Overcoming Hurdles In Automated Visual Inspection Of Lyophilized Vials

Table of Contents

Challenges in Automated Visual Inspection of Lyophilized Vials

The seemingly simple task of visually inspecting lyophilized vials for defects is surprisingly complex when automated. Several factors contribute to the difficulties in achieving accurate and consistent automated visual inspection using machine vision techniques.

Variations in Lyophilized Cake Appearance

The morphology of the lyophilized cake—its structure, appearance, and color—is highly variable. This inherent variability poses a significant challenge for consistent automated defect detection. Slight changes in the freeze-drying process or formulation can lead to noticeable differences in the final product.

- Variations in cake collapse: Uneven collapse can create irregularities that might be misinterpreted as defects.

- Cracks and fissures: These are common in lyophilized cakes and can be difficult to distinguish from other critical defects.

- Color inconsistencies: Variations in color can stem from differences in formulation or slight variations in the freeze-drying process.

These variations significantly affect image analysis algorithms, leading to a high rate of false positives (flagging non-defective vials) or false negatives (missing actual defects), compromising the reliability of the automated visual inspection process.

Lighting and Shadow Effects

Uneven lighting and shadowing significantly impact image quality, hindering accurate defect detection. The three-dimensional nature of the lyophilized cake further complicates this issue.

- Shadow artifacts: Shadows can obscure real defects or create the illusion of defects where none exist.

- Optimized illumination systems: Careful design of the lighting system is crucial for minimizing shadowing and ensuring uniform illumination across the vial's surface.

Advanced lighting configurations, such as structured lighting or multi-angle illumination, along with sophisticated image pre-processing techniques (e.g., shadow removal algorithms), are crucial for mitigating these lighting-related challenges.

Contamination Detection

Identifying particulate contamination and other foreign materials against the complex background of the lyophilized cake presents a substantial challenge.

- Size and shape variations: Contaminants vary significantly in size and shape.

- Low contrast: The subtle differences in contrast between particles and the lyophilized cake make detection difficult.

- Differentiation challenges: Distinguishing between true contamination and inherent cake irregularities is often problematic.

Advanced image analysis techniques, including machine learning algorithms trained on extensive datasets of contaminated and uncontaminated vials, are essential for improving the sensitivity and specificity of contamination detection in automated visual inspection systems.

Strategies for Improving Automated Visual Inspection of Lyophilized Vials

Overcoming the hurdles in automated visual inspection of lyophilized vials requires a multi-faceted approach encompassing advanced image processing, optimized hardware, and robust data analytics.

Advanced Image Processing Techniques

Advanced image processing algorithms, particularly those leveraging machine learning (ML) and deep learning (DL), are critical for improving defect detection accuracy.

- AI/ML for pattern recognition: AI and ML can learn to identify subtle patterns indicative of defects, even in the presence of variations in cake appearance.

- Image segmentation and filtering: These techniques help isolate regions of interest and enhance the contrast between defects and the background.

- Algorithm optimization: Continuous training and optimization of algorithms using large, representative datasets are vital for achieving high accuracy.

Optimized Hardware and System Design

The choice of hardware components significantly impacts the effectiveness of the automated visual inspection system.

- High-resolution cameras: High-resolution cameras are essential for capturing fine details and subtle defects.

- Suitable lighting configurations: Uniform illumination is achieved through carefully designed lighting systems.

- Robust robotic systems: Precise vial handling and positioning are critical for consistent image acquisition.

Data Analytics and Quality Control

Data analysis plays a critical role in monitoring system performance and identifying areas for improvement.

- Defect rate tracking: Continuous monitoring of defect rates and false positive/negative rates provides valuable insights.

- Process capability analysis: This helps assess the overall performance of the AVI system and identify potential bottlenecks.

- Statistical Process Control (SPC): SPC techniques ensure continuous improvement and maintain consistent quality control.

Conclusion: Overcoming the Hurdles in Automated Visual Inspection of Lyophilized Vials

Automated visual inspection of lyophilized vials presents significant challenges related to cake morphology variability, lighting effects, and contamination detection. However, by implementing advanced image processing techniques, leveraging optimized hardware and system design, and incorporating robust data analytics, pharmaceutical manufacturers can significantly enhance the accuracy and efficiency of their AVI processes. By embracing these strategies and adopting advanced technologies, pharmaceutical manufacturers can overcome the hurdles in automated visual inspection of lyophilized vials, ensuring product quality and patient safety. Investing in improved automated visual inspection systems is crucial for maintaining high standards in pharmaceutical manufacturing and delivering safe and effective medications.

Featured Posts

-

Experience Rotorua Immerse Yourself In New Zealands Cultural Heritage

May 11, 2025

Experience Rotorua Immerse Yourself In New Zealands Cultural Heritage

May 11, 2025 -

Antoine Dulery Raconte Une Mauvaise Rencontre Avec Jean Luc Delarue

May 11, 2025

Antoine Dulery Raconte Une Mauvaise Rencontre Avec Jean Luc Delarue

May 11, 2025 -

Wedding Details Selena Gomez And Benny Blanco Skip The First Dance

May 11, 2025

Wedding Details Selena Gomez And Benny Blanco Skip The First Dance

May 11, 2025 -

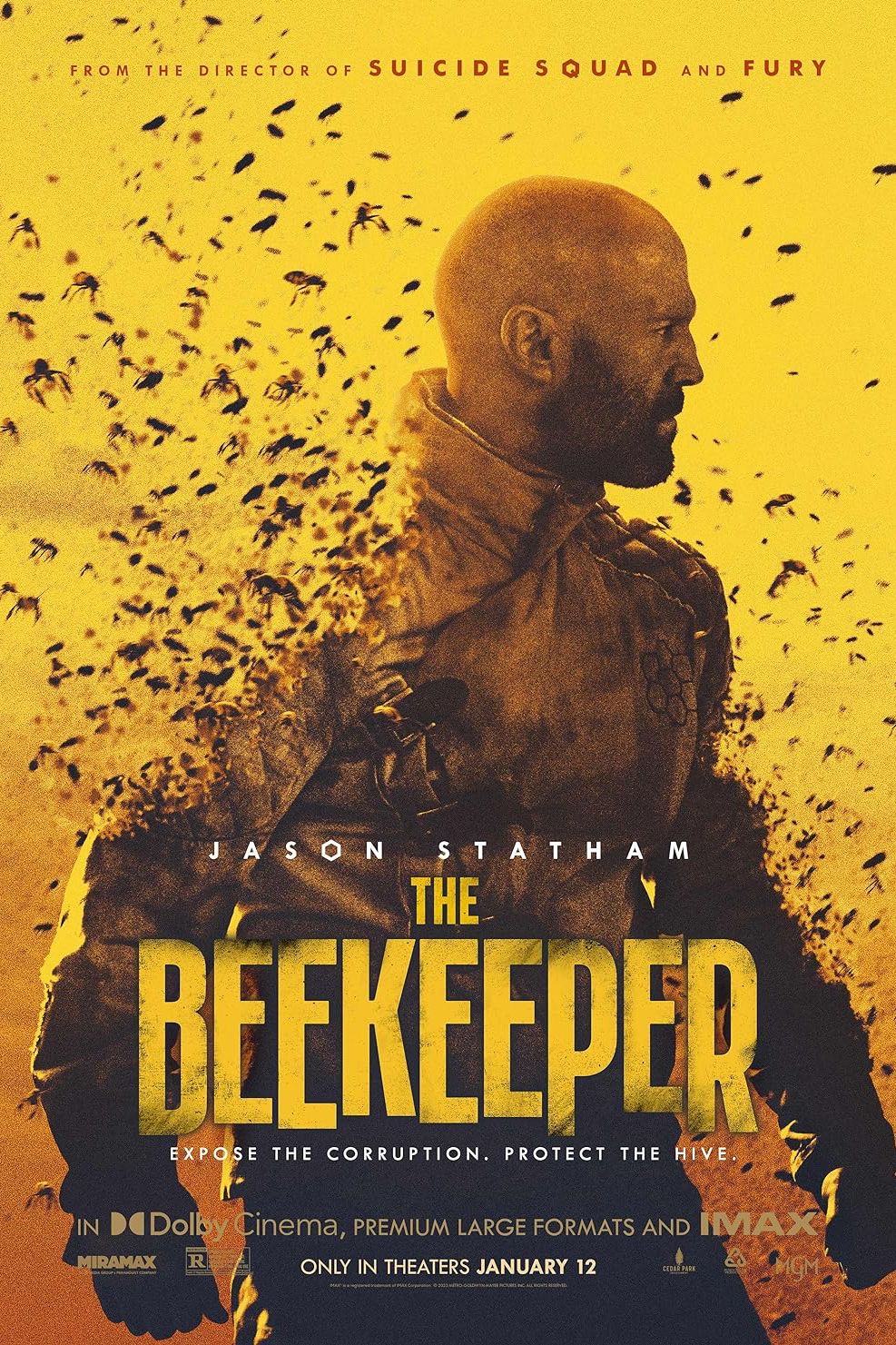

Sylvester Stallones Participation In Jason Stathams Action Movie A Strategic Move

May 11, 2025

Sylvester Stallones Participation In Jason Stathams Action Movie A Strategic Move

May 11, 2025 -

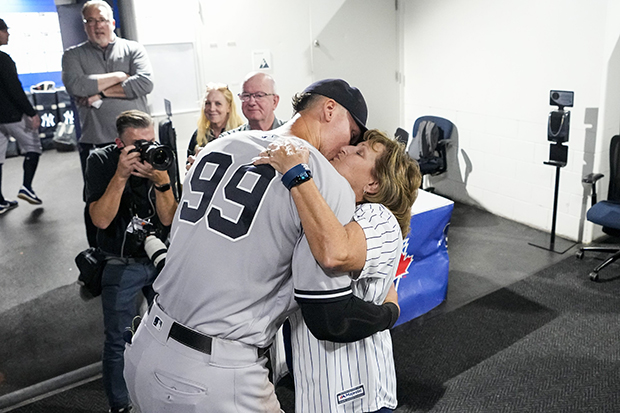

Aaron Judges 2025 Push Up Promise A Deeper Look At The Gesture

May 11, 2025

Aaron Judges 2025 Push Up Promise A Deeper Look At The Gesture

May 11, 2025