Sustainable Steel Production: Eramet's EraLow Manganese Alloy Solution

Table of Contents

The Environmental Impact of Traditional Steelmaking

Traditional steel production methods carry a substantial environmental burden. The process is inherently energy-intensive and relies heavily on unsustainable practices, leading to significant environmental consequences.

High Energy Consumption

Traditional steel production relies heavily on blast furnaces, which require vast amounts of energy, primarily derived from fossil fuels. This dependence on fossil fuels contributes significantly to CO2 emissions and exacerbates climate change.

- Increased reliance on fossil fuels for energy: The high energy demand necessitates a substantial input of coal and coke, leading to significant carbon emissions.

- High energy costs impacting the final product price: The substantial energy requirements translate to increased production costs, ultimately impacting the final price of steel products.

- Significant contribution to greenhouse gas emissions: Blast furnaces are major sources of greenhouse gas emissions, contributing significantly to global warming.

Manganese Ore Sourcing and Processing

The extraction and processing of manganese ore, a critical component in steelmaking, also have significant environmental consequences.

- Mining impacts on local ecosystems and biodiversity: Manganese mining can lead to habitat destruction, soil erosion, and water pollution, negatively impacting local ecosystems and biodiversity.

- Waste generation during manganese ore processing: The refining process generates substantial amounts of waste, requiring proper management to minimize environmental damage.

- Transportation emissions associated with ore delivery: Transporting manganese ore from mines to steel mills generates considerable greenhouse gas emissions, adding to the overall carbon footprint.

Eramet's eraLow: A Sustainable Solution

Eramet's eraLow manganese alloy offers a groundbreaking approach to sustainable steel production, directly addressing the environmental challenges associated with traditional methods.

Reduced Manganese Content

eraLow alloys significantly reduce the amount of manganese required in steel production without compromising the final product's quality or mechanical properties. This reduction has far-reaching environmental benefits.

- Lower manganese content leading to less ore extraction and processing: The reduced manganese demand minimizes the environmental impact of manganese mining and processing.

- Reduced transportation needs due to decreased manganese demand: Less manganese ore needs to be transported, leading to a significant reduction in transportation-related emissions.

- Potential for using recycled manganese sources: The lower manganese requirement opens up opportunities to utilize recycled manganese, further reducing the demand for newly mined ore.

Improved Energy Efficiency

The lower manganese content in eraLow alloys contributes to improved energy efficiency during steelmaking. This results in reduced energy consumption and, consequently, lower emissions.

- Optimized melting processes leading to energy savings: The unique composition of eraLow alloys allows for optimized melting processes, requiring less energy input.

- Reduced fuel consumption in the blast furnace or electric arc furnace: The efficiency gains translate to a reduction in fuel consumption in steelmaking furnaces.

- Lower carbon dioxide emissions due to reduced energy needs: Reduced energy consumption directly translates to lower carbon dioxide emissions, contributing to a smaller carbon footprint.

Enhanced Steel Properties

Despite the reduced manganese content, eraLow alloys maintain or even enhance certain desirable steel properties, ensuring the quality and performance expected in various applications.

- Comparable or superior mechanical properties to traditional steel grades: eraLow alloys offer mechanical properties comparable to or even superior to those of traditional steel grades.

- Improved weldability and formability for certain applications: In some cases, eraLow alloys exhibit improved weldability and formability, making them suitable for a wider range of applications.

- Maintains quality standards necessary for various industrial sectors: The high-quality properties of eraLow alloys meet the rigorous standards demanded by diverse industrial sectors.

Benefits of Choosing Sustainable Steel Production with eraLow

Choosing Eramet's eraLow for sustainable steel production offers a multitude of advantages, impacting environmental sustainability, cost-effectiveness, and technological leadership.

Environmental Responsibility

Adopting eraLow contributes significantly to a more environmentally responsible approach to steel manufacturing.

- Meeting corporate sustainability goals and ESG criteria: eraLow helps companies meet their sustainability goals and Environmental, Social, and Governance (ESG) criteria.

- Enhanced brand image through responsible sourcing and manufacturing: Using eraLow enhances a company's brand image by demonstrating a commitment to sustainable practices.

- Compliance with increasingly stringent environmental regulations: eraLow helps companies comply with ever-tightening environmental regulations worldwide.

Cost Savings

The transition to eraLow can lead to substantial cost savings in the long run.

- Reduced manganese ore procurement costs: The lower manganese requirement reduces the cost of raw materials.

- Lower energy bills during steel production: Improved energy efficiency leads to lower energy consumption and reduced energy bills.

- Increased profitability due to reduced operating expenses: Overall, the combination of reduced raw material and energy costs boosts profitability.

Innovation and Technological Advancement

Embracing eraLow signifies a commitment to innovation and technological advancement in sustainable steel production.

- Investment in innovative technologies for sustainable steelmaking: Using eraLow represents an investment in advanced technologies for environmentally responsible steelmaking.

- Competitive advantage through the adoption of cutting-edge solutions: Adopting eraLow provides a competitive advantage by demonstrating leadership in sustainable practices.

- Leadership role in the transition to a more sustainable steel industry: Companies using eraLow play a leading role in transforming the steel industry towards sustainability.

Conclusion

Eramet's eraLow manganese alloy represents a significant advancement in sustainable steel production. By reducing manganese content and improving energy efficiency, eraLow offers a practical and effective way to lower the environmental impact of steel manufacturing without compromising quality or performance. This innovative solution provides numerous benefits, including reduced greenhouse gas emissions, cost savings, and a strengthened commitment to environmental responsibility. Companies looking to improve their sustainability profile and embrace environmentally friendly practices should strongly consider adopting Eramet's eraLow solution for their sustainable steel production needs. Learn more about how to incorporate sustainable steel production and the benefits of eraLow by contacting Eramet today.

Featured Posts

-

Manganiellos Nonna A Look At Italian Heritage And Family

May 14, 2025

Manganiellos Nonna A Look At Italian Heritage And Family

May 14, 2025 -

Conquer Pokemon Ash Gray A Detailed Walkthrough

May 14, 2025

Conquer Pokemon Ash Gray A Detailed Walkthrough

May 14, 2025 -

Where To Find And Avoid Banned Candles In Canada Etsy Walmart Amazon

May 14, 2025

Where To Find And Avoid Banned Candles In Canada Etsy Walmart Amazon

May 14, 2025 -

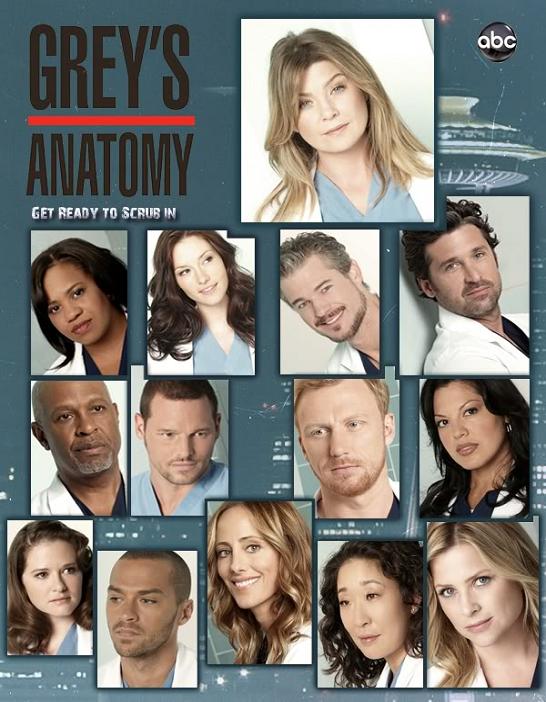

Amiotrofichna Lateralna Skleroza Aktor Ot Anatomiyata Na Grey I Euforiya Bolen

May 14, 2025

Amiotrofichna Lateralna Skleroza Aktor Ot Anatomiyata Na Grey I Euforiya Bolen

May 14, 2025 -

Transfer Huijsen Real Madrid Betaalt Recordbedrag

May 14, 2025

Transfer Huijsen Real Madrid Betaalt Recordbedrag

May 14, 2025