TBS Safety & Nebofleet Partnership Automates Workboat Safety

Table of Contents

Enhanced Communication and Real-time Monitoring with Nebofleet

Nebofleet's cutting-edge technology forms the bedrock of this enhanced workboat safety system. Its real-time vessel tracking and communication capabilities provide unparalleled situational awareness. This improved visibility allows for proactive decision-making, reducing reaction times to critical events and minimizing potential risks. The system offers:

- GPS tracking and location monitoring: Constant monitoring of vessel positions, enabling precise tracking of fleets and individual workboats.

- Automated alerts for critical events: Instant notifications for incidents such as man overboard situations, equipment malfunctions, or deviations from planned routes. These automated alerts ensure swift responses, crucial for mitigating potential hazards.

- Instant communication between vessels and shore teams: Seamless communication channels facilitate quick information exchange, coordinating rescue efforts and enabling efficient problem-solving.

- Integration with other safety systems: Nebofleet seamlessly integrates with existing safety systems, creating a comprehensive and unified safety network. This integration enhances data analysis and improves the overall effectiveness of safety protocols. This powerful combination of vessel tracking, real-time monitoring, and advanced communication systems dramatically improves situational awareness, which is key to preventing accidents.

Streamlined Safety Procedures with TBS Safety's Software Integration

TBS Safety's robust software seamlessly integrates with Nebofleet's data, automating many crucial workboat safety procedures. This integration streamlines safety checks, inspections, and reporting, reducing human error and ensuring compliance. Key benefits include:

- Automated safety checklist completion: Digital checklists guide crew members through safety procedures, ensuring consistent adherence to established protocols.

- Digital documentation of safety procedures: All safety-related documentation is stored securely and digitally, eliminating the need for paper-based records and providing easy access to information.

- Real-time reporting of incidents and near misses: Immediate reporting ensures timely investigation and preventative measures. This proactive approach minimizes the likelihood of similar incidents recurring.

- Simplified compliance with safety regulations: The automated system helps organizations effortlessly meet stringent industry regulations, reducing the administrative burden associated with compliance. This integration of safety management systems and digital documentation makes safety checks more efficient and ensures full compliance with safety regulations.

Improved Efficiency and Reduced Operational Costs Through Automation

The automation provided by the TBS Safety and Nebofleet partnership significantly improves operational efficiency and reduces costs. By streamlining processes and reducing paperwork, valuable time and resources are freed up. This translates into:

- Reduced administrative overhead: Automated reporting and documentation significantly lessen the administrative workload, freeing up personnel for other crucial tasks.

- Faster response times to emergencies: Real-time alerts and enhanced communication enable rapid responses to emergencies, minimizing potential damage and improving safety outcomes.

- Improved resource allocation: Data-driven insights from the system allow for optimized resource allocation, maximizing efficiency and minimizing waste.

- Lower insurance premiums due to improved safety record: A demonstrably improved safety record often leads to lower insurance premiums, providing significant cost savings in the long run. These efficiency gains and cost savings are a direct result of proactive risk mitigation and improved resource management.

Case Studies: Real-World Examples of Improved Workboat Safety

The impact of the TBS Safety and Nebofleet partnership is evident in real-world applications. Here are a couple of examples (note: replace with actual data if available):

- Case Study 1: A fishing fleet utilizing the system experienced a 25% reduction in near misses over a six-month period, highlighting the effectiveness of proactive safety measures.

- Case Study 2: In a recent man overboard situation, the automated alert system enabled a swift response, resulting in a successful rescue within 10 minutes, demonstrating the system's life-saving potential. These success stories underscore the tangible benefits of improved safety records and faster response times.

Conclusion: TBS Safety & Nebofleet: The Future of Workboat Safety

The partnership between TBS Safety and Nebofleet represents a significant advancement in workboat safety. By combining real-time monitoring, automated safety procedures, and enhanced communication, this collaboration dramatically improves safety outcomes, boosts efficiency, and reduces operational costs. The proactive approach to workboat safety offered by this system is crucial for minimizing risks and creating a safer working environment for all. Improve your workboat safety today. Contact TBS Safety and Nebofleet to learn more about our automated workboat safety solutions and how we can help you create a safer work environment and implement effective workboat safety strategies.

Featured Posts

-

Mental Health Care Reform Essential Steps For Progress

May 02, 2025

Mental Health Care Reform Essential Steps For Progress

May 02, 2025 -

Dalys Late Show Steals Victory For England In Six Nations Thriller Against France

May 02, 2025

Dalys Late Show Steals Victory For England In Six Nations Thriller Against France

May 02, 2025 -

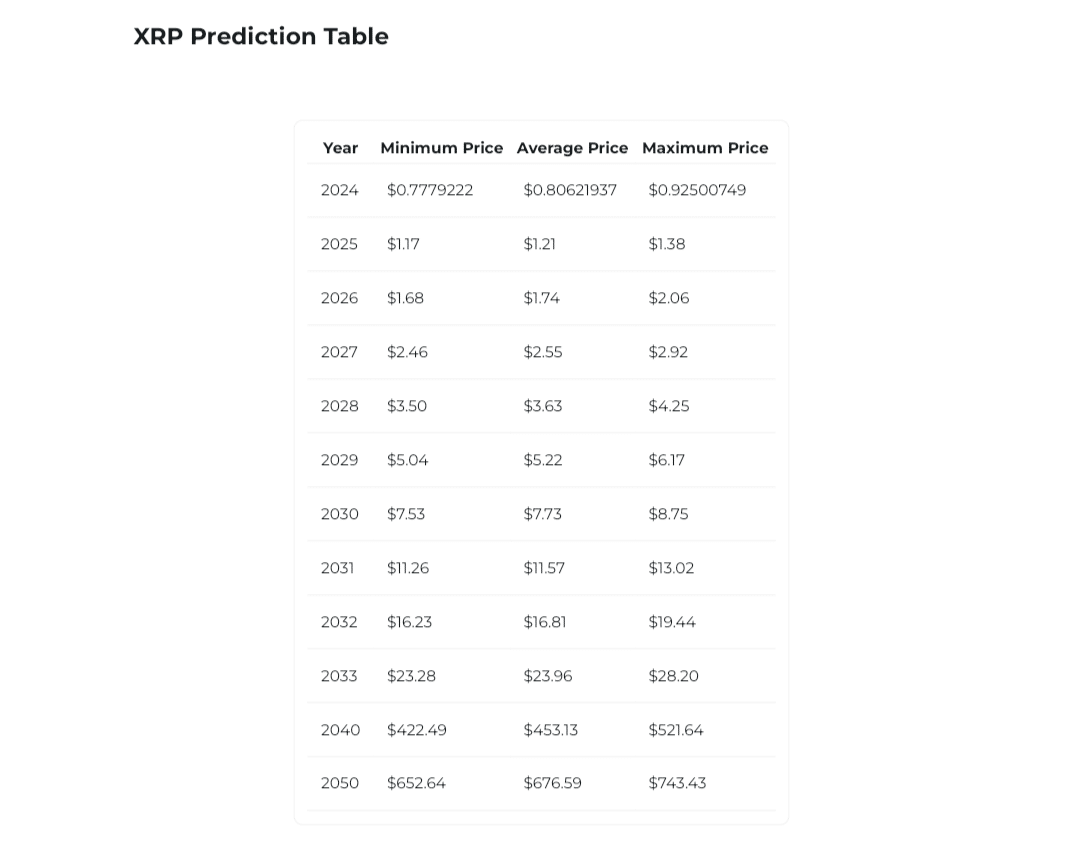

Xrp Cryptocurrency Everything You Need To Know

May 02, 2025

Xrp Cryptocurrency Everything You Need To Know

May 02, 2025 -

2 6 1

May 02, 2025

2 6 1

May 02, 2025 -

Winning Lotto Numbers For Saturday April 12th

May 02, 2025

Winning Lotto Numbers For Saturday April 12th

May 02, 2025