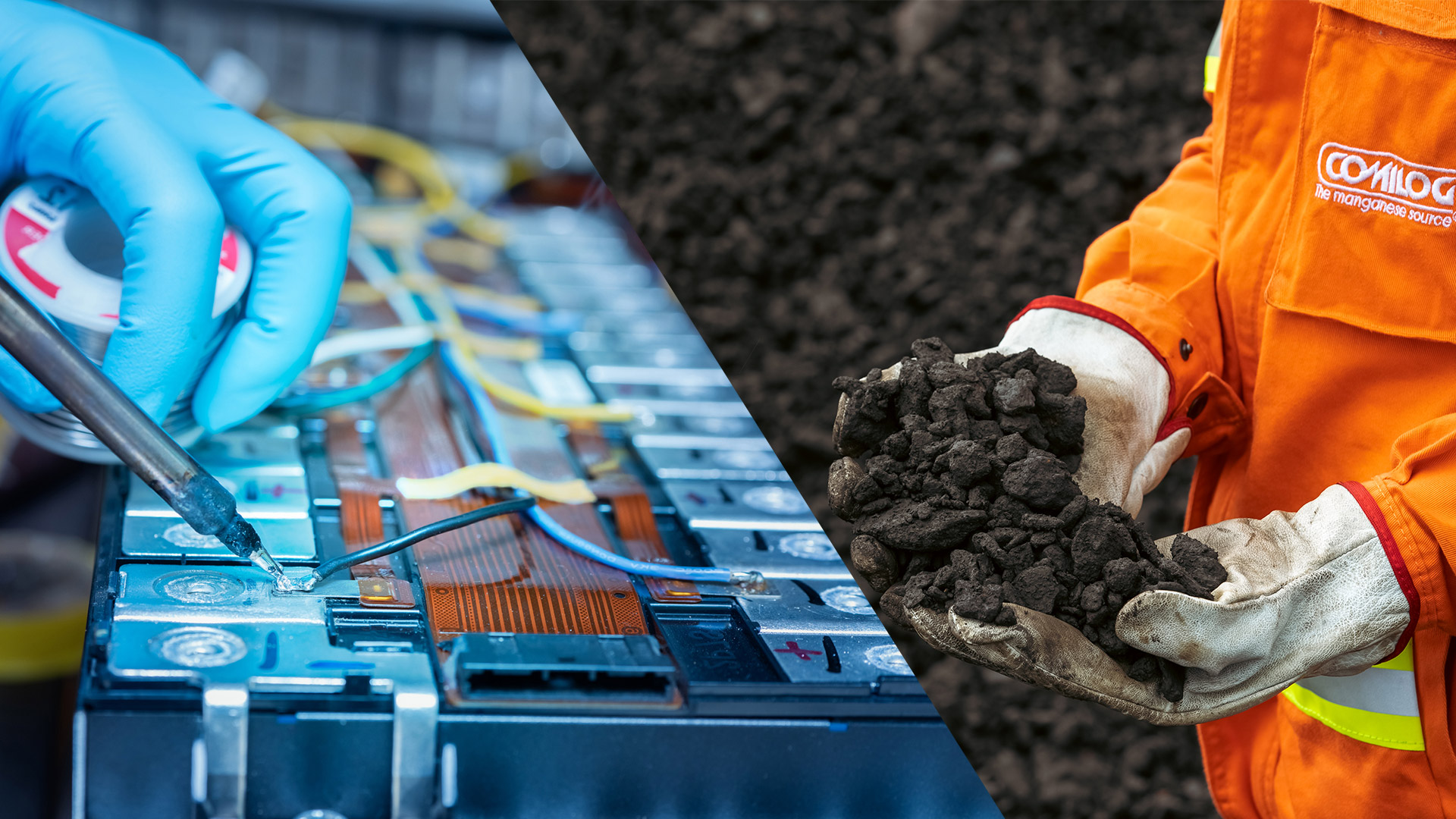

Low-CO2 Manganese Alloy: Eramet's EraLow And The Future Of Steel

Table of Contents

Understanding the Environmental Impact of Traditional Steelmaking

Traditional blast furnace steel production is a significant contributor to global greenhouse gas emissions. The process is inherently energy-intensive, relying heavily on fossil fuels for both heat generation and the reduction of iron ore. Manganese alloys, crucial for steelmaking to enhance its properties, further add to the carbon footprint of the process through their own production methods. This reliance on carbon-intensive processes has placed immense pressure on the steel industry to decarbonize, driving innovation in sustainable steel production methods.

- Significant CO2 Emissions: Blast furnaces emit substantial quantities of CO2 during iron ore reduction and steelmaking processes.

- Manganese Alloy Contribution: The production of traditional manganese alloys also contributes significantly to the overall CO2 emissions associated with steel production.

- Decarbonization Pressure: Growing environmental regulations and consumer demand for sustainable products are forcing the steel industry to adopt greener practices.

Eramet's eraLow: A Low-CO2 Manganese Alloy Solution

Eramet's eraLow represents a significant advancement in sustainable steelmaking. This innovative low-carbon manganese alloy boasts a significantly reduced carbon footprint compared to traditional manganese alloys. Eramet has achieved this reduction through a proprietary process that optimizes energy efficiency and minimizes CO2 emissions at every stage of production. Specific technological advancements remain confidential for proprietary reasons, but the resulting reduced environmental impact is undeniable. Eramet's commitment to sustainability is further evidenced by its ongoing research and development in this area.

- Reduced Carbon Footprint: eraLow's production process leads to a substantially lower CO2 emission profile compared to traditional manganese alloys.

- Technological Advancements: Eramet's proprietary process integrates innovative technologies to improve energy efficiency and minimize waste.

- Sustainability Certifications: While specific certifications may be pending or in development, Eramet's commitment to transparency and sustainable practices are central to eraLow's development.

Benefits of Using eraLow in Steel Production

The adoption of eraLow offers a multitude of benefits beyond its reduced environmental impact. These include improved steel properties, cost-effectiveness, and a significantly reduced carbon footprint.

- Improved Steel Properties: eraLow enhances steel's strength, weldability, and durability, leading to improved performance in various applications. For example, enhanced weldability allows for faster and more efficient manufacturing processes. The increased strength means less material can be used to achieve the same structural integrity, leading to further cost and weight savings.

- Cost-Effectiveness: While the initial cost might be slightly higher, the long-term cost savings from reduced energy consumption and improved material properties often outweigh the initial investment. This is further enhanced by potential reductions in waste and scrap metal.

- Reduced Environmental Impact: The use of eraLow can significantly reduce the CO2 emissions associated with steel production, contributing to a greener and more sustainable industry. Quantifiable reductions will vary depending on the specific application and the scale of implementation.

Market Applications and Future Prospects of eraLow

The applications for eraLow are vast, spanning various sectors demanding high-performance steel. The automotive industry, for example, can leverage eraLow to produce lighter and stronger vehicle components, improving fuel efficiency and reducing emissions. The construction industry can benefit from the enhanced durability and strength of eraLow in infrastructure projects.

- Automotive Steel: eraLow is ideal for high-strength low-alloy (HSLA) steels used in automotive body panels, chassis components, and other structural parts.

- Construction Steel: The enhanced durability and strength of steels produced using eraLow make it suitable for reinforcing bars, structural beams, and other construction applications.

- Future Trends: Eramet is continually researching and developing improvements to eraLow, aiming to further reduce its carbon footprint and enhance its properties. The future will likely see eraLow integrated into advanced steelmaking processes for even greater efficiency.

Conclusion: The Future is Low-CO2: Embracing Eramet's eraLow for Sustainable Steel

Eramet's eraLow offers a compelling pathway towards sustainable steel production. Its reduced carbon footprint, improved steel properties, and cost-effectiveness make it a game-changer for the industry. Adopting low-carbon manganese alloys like eraLow is not merely an environmental responsibility; it's a strategic move towards a more efficient and economically viable future for steel manufacturers. The rise of sustainable manganese alloys, exemplified by eraLow, is essential for achieving a greener, more sustainable future. Learn more about Eramet's eraLow and its potential applications by visiting [link to Eramet's website]. Embrace the future of sustainable steel—embrace eraLow.

Featured Posts

-

Disneys Snow White And The Huntsman Remake Another Box Office Disappointment

May 14, 2025

Disneys Snow White And The Huntsman Remake Another Box Office Disappointment

May 14, 2025 -

Bahnreise Planen Oschatz Nach Saechsische Schweiz

May 14, 2025

Bahnreise Planen Oschatz Nach Saechsische Schweiz

May 14, 2025 -

Liverpools E60m Pursuit A Transfer Race To The Finish Line

May 14, 2025

Liverpools E60m Pursuit A Transfer Race To The Finish Line

May 14, 2025 -

When Is Captain America Brave New World Streaming On Disney Release Date Speculation

May 14, 2025

When Is Captain America Brave New World Streaming On Disney Release Date Speculation

May 14, 2025 -

Unclothed Photo Of Bianca Censori Kanye Wests Controversial Marketing Tactic

May 14, 2025

Unclothed Photo Of Bianca Censori Kanye Wests Controversial Marketing Tactic

May 14, 2025