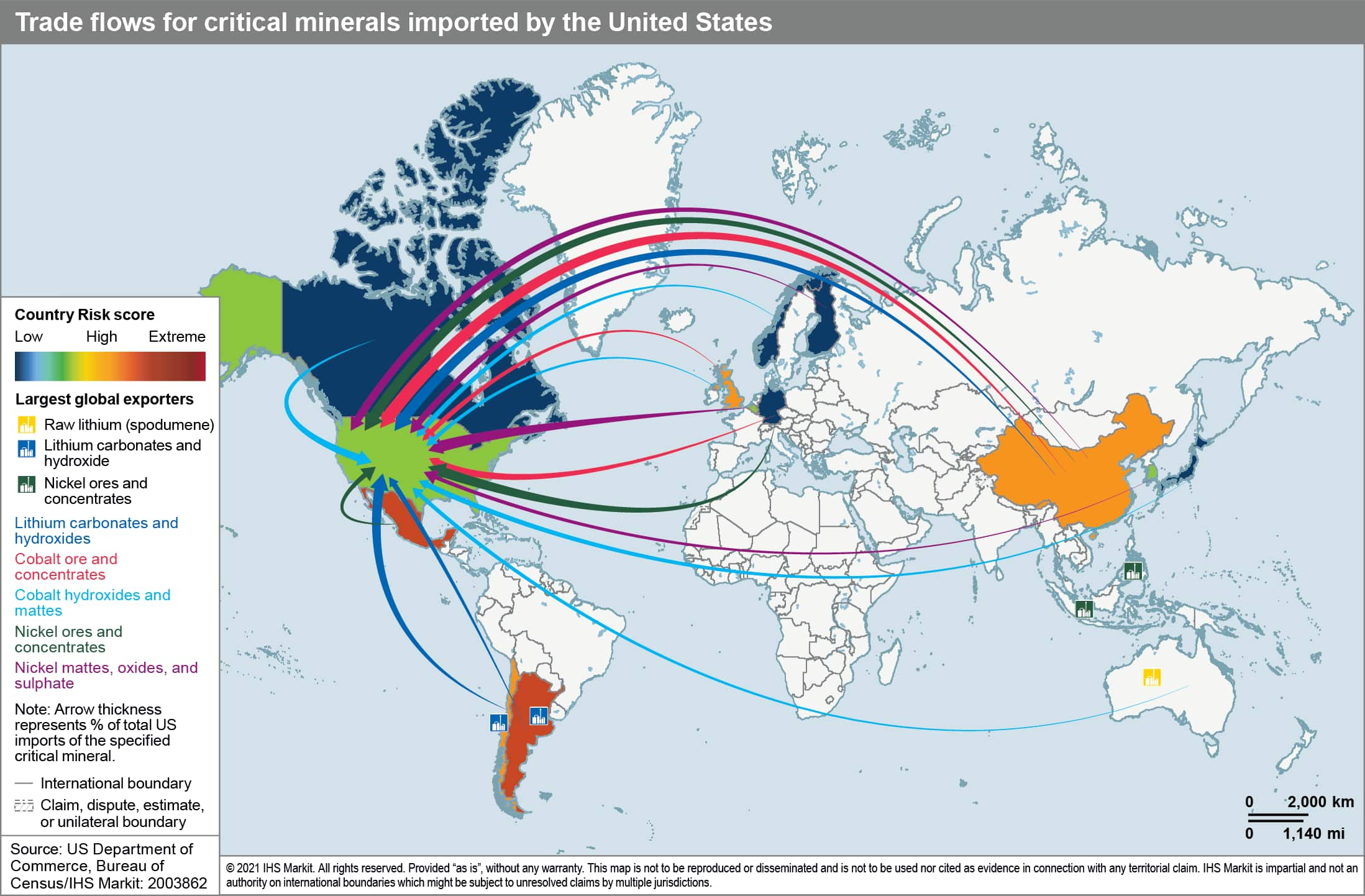

- Domestic Material Sourcing: A critical aspect is reducing dependence on imported raw materials, especially rare earth elements frequently sourced from China. This requires investment in exploration, mining, and processing of domestic resources or securing alternative, reliable international sources for these crucial components. The development of alternative magnet materials is also a key research priority.

Developing a Skilled Workforce

A highly skilled workforce is essential for the success of any advanced manufacturing sector. This necessitates:

- Targeted Education and Training: Investment in specialized education and training programs focused on electric motor design, manufacturing, and maintenance is crucial. This includes vocational training, apprenticeships, and university-level engineering programs with a focus on electric motor technology.

- University-Industry Collaboration: Strong partnerships between universities and research institutions, along with private industry, are vital for fostering innovation and technological breakthroughs. Collaborative research projects can accelerate the development and implementation of new technologies.

- Talent Retention Strategies: Attracting and retaining top talent requires competitive salaries, benefits packages, and career development opportunities within the domestic electric motor industry. This is vital to ensure the sector can attract and keep skilled workers.

Fostering Technological Independence in Electric Motor Design

True independence requires not just manufacturing capability, but also control over the core technology. This involves several strategic actions:

Intellectual Property Protection and Strategic Partnerships

Protecting domestic innovation is key to long-term success:

- Strong IP Protection: Robust intellectual property protection measures are crucial to safeguard domestic innovations in electric motor design and manufacturing processes. This protects investment and prevents technology theft.

- Strategic International Partnerships: Strategic partnerships with leading international companies in electric motor technology can provide access to advanced knowledge and expertise through technology transfer and collaborative research initiatives.

- Open Innovation Models: Promoting open innovation and collaboration within the domestic industry, alongside international partners, fosters knowledge sharing and speeds up the development process.

Diversifying Supply Chains for Critical Components

Reducing reliance on single suppliers is critical for resilience:

- Alternative Sourcing: Identifying and securing alternative sources for critical components, such as magnets, windings, and controllers, from multiple suppliers and geographical locations is vital to mitigate supply chain disruptions.

- Domestic Component Production: Investing in the domestic production of key components reduces vulnerability to external factors, such as geopolitical instability or trade disputes.

- Supply Chain Risk Management: Implementing robust supply chain risk management strategies allows for proactive identification and mitigation of potential disruptions, ensuring business continuity.

Government Policies and Incentives to Support Electric Motor Innovation

Government intervention is crucial to accelerate the transition to China-independent supply chains:

Targeted Funding and Grants for R&D Projects

Direct government support is vital for driving innovation:

- R&D Funding: Significant government funding and grants should be allocated to support R&D projects focusing on advanced electric motor technologies and manufacturing processes.

- Tax Incentives and Subsidies: Tax incentives and subsidies for domestic electric motor manufacturers can significantly boost investment and accelerate the growth of the industry.

- Streamlined Regulatory Processes: A supportive regulatory environment with efficient approval processes for new electric motor technologies can expedite innovation and deployment.

Trade Policies and Protectionist Measures

Strategic trade policies can help protect the nascent domestic industry:

- Targeted Tariffs: Strategic use of tariffs and trade policies can protect domestic manufacturers from unfair competition from foreign producers.

- Trade Agreement Negotiations: Negotiating favorable trade agreements to secure access to essential raw materials and components from reliable international partners is crucial.

- International Collaboration: Developing strategic alliances with like-minded countries can promote cooperation in electric motor technology development and reduce overall dependence on any single nation.

Conclusion

Achieving China-independent supply chains for electric motors requires a multifaceted approach encompassing significant investment in R&D, fostering technological independence, and implementing supportive government policies. By prioritizing domestic manufacturing capabilities, developing a skilled workforce, and diversifying supply chains, nations can secure their future energy needs and reduce vulnerability to geopolitical disruptions. Investing in electric motor innovation is not just a technological imperative but a crucial step toward ensuring national security and economic resilience. Let's work together to create a future where our supply chains for electric motors are secure and independent, free from reliance on a single source. Embrace electric motor innovation – it’s the path to a more secure future.

Featured Posts

-

Newark Airport Flight Disruptions United Airlines Cancellations Due To Faa Staffing

May 04, 2025

Newark Airport Flight Disruptions United Airlines Cancellations Due To Faa Staffing

May 04, 2025 -

The Domenicali Effect Understanding Formula 1s Recent Global Surge

May 04, 2025

The Domenicali Effect Understanding Formula 1s Recent Global Surge

May 04, 2025 -

Price Gouging Allegations Surface After La Fires A Selling Sunset Star Weighs In

May 04, 2025

Price Gouging Allegations Surface After La Fires A Selling Sunset Star Weighs In

May 04, 2025 -

Cusmas Fate Carney And Trumps Crucial Meeting

May 04, 2025

Cusmas Fate Carney And Trumps Crucial Meeting

May 04, 2025 -

Nhl Playoffs 2024 Golden Knights Path To The Stanley Cup Final

May 04, 2025

Nhl Playoffs 2024 Golden Knights Path To The Stanley Cup Final

May 04, 2025

Latest Posts

-

New York New Jersey Connecticut Snow Predictions

May 04, 2025

New York New Jersey Connecticut Snow Predictions

May 04, 2025 -

Official Ufc 314 Bout Order Main Card And Preliminary Fights Announced

May 04, 2025

Official Ufc 314 Bout Order Main Card And Preliminary Fights Announced

May 04, 2025 -

Ufc 314 Full Bout Order Revealed For Main Card And Prelims

May 04, 2025

Ufc 314 Full Bout Order Revealed For Main Card And Prelims

May 04, 2025 -

Ufc 314 Fight Card Main Event Prelims And Bout Order Announced

May 04, 2025

Ufc 314 Fight Card Main Event Prelims And Bout Order Announced

May 04, 2025 -

Improving Traffic Flow In Darjeeling Strategies And Challenges

May 04, 2025

Improving Traffic Flow In Darjeeling Strategies And Challenges

May 04, 2025