Nissan-Ford Battery Plant Collaboration: Implications For The EV Industry

Table of Contents

Increased Production Capacity and Economies of Scale

This joint venture will dramatically boost the production capacity of EV batteries, directly addressing the current bottleneck hindering widespread EV adoption. The collaboration promises a significant increase in battery cell output, alleviating supply chain constraints that have plagued the industry.

-

Increased production volume leads to lower per-unit costs: Economies of scale are a significant advantage. By pooling resources and sharing manufacturing infrastructure, both Nissan and Ford can drastically reduce the cost of producing individual battery cells. This translates to lower prices for EVs, making them more accessible to a wider consumer base.

-

Enhanced efficiency through shared resources and expertise: Combining the manufacturing expertise of two automotive giants streamlines processes, optimizes resource allocation, and improves overall efficiency. This synergistic effect reduces waste, minimizes downtime, and maximizes output.

-

Faster deployment of next-generation battery technologies: The combined research and development power allows for quicker development and implementation of advanced battery technologies, such as solid-state batteries, which offer superior energy density, faster charging times, and enhanced safety features. This accelerates the transition to more efficient and sophisticated EVs.

The projected increase in battery cell production is substantial, potentially adding millions of units annually to global capacity. This influx will significantly ease the strain on the current supply chain and pave the way for exponential growth in EV sales. Analysts predict cost savings of up to 20% per battery cell due to economies of scale resulting from this Nissan-Ford Battery Plant Collaboration.

Enhanced Technological Innovation and Development

Beyond increased production, the partnership fosters a breeding ground for technological breakthroughs in battery technology. The pooling of resources and expertise from both companies accelerates research and development in crucial areas.

-

Accelerated research and development in solid-state batteries and other advanced technologies: Joint research initiatives can focus on overcoming the challenges associated with developing and scaling up next-generation battery technologies, such as solid-state batteries, which promise significantly improved performance and safety.

-

Shared knowledge and expertise in battery chemistry and manufacturing processes: The exchange of intellectual property and best practices allows both companies to learn from each other's successes and failures, accelerating the pace of innovation. This collaborative approach fosters a more efficient and effective R&D process.

-

Improved battery performance, longevity, and safety features: This shared knowledge base leads to the creation of more powerful, longer-lasting, and safer batteries, enhancing the overall appeal and reliability of electric vehicles. This directly addresses consumer concerns about EV range and battery lifespan.

The combined strength of Nissan and Ford's research teams is expected to lead to significant advancements in battery chemistry, cell design, and manufacturing processes. The potential for breakthroughs in solid-state battery technology, in particular, is a key driver for excitement surrounding this Nissan-Ford Battery Plant Collaboration.

Impact on the Competitive Landscape of the EV Market

The Nissan-Ford Battery Plant Collaboration has significant implications for the competitive dynamics of the EV market. It creates a powerful new force capable of challenging established players and influencing market share.

-

Increased competitiveness against Tesla and other major players: The combined production capacity and technological advancements give Nissan and Ford a significant advantage in competing with Tesla and other leading EV manufacturers.

-

Potential for decreased battery prices, making EVs more affordable: The economies of scale generated by the joint venture will likely translate into lower battery prices, making electric vehicles more affordable and accessible to a wider range of consumers.

-

Influence on the adoption rate of electric vehicles by consumers: Lower prices and improved battery technology will undoubtedly contribute to increased consumer adoption of electric vehicles, accelerating the transition to sustainable transportation.

This collaboration could lead to a significant shift in market share, particularly impacting smaller EV manufacturers who may struggle to compete with the increased production capacity and technological edge gained by this partnership. The market could witness a consolidation, with larger players gaining even greater dominance.

Supply Chain Diversification and Security

A critical aspect of the Nissan-Ford Battery Plant Collaboration is its contribution to a more resilient and diversified EV battery supply chain.

-

Reduced vulnerability to geopolitical instability and supply chain disruptions: The strategic location of the new plant will help reduce reliance on specific regions, mitigating the risks associated with geopolitical tensions and supply chain disruptions.

-

Enhanced security of battery materials sourcing: The partnership can leverage the combined purchasing power of both companies to secure stable and reliable sources for critical battery materials.

-

Greater stability in battery pricing: A more diversified supply chain reduces the vulnerability to price fluctuations and market volatility, ensuring more stable battery costs for both manufacturers and consumers.

The geographic diversification offered by this collaboration strengthens supply chain resilience, reducing the risk of disruptions caused by geopolitical events, natural disasters, or other unforeseen circumstances. This strategic move strengthens the long-term viability of the EV industry.

Conclusion

The Nissan-Ford battery plant collaboration represents a watershed moment for the EV industry. This joint venture promises to significantly increase production capacity, foster technological innovation, bolster the competitiveness of EVs, and enhance supply chain security. By leveraging their combined resources and expertise, Nissan and Ford are strategically positioning themselves for leadership in the rapidly expanding EV market. This innovative approach could serve as a blueprint for future industry collaborations, accelerating the global transition to sustainable transportation. Continued monitoring of the Nissan-Ford Battery Plant Collaboration and its impact is essential for understanding its long-term effects on the future of electric vehicles.

Featured Posts

-

Wiedersehen Mit Dexter John Lithgow Und Jimmy Smits In Neuen Folgen

May 22, 2025

Wiedersehen Mit Dexter John Lithgow Und Jimmy Smits In Neuen Folgen

May 22, 2025 -

The Goldbergs A Comprehensive Guide To The Sitcoms Humor

May 22, 2025

The Goldbergs A Comprehensive Guide To The Sitcoms Humor

May 22, 2025 -

Dexter Original Sin Steelbook Blu Ray A Collectors Must Have

May 22, 2025

Dexter Original Sin Steelbook Blu Ray A Collectors Must Have

May 22, 2025 -

The Subpoena And Its Impact On The Blake Lively Taylor Swift Friendship

May 22, 2025

The Subpoena And Its Impact On The Blake Lively Taylor Swift Friendship

May 22, 2025 -

Macrons Push For A European First Trade Strategy

May 22, 2025

Macrons Push For A European First Trade Strategy

May 22, 2025

Latest Posts

-

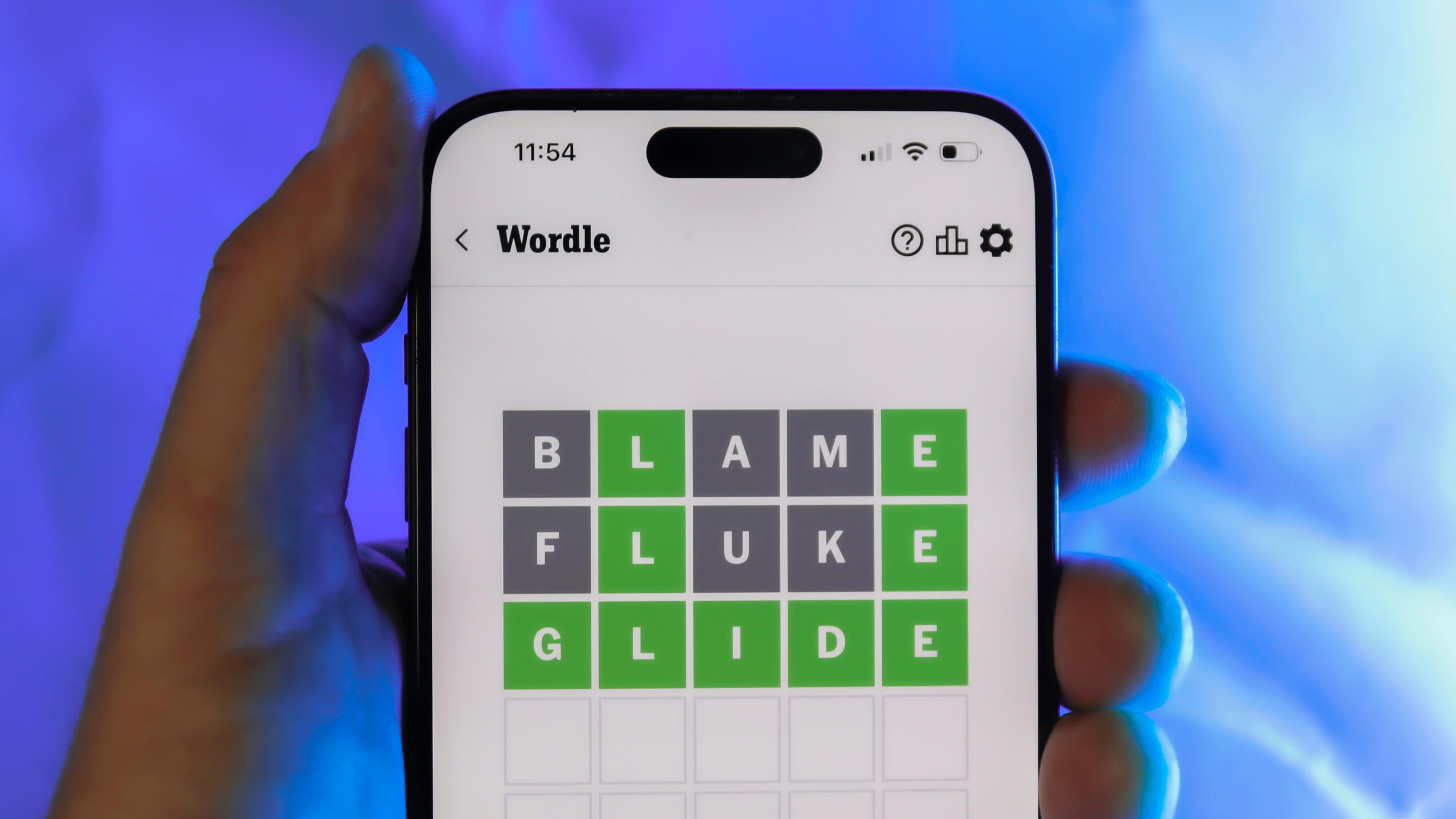

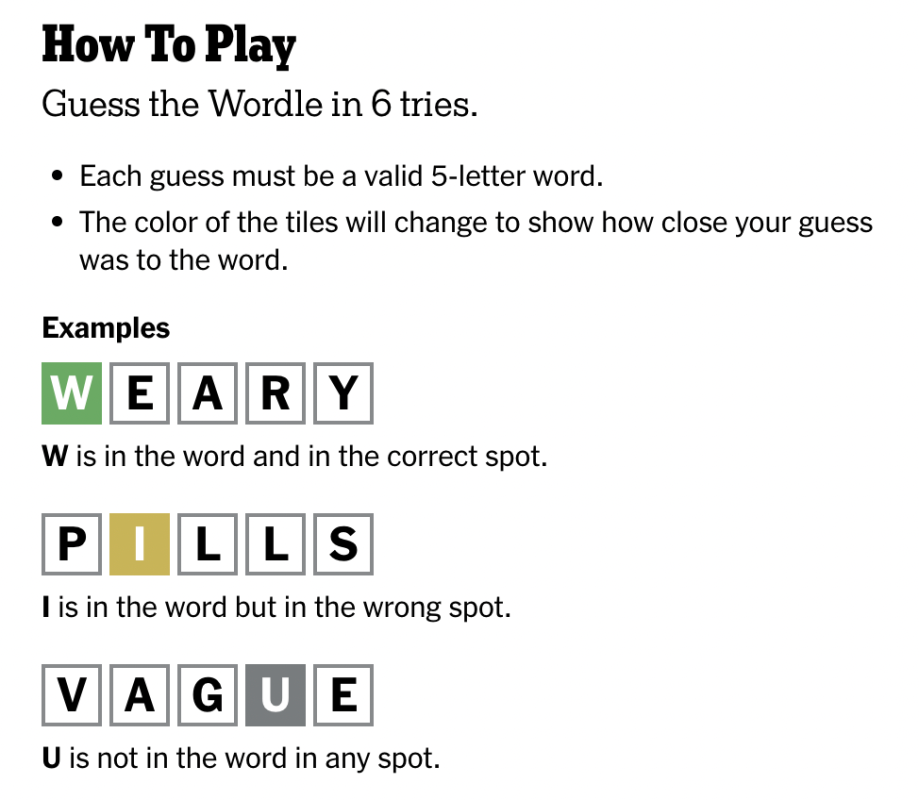

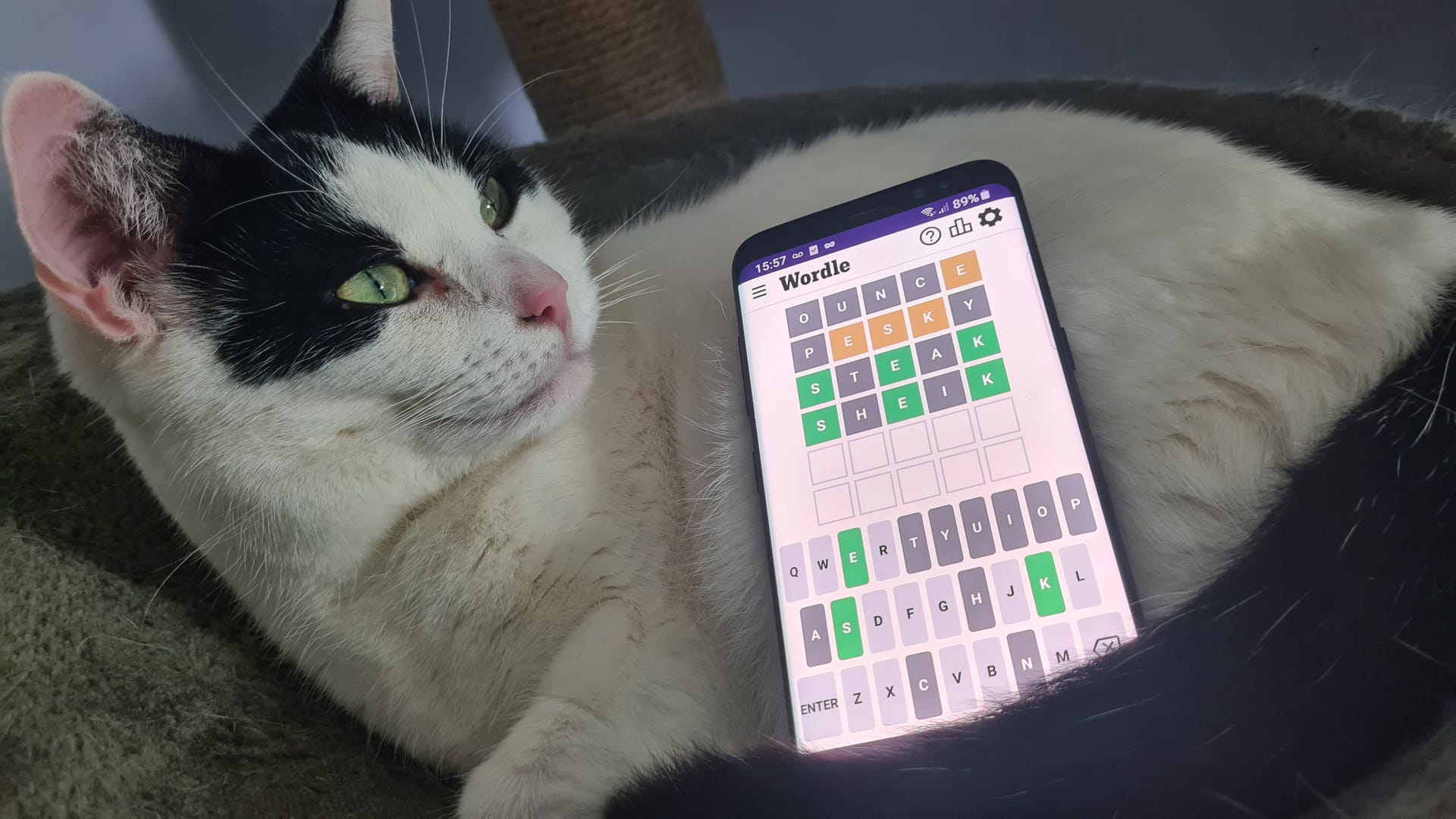

Wordle 1366 Solution Hints And Answer For March 16th Wordle

May 22, 2025

Wordle 1366 Solution Hints And Answer For March 16th Wordle

May 22, 2025 -

Wordle 1366 Answer Solve Todays Wordle Puzzle With Hints

May 22, 2025

Wordle 1366 Answer Solve Todays Wordle Puzzle With Hints

May 22, 2025 -

Solving Todays Wordle March 26 Nyt Wordle Answer Guide

May 22, 2025

Solving Todays Wordle March 26 Nyt Wordle Answer Guide

May 22, 2025 -

Nyt Wordle March 26 Solution And Analysis Of Todays Puzzle

May 22, 2025

Nyt Wordle March 26 Solution And Analysis Of Todays Puzzle

May 22, 2025 -

Todays Wordle March 26 Nyt Wordle Answer And Gameplay

May 22, 2025

Todays Wordle March 26 Nyt Wordle Answer And Gameplay

May 22, 2025