Rare Earth Shortages Threaten Tesla's Optimus Robot Production Timeline

Table of Contents

The Critical Role of Rare Earth Elements in Robotics

Rare earth elements (REEs) are essential for the functionality of many modern technologies, and robots are no exception. Optimus, with its advanced sensors, motors, and actuators, relies heavily on these elements for its operation. The performance and efficiency of the robot are directly tied to the availability and quality of these materials.

- Neodymium: A key component in powerful, lightweight permanent magnets vital for Optimus's motors, enabling efficient movement and power.

- Dysprosium: Used in high-strength magnets, crucial for maintaining motor performance even under high temperatures and loads.

- Terbium: Essential for certain types of sensors and actuators, contributing to precision and responsiveness in the robot's movements.

The lack of readily available substitutes for many REEs presents a considerable challenge. Finding alternatives that offer comparable performance and cost-effectiveness remains a significant hurdle for manufacturers like Tesla.

Current Global Rare Earth Supply Chain Issues

The global supply chain for REEs is complex and fraught with challenges. Geopolitical factors play a significant role, impacting both availability and price.

- China's Dominance: China currently controls a significant portion of the global REE mining and processing, creating potential vulnerabilities in the supply chain.

- Ethical Sourcing and Environmental Concerns: The extraction and processing of REEs often raise concerns about environmental damage and ethical labor practices. Ensuring sustainable and responsible sourcing is paramount.

- Market Volatility: Recent disruptions, including geopolitical tensions and increased demand, have led to price volatility in the REE market, adding uncertainty for manufacturers.

The Impact on Tesla's Optimus Production Timeline

The scarcity of REEs poses a substantial risk to Tesla's ambitious Optimus production timeline. Several potential consequences need careful consideration:

- Production Delays: Insufficient supply of REEs could lead to significant delays in the manufacturing process, pushing back the projected launch date.

- Increased Costs: The high demand and limited supply are driving up REE prices, potentially increasing the overall cost of producing Optimus robots.

- Market Competitiveness: Delays and increased costs could impact Tesla's market strategy and competitiveness within the rapidly evolving robotics market.

Alternative Strategies for Tesla

Tesla needs to explore various strategies to mitigate the impact of REE shortages. Potential solutions include:

- Alternative Materials and Designs: Researching and implementing alternative materials or redesigning components to reduce reliance on critical REEs.

- Strategic Partnerships: Collaborating with REE mining companies to secure stable and sustainable supplies.

- Recycling and REE Recovery: Investing in technologies for recycling and recovering REEs from end-of-life products, reducing reliance on virgin materials.

Implications for the Future of Robotics

The challenges faced by Tesla are not unique. The entire robotics industry is susceptible to disruptions caused by REE supply chain issues.

- Bottlenecks in other projects: Similar challenges are likely to affect other robotics companies relying on REEs for their products.

- Need for Diversification: The industry needs to diversify its sourcing of REEs and explore alternative materials to prevent future bottlenecks.

- Advancements in Materials Science: Investment in research and development of new materials that can replace REEs is critical for long-term sustainability.

Conclusion: Securing the Future of Optimus and Robotics

Rare earth shortages pose a significant threat to Tesla's Optimus robot production timeline and the broader robotics industry. Addressing the complex challenges related to REE supply chains—including ethical sourcing, geopolitical factors, and the development of alternative materials—is crucial for ensuring the timely development and successful deployment of advanced robotics technologies. Understanding the challenges presented by rare earth shortages is crucial to ensuring the timely development and success of Tesla's Optimus robot and the future of robotics overall. Learn more about sustainable rare earth element sourcing and the implications for technological advancement by exploring resources available online. The future of robotics depends on it.

Featured Posts

-

Trump Administrations Impact On Elite University Funding Strategies For Survival

Apr 24, 2025

Trump Administrations Impact On Elite University Funding Strategies For Survival

Apr 24, 2025 -

Review Lg C3 77 Inch Oled Tv Performance And Features

Apr 24, 2025

Review Lg C3 77 Inch Oled Tv Performance And Features

Apr 24, 2025 -

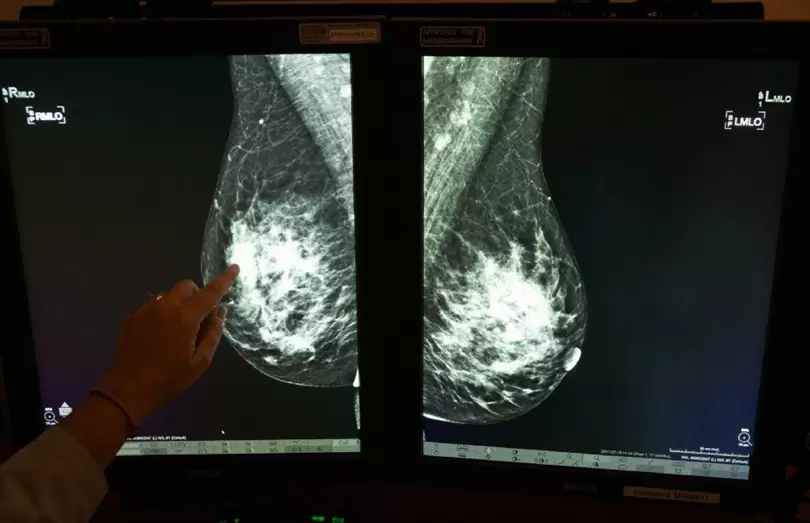

Tina Knowles And Breast Cancer A Missed Mammograms Impact

Apr 24, 2025

Tina Knowles And Breast Cancer A Missed Mammograms Impact

Apr 24, 2025 -

Tarantino I Travolta Nesuglasice Iza Kulisa

Apr 24, 2025

Tarantino I Travolta Nesuglasice Iza Kulisa

Apr 24, 2025 -

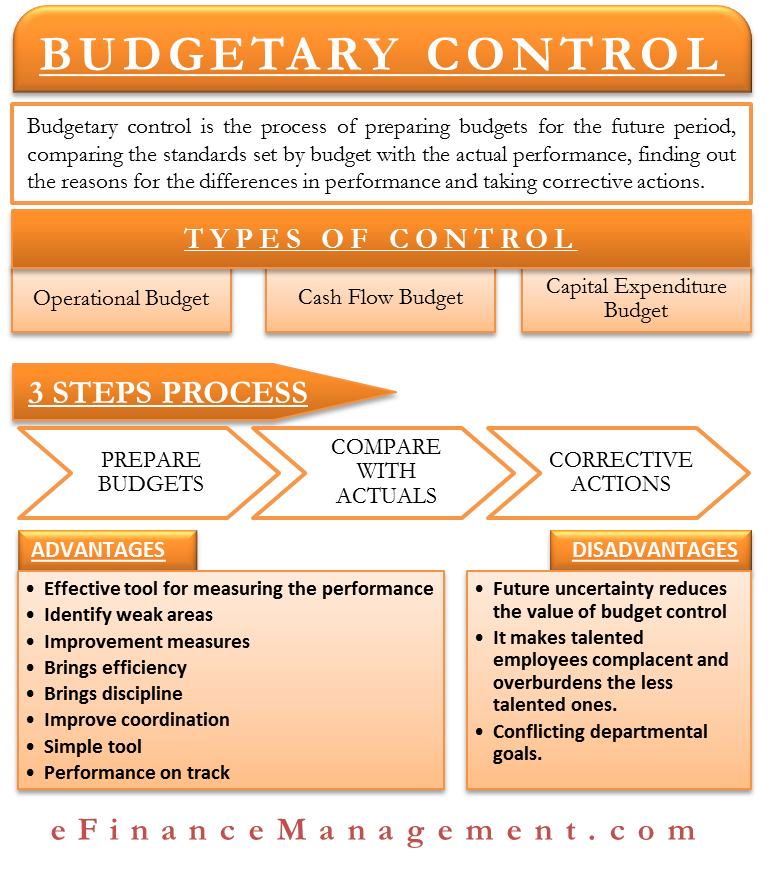

Analysis Trumps Budgetary Changes And Increased Tornado Risk

Apr 24, 2025

Analysis Trumps Budgetary Changes And Increased Tornado Risk

Apr 24, 2025

Latest Posts

-

Chantal Ladesou Biographie Carriere Et Spectacles

May 12, 2025

Chantal Ladesou Biographie Carriere Et Spectacles

May 12, 2025 -

Philippe Candeloro Et Chantal Ladesou Invites D Honneur De La Vente Des Vins De Nuits Saint Georges

May 12, 2025

Philippe Candeloro Et Chantal Ladesou Invites D Honneur De La Vente Des Vins De Nuits Saint Georges

May 12, 2025 -

Une Matinee Exceptionnelle A La Vente Des Vins De Nuits Saint Georges Avec Philippe Candeloro Et Chantal Ladesou

May 12, 2025

Une Matinee Exceptionnelle A La Vente Des Vins De Nuits Saint Georges Avec Philippe Candeloro Et Chantal Ladesou

May 12, 2025 -

Vente Des Vins De Nuits Saint Georges Rencontre Avec Philippe Candeloro Et Chantal Ladesou

May 12, 2025

Vente Des Vins De Nuits Saint Georges Rencontre Avec Philippe Candeloro Et Chantal Ladesou

May 12, 2025 -

Mask Singer 2025 Demasquons L Autruche Analyse Des Indices Et Pronostics

May 12, 2025

Mask Singer 2025 Demasquons L Autruche Analyse Des Indices Et Pronostics

May 12, 2025