Eramet's EraLow: Lower-Carbon Manganese Alloy For Steel Production

Table of Contents

The Environmental Benefits of Eramet's eraLow

Traditional manganese alloys used in steel production often have a substantial carbon footprint. Eramet's eraLow represents a significant leap forward in sustainable steelmaking by dramatically reducing CO2 emissions. This reduction stems from optimized production processes and the inherent characteristics of the alloy itself. The environmental benefits are substantial:

-

Significantly lower CO2 emissions during production: Eramet has achieved a considerable percentage reduction in CO2 emissions during the production of eraLow compared to traditional high-carbon manganese alloys. (Specific data on percentage reduction should be inserted here if available from Eramet). This directly contributes to a smaller carbon footprint for the entire steelmaking process.

-

Reduced energy consumption in steelmaking processes: The use of eraLow can lead to lower energy consumption during steel production, further reducing GHG emissions and contributing to operational cost savings.

-

Contribution to a smaller carbon footprint for the final steel product: The reduced emissions during the production of eraLow translate to a smaller carbon footprint for the final steel product, making it a more environmentally responsible choice for manufacturers and consumers alike.

-

Compliance with stricter environmental regulations: As environmental regulations become increasingly stringent globally, eraLow offers steel producers a pathway to meet and exceed these standards, ensuring long-term compliance and sustainability.

-

Enhanced sustainability credentials for steel producers: By using eraLow, steel producers can demonstrate their commitment to environmental responsibility and enhance their sustainability credentials, appealing to environmentally conscious customers and investors.

Enhanced Performance and Properties of eraLow

Beyond its environmental benefits, eraLow also offers enhanced metallurgical performance, leading to improved steel quality. Its unique composition results in superior properties compared to traditional manganese alloys:

-

Improved steel strength and toughness: Eramet's eraLow contributes to the production of steel with increased strength and toughness, enhancing the durability and longevity of the final product.

-

Enhanced weldability and formability: The optimized microstructure of steel incorporating eraLow improves its weldability and formability, making it easier to process and fabricate into various shapes and components.

-

Optimized microstructure for enhanced performance: The specific composition of eraLow results in an optimized microstructure within the steel, leading to superior mechanical properties and overall performance.

-

Consistent and reliable alloy composition: Eramet maintains stringent quality control measures to ensure a consistent and reliable alloy composition in every batch of eraLow, guaranteeing predictable and repeatable results for steel producers.

-

Superior performance in various steel applications: The enhanced properties of eraLow contribute to superior performance in a wide range of steel applications, across various industries.

Applications of eraLow in Steel Production

Eramet's eraLow finds application in a diverse range of steel grades and industries, demonstrating its versatility and broad applicability:

-

High-strength low-alloy (HSLA) steels: EraLow enhances the properties of HSLA steels, making them ideal for applications requiring high strength-to-weight ratios.

-

Advanced high-strength steels (AHSS): The use of eraLow in AHSS contributes to the development of lighter, stronger, and more fuel-efficient vehicles, playing a crucial role in the automotive industry.

-

Construction and infrastructure steel: EraLow can improve the performance and durability of steel used in construction and infrastructure projects, contributing to safer and more resilient structures.

-

Automotive body panels and components: The enhanced properties of steel incorporating eraLow make it suitable for automotive body panels and components, contributing to lighter vehicle weight and improved safety.

-

Other industrial steel applications: The versatility of eraLow extends to numerous other industrial steel applications, where its enhanced performance characteristics are highly beneficial.

Eramet's Commitment to Sustainable Innovation

Eramet's development of eraLow is part of a broader commitment to sustainable innovation and responsible sourcing. The company invests heavily in research and development to create eco-friendly metal alloys and implement sustainable practices throughout its operations:

-

Sustainable mining practices: Eramet is committed to responsible and sustainable mining practices, minimizing its environmental footprint and ensuring the ethical sourcing of raw materials.

-

Investment in R&D for green technologies: Eramet continuously invests in research and development to advance green technologies and develop innovative, sustainable solutions for the metals industry.

-

Traceability and transparency in the supply chain: The company emphasizes traceability and transparency in its supply chain, allowing customers to track the origin and environmental impact of its products.

-

Commitment to reducing the environmental impact of its operations: Eramet is dedicated to reducing the environmental impact of its operations across the entire value chain.

-

Partnerships for a more sustainable future: Eramet actively collaborates with partners across the industry to foster innovation and drive the transition towards a more sustainable future.

Conclusion

Eramet's eraLow represents a significant advancement in sustainable steel production. Its lower carbon footprint, enhanced performance characteristics, and broad applicability across various industries make it a compelling solution for steel producers seeking to minimize their environmental impact. By embracing innovation and a commitment to sustainability, Eramet is playing a key role in shaping a greener future for the steel industry. Discover how Eramet's eraLow can help your company achieve its sustainability goals and improve your steel production processes. Learn more about low-carbon manganese alloys and sustainable steel solutions today! [Link to Eramet's website]

Featured Posts

-

Mission Impossible Dead Reckoning Tom Cruises Risky 140mph Cliff Face Scene

May 14, 2025

Mission Impossible Dead Reckoning Tom Cruises Risky 140mph Cliff Face Scene

May 14, 2025 -

Alkaras Uzor Mladim Igracima Tenisa

May 14, 2025

Alkaras Uzor Mladim Igracima Tenisa

May 14, 2025 -

Forest Awoniyi Surgery After Post Collision

May 14, 2025

Forest Awoniyi Surgery After Post Collision

May 14, 2025 -

Urgence Humanitaire En Haiti Plus De Des Enfants Deplaces Ont Moins De 5 Ans

May 14, 2025

Urgence Humanitaire En Haiti Plus De Des Enfants Deplaces Ont Moins De 5 Ans

May 14, 2025 -

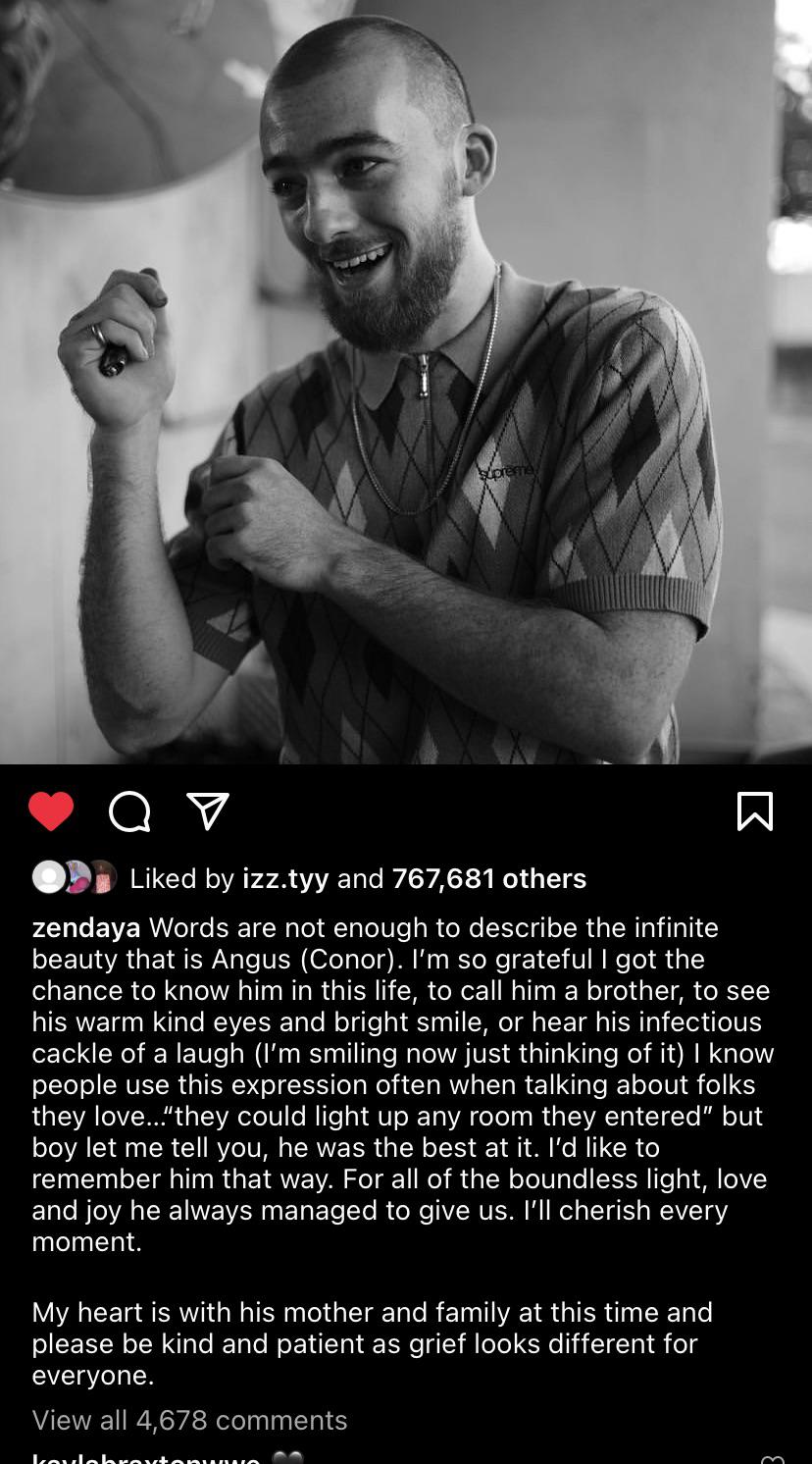

Leaked Euphoria Season 3 Photos Tease Cassies Wedding And Future

May 14, 2025

Leaked Euphoria Season 3 Photos Tease Cassies Wedding And Future

May 14, 2025