EraLow: Eramet's Contribution To Steel Industry Decarbonization

Table of Contents

Understanding EraLow's Role in Low-Carbon Steel Production

EraLow™ represents a significant advancement in low-carbon steelmaking. This process utilizes specifically designed manganese alloys to significantly reduce carbon emissions during steel production compared to traditional methods. The core of EraLow lies in its optimized metallurgical process, improving energy efficiency and minimizing the carbon footprint at each stage.

- Specific percentage reduction in CO2 emissions: EraLow achieves a demonstrable reduction in CO2 emissions, typically exceeding [insert specific percentage or range if available] compared to conventional steelmaking processes. This reduction is a crucial step towards achieving net-zero targets.

- Detailed explanation of the process's efficiency gains: The EraLow process enhances energy efficiency by [explain specific mechanisms, e.g., optimizing heat transfer, reducing energy consumption in specific stages]. This leads to both environmental and economic benefits.

- Patents and intellectual property: Eramet holds [mention relevant patents or intellectual property rights] related to the EraLow process, showcasing its commitment to innovation and technological leadership in sustainable steelmaking.

- Sustainable sourcing of raw materials: Eramet is committed to responsible sourcing of raw materials, ensuring the sustainability of the entire EraLow value chain. This includes [mention specific practices, e.g., traceability initiatives, partnerships with responsible suppliers].

The Environmental Impact of EraLow: A Greener Steel Industry

The environmental benefits of EraLow are substantial, contributing significantly to a greener steel industry and advancing global green steel initiatives. By drastically reducing carbon emissions, EraLow aligns perfectly with the growing demands for environmentally responsible steel production.

- Comparison of EraLow's carbon footprint: A lifecycle assessment comparing EraLow to traditional methods reveals a significantly lower carbon footprint. [Include quantifiable data if available]. This translates to a smaller contribution to climate change.

- Reduced consumption of fossil fuels: The improved energy efficiency of EraLow directly contributes to a reduction in fossil fuel consumption, further mitigating greenhouse gas emissions.

- Certifications and awards: Eramet's commitment to sustainability is reflected in [mention any relevant certifications, e.g., ISO 14001, other relevant industry certifications]. These certifications validate the environmental performance of EraLow.

- Contribution towards global climate goals: EraLow plays a vital role in helping the steel industry meet its targets for greenhouse gas emission reduction, contributing to the achievement of global climate goals set by international agreements.

Economic Advantages of Adopting EraLow: A Sustainable Business Model

Beyond the environmental advantages, adopting EraLow offers compelling economic benefits for steel producers. This sustainable business model combines environmental responsibility with enhanced profitability and competitiveness.

- Potential cost savings: EraLow's improved efficiency translates to potential cost savings in [mention specific areas, e.g., energy consumption, raw material usage]. These savings contribute directly to the bottom line.

- Increased efficiency and productivity gains: The optimized metallurgical process of EraLow leads to increased productivity and reduced production times, further improving economic returns.

- Enhanced market competitiveness: By adopting EraLow, steel producers gain a competitive advantage by offering low-carbon steel products that meet the growing demands of environmentally conscious consumers and businesses. This opens doors to premium markets and pricing.

- Access to carbon credits or other financial incentives: The significant reduction in carbon emissions achieved through EraLow may enable steel producers to access carbon credits or other financial incentives designed to support sustainable business practices.

The Future of EraLow and its Potential for Global Steel Decarbonization

EraLow's future is bright, with significant potential for global impact in steel decarbonization. Eramet is actively pursuing various strategies to expand the reach and effectiveness of this innovative technology.

- Plans for future scaling and expansion: Eramet is committed to scaling up EraLow production to meet the growing global demand for sustainable steel. [mention specific plans, e.g., expansion of production facilities, partnerships with steel producers].

- Potential collaborations: Eramet is actively seeking collaborations with other steel producers and technology providers to further accelerate the adoption of EraLow and its integration into existing steelmaking processes.

- Research and development activities: Ongoing research and development efforts are focused on further improving the efficiency and reducing the cost of the EraLow process, ensuring its long-term competitiveness and sustainability.

- Long-term vision: Eramet envisions EraLow playing a major role in the global transition to a low-carbon steel industry, contributing to a more sustainable and environmentally responsible future.

Conclusion

Eramet's EraLow™ technology represents a significant breakthrough in steel industry decarbonization. Its substantial environmental benefits, coupled with demonstrable economic advantages, make it a compelling solution for steel producers seeking to reduce their carbon footprint and enhance their competitiveness. The future potential of EraLow is vast, promising a global impact on sustainable steel production and a greener future for the metallurgical industry. Learn more about how EraLow™ can help your steel production become more sustainable. Visit the Eramet website to explore the possibilities of low-carbon steel production with EraLow and join the movement toward a greener steel industry.

Featured Posts

-

Michigan Coffee Drinkers Urgent Recall Of Potentially Deadly Coffee Creamer

May 14, 2025

Michigan Coffee Drinkers Urgent Recall Of Potentially Deadly Coffee Creamer

May 14, 2025 -

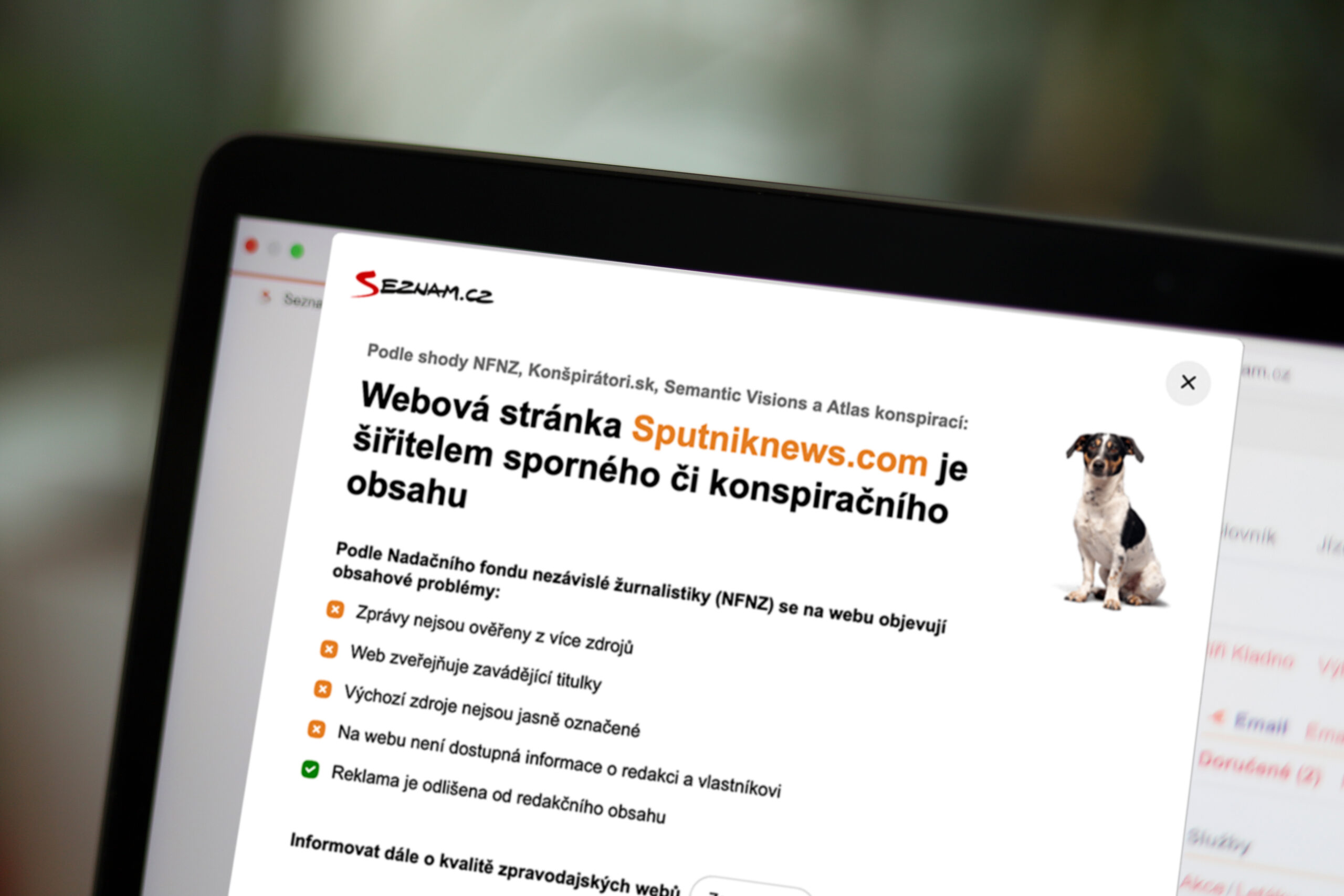

Ct Zablokovala Novinare Deniku N A Seznam Zprav Na Brifinku

May 14, 2025

Ct Zablokovala Novinare Deniku N A Seznam Zprav Na Brifinku

May 14, 2025 -

Eurojackpot Voittojen Puute Nostaa Jaettipottia Ennaetyskorkeuteen

May 14, 2025

Eurojackpot Voittojen Puute Nostaa Jaettipottia Ennaetyskorkeuteen

May 14, 2025 -

Israels Eurovision Song A Spanish Broadcaster Demands Discussion

May 14, 2025

Israels Eurovision Song A Spanish Broadcaster Demands Discussion

May 14, 2025 -

La Liga Espanola Fecha 35 Celta Vs Sevilla Sigue El Partido En Tn

May 14, 2025

La Liga Espanola Fecha 35 Celta Vs Sevilla Sigue El Partido En Tn

May 14, 2025