Solving OEM Supply Chain Issues: SG Wireless' Enhanced Manufacturing Strategy

Table of Contents

Proactive Component Sourcing and Inventory Management

Effective component sourcing and inventory management are crucial for mitigating supply chain risk. SG Wireless employs a multi-pronged approach to ensure a consistent supply of high-quality components. This strategy addresses the challenges of component shortages and volatile market conditions often impacting OEMs.

-

Strategic partnerships with multiple, geographically diverse suppliers: Diversifying our supplier base across multiple regions minimizes the impact of geopolitical events, natural disasters, or localized disruptions. This approach ensures a reliable flow of components even in challenging circumstances. We carefully select suppliers based on their quality certifications, manufacturing capabilities, and financial stability.

-

Implementation of advanced forecasting models: We leverage sophisticated forecasting models to predict future demand with greater accuracy. These models incorporate historical data, market trends, and seasonality to optimize inventory levels, reducing waste and preventing stockouts. This proactive approach is essential for effective supply chain risk mitigation.

-

Establishment of a robust buffer stock system: While just-in-time manufacturing offers cost advantages, maintaining a strategic buffer stock of critical components provides a safety net against unexpected shortages or delays. This buffer stock allows us to continue production smoothly even during supply chain disruptions, minimizing delays for our OEM partners.

-

Proactive monitoring of global market trends: Our team actively monitors global market trends for potential risks and opportunities. This includes tracking geopolitical events, natural disasters, and industry-specific news that could impact component availability. Early identification of potential disruptions allows for proactive mitigation strategies.

-

Utilizing just-in-time manufacturing principles where appropriate: Where feasible and risk-appropriate, we leverage just-in-time manufacturing principles to minimize inventory holding costs without compromising delivery timelines. This approach requires close collaboration with suppliers and precise demand forecasting.

Flexible and Agile Manufacturing Processes

SG Wireless's flexible and agile manufacturing processes are designed to adapt to the dynamic demands of the modern electronics manufacturing landscape. This adaptability is key to addressing the challenges of demand variability and rapidly changing market conditions.

-

Adoption of flexible manufacturing systems: Our manufacturing lines are designed for flexibility, allowing us to quickly adapt to changing product specifications and production volumes. This agility is crucial for handling unexpected changes in orders or product designs, avoiding costly production stoppages.

-

Implementation of lean manufacturing principles: We apply lean manufacturing principles to eliminate waste throughout our operations. This includes optimizing production flows, reducing lead times, and improving overall efficiency. Lean manufacturing helps us to deliver high-quality products at a competitive cost.

-

Investment in rapid prototyping capabilities: Our investment in rapid prototyping enables quicker product development cycles and shorter lead times for our OEM partners. This allows us to react swiftly to market changes and customer needs, gaining a crucial competitive advantage.

-

Scalable production capacity: We have built scalable production capacity to handle fluctuations in demand without compromising quality or delivery timelines. This means we can smoothly ramp up or down production based on the needs of our OEM partners.

-

Ability to quickly adapt to design changes: Our agile manufacturing system enables rapid adaptation to design changes, ensuring we can quickly incorporate customer feedback and new features into our production process.

Robust Quality Control and Testing Procedures

Maintaining the highest quality standards is paramount for SG Wireless. Our rigorous quality control and testing procedures ensure that every product meets or exceeds our OEM partners’ specifications. This commitment to quality minimizes defects and ensures reliable product performance.

-

Stringent quality control measures at every stage: Quality control is integrated into every phase of our manufacturing process, from incoming material inspection to final product testing. This rigorous approach ensures that defects are identified and corrected early, preventing them from reaching our customers.

-

Implementation of rigorous testing protocols: We utilize comprehensive testing protocols to verify the performance and reliability of our products. This includes functional testing, environmental testing, and stress testing to ensure our products meet the highest industry standards.

-

Continuous improvement initiatives: We are committed to continuous improvement, utilizing data-driven analysis to identify and address quality issues proactively. This ongoing process enables us to constantly enhance our quality control procedures and optimize our manufacturing processes.

-

Utilizing advanced testing equipment: Our investment in state-of-the-art testing equipment allows us to perform highly accurate and efficient testing, ensuring high-quality and reliable results.

-

Commitment to defect reduction: We are dedicated to minimizing defects through proactive process monitoring and continuous improvement. This commitment ensures that our products meet the highest quality standards and deliver exceptional performance.

Transparent Communication and Collaboration

Open and transparent communication is the cornerstone of SG Wireless's relationship with its OEM partners. Effective collaboration helps us address potential challenges proactively and builds trust throughout the supply chain.

-

Open and transparent communication: We maintain open and transparent communication channels with our OEM partners, providing regular updates on production progress, potential challenges, and solutions. This proactive communication helps build trust and ensures everyone is informed.

-

Regular updates: We provide regular updates on production status, potential risks, and planned mitigation strategies. This ensures our OEM partners are always informed and can plan their operations accordingly.

-

Collaborative problem-solving: We embrace a collaborative approach to problem-solving, working closely with our OEM partners to address any supply chain disruptions or challenges. This teamwork helps find optimal solutions that minimize disruption and ensure timely delivery.

-

Strong partner relationships: We build strong, long-term relationships with our key suppliers and partners, fostering trust and collaboration. This collaborative environment ensures a smooth and efficient supply chain.

-

Dedicated customer service team: Our dedicated customer service team provides prompt and effective support to our OEM partners, addressing any concerns or questions promptly and efficiently.

Conclusion

SG Wireless' enhanced manufacturing strategy directly addresses the core challenges facing OEMs in today's volatile supply chain environment. Through proactive component sourcing, flexible manufacturing processes, rigorous quality control, and transparent communication, SG Wireless delivers reliable products and predictable lead times. This holistic approach helps OEMs mitigate risk, reduce costs, and focus on their core business objectives. Contact SG Wireless today to learn more about how our solutions can solve your OEM supply chain issues and deliver a competitive advantage.

Featured Posts

-

Nws Flood Safety Responding To A Current Flood Warning

May 26, 2025

Nws Flood Safety Responding To A Current Flood Warning

May 26, 2025 -

Hasil Latihan Bebas Moto Gp Inggris 2025 Fp 1 Jadwal And Jam Tayang Trans7

May 26, 2025

Hasil Latihan Bebas Moto Gp Inggris 2025 Fp 1 Jadwal And Jam Tayang Trans7

May 26, 2025 -

Detecter Les Fake News L Engagement De La Rtbf Pour La Journee Mondiale Du Fact Checking

May 26, 2025

Detecter Les Fake News L Engagement De La Rtbf Pour La Journee Mondiale Du Fact Checking

May 26, 2025 -

Combattre La Desinformation Avec La Rtbf Journee Mondiale Du Fact Checking

May 26, 2025

Combattre La Desinformation Avec La Rtbf Journee Mondiale Du Fact Checking

May 26, 2025 -

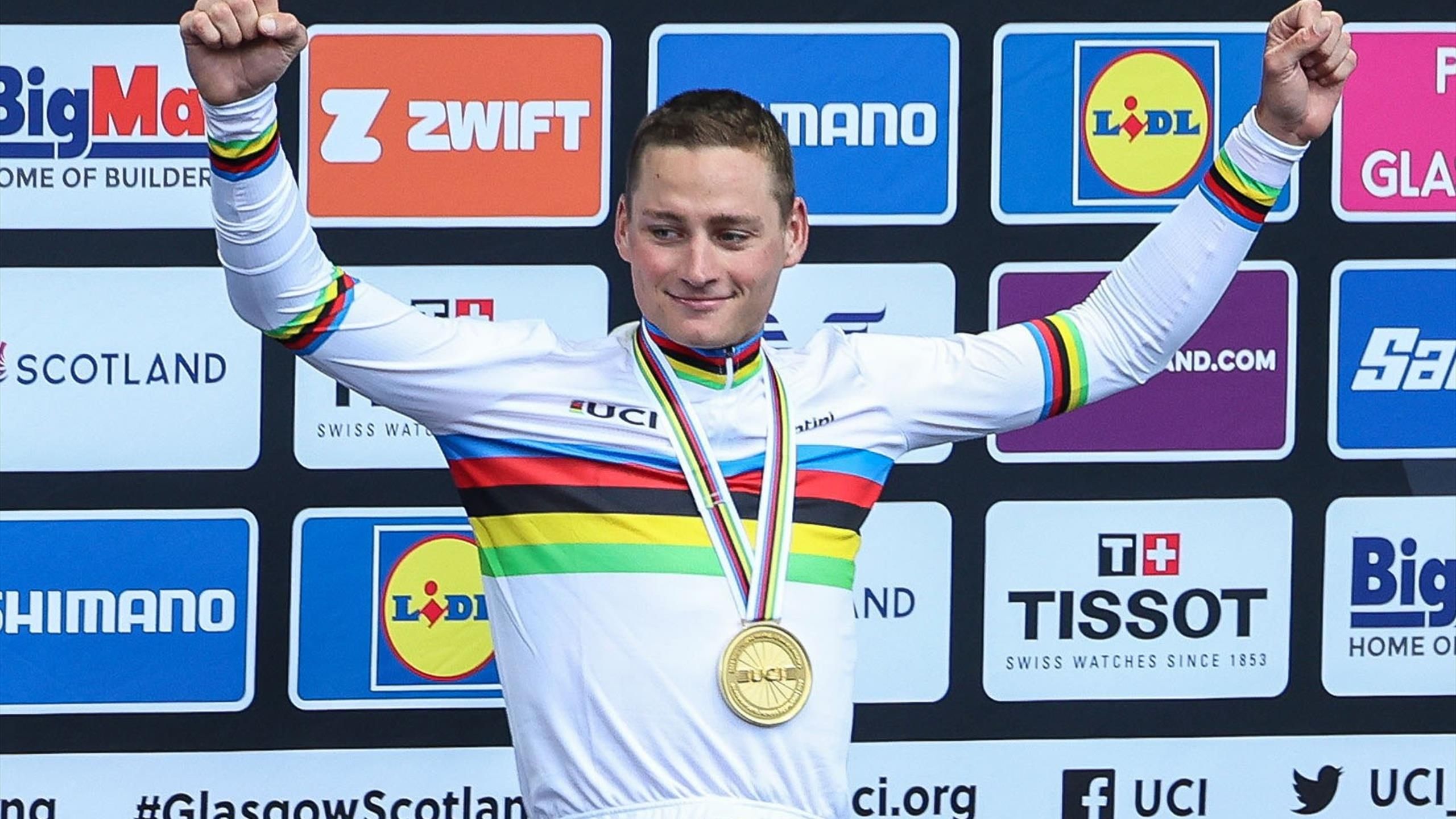

Tour Of Flanders Pogacars Solo Ride Denies Van Der Poel Historic Win

May 26, 2025

Tour Of Flanders Pogacars Solo Ride Denies Van Der Poel Historic Win

May 26, 2025

Latest Posts

-

Bangladeshinfo Com The Ultimate Resource For Bangladesh Information

May 27, 2025

Bangladeshinfo Com The Ultimate Resource For Bangladesh Information

May 27, 2025 -

Exploring Bangladesh With Bangladeshinfo Com

May 27, 2025

Exploring Bangladesh With Bangladeshinfo Com

May 27, 2025 -

Unlocking Bangladesh A Guide To Using Bangladeshinfo Com

May 27, 2025

Unlocking Bangladesh A Guide To Using Bangladeshinfo Com

May 27, 2025 -

Bangladeshinfo Com Comprehensive Guide To Bangladesh

May 27, 2025

Bangladeshinfo Com Comprehensive Guide To Bangladesh

May 27, 2025 -

Bangladeshinfo Com Your Gateway To Bangladesh Information

May 27, 2025

Bangladeshinfo Com Your Gateway To Bangladesh Information

May 27, 2025