The Cricket Bat Maker: Skills Passed Down Through Generations

Table of Contents

The Selection of the Perfect Willow

The journey of creating a high-quality cricket bat begins long before the first cut of the wood. The selection of the finest English or Kashmir willow is paramount. The grain, density, and overall quality directly impact the performance and durability of the finished bat. This process demands years of experience and a keen eye for detail, a skill honed over generations of cricket bat makers. The choice between English willow and Kashmir willow, for example, often depends on the desired balance between power and weight.

- Careful inspection for knots, cracks, and imperfections: A seasoned cricket bat maker can instantly identify flaws that could compromise the bat's integrity. Even minor imperfections can significantly weaken the wood.

- Selecting wood with the right grain density for optimal power and durability: The density of the willow's grain directly affects the bat's "sweet spot" – the area where the impact generates the most power. A higher density generally means more power.

- Understanding the different grades of willow and their impact on bat performance: Willow is graded based on its quality and suitability for bat making. Higher grades signify superior strength and performance, reflecting in the final price.

- Sourcing willow from reputable suppliers with sustainable practices: Ethical sourcing is increasingly important. Reputable suppliers ensure the willow is harvested sustainably to protect the environment and maintain a consistent supply of high-quality wood for future generations of cricket bat makers.

The Time-Honored Techniques of Shaping and Carving

Traditional tools, passed down through generations, are essential to the shaping and carving of a handcrafted cricket bat. These aren't mass-produced items; each bat is a unique creation. This process demands immense skill and precision, transforming a raw piece of willow into the recognizable form of a cricket bat. Each cut is deliberate, ensuring perfect balance and optimal performance. The maker's expertise is evident in every curve and angle.

- Using specialized planes and chisels to shape the bat's profile: The shaping process meticulously follows traditional methods, using tools that allow for fine control and precision.

- Creating the unique "sweet spot" for maximum power: The sweet spot is the heart of the bat, and its precise location and size are crucial for maximizing power and minimizing vibrations upon impact.

- Ensuring the balance and weight distribution is perfect: A well-balanced bat enhances control and maneuverability, crucial factors for a cricketer's performance. Weight distribution is carefully considered during the shaping process.

- Hand-carving the toe and shoulder for aesthetics and functionality: The toe and shoulder of the bat aren't just aesthetic details; they play a role in its performance, influencing the bat's swing and balance.

The Art of Knocking-In and Finishing

The final stages of cricket bat making involve the crucial process of knocking-in the bat and applying the finishing touches. Knocking-in is a meticulous process of gently impacting the wood to harden it and prepare it for use. This process strengthens the willow and minimizes the risk of breakage during gameplay. Following this, specialized oils and finishes are applied to protect the wood and enhance its durability.

- The knocking-in process, ensuring strength and reducing the risk of breakage: This time-consuming process is vital for the longevity of the bat. It's a critical step performed by skilled cricket bat makers.

- Applying specialized oils to condition the willow: These oils nourish the wood, preventing cracking and enhancing its overall durability.

- Applying a final protective coating for durability and weather resistance: The final coating protects the bat from the elements, preserving its quality and extending its lifespan.

- Adding any personal touches or branding: Many cricket bat makers offer customization options, allowing players to personalize their bats with branding or unique designs.

The Legacy Continues: Passing Down the Craft

Many cricket bat makers are dedicated to preserving their craft, passing down their skills and knowledge to younger generations through apprenticeships and family traditions. This ensures the continuation of this rich heritage for years to come. However, the craft faces challenges in a modern world that often prioritizes speed and efficiency over traditional methods.

- The importance of mentorship and apprenticeships in training the next generation: Passing on the intricate skills and knowledge requires a dedication to mentorship and the willingness to share expertise.

- The role of family traditions in preserving the craft: Family businesses play a crucial role in the transmission of traditional knowledge and skills across generations.

- The challenges of maintaining traditional methods in a modern world: The increasing cost of materials and the pressure to compete in a global market often put pressure on traditional methods.

- The efforts to promote and preserve the legacy of cricket bat making: Initiatives to raise awareness and promote the value of handcrafted cricket bats are vital to the future of this unique craft.

Conclusion

The creation of a handcrafted cricket bat is a testament to skill, patience, and a deep respect for tradition. From selecting the finest willow to the final polish, the cricket bat maker's journey is a fascinating blend of artistry and craftsmanship. By supporting these artisans and appreciating the legacy they represent, we ensure that the art of cricket bat making continues to thrive. Discover the passion and dedication behind each handcrafted cricket bat and support the preservation of this cherished tradition. Invest in a truly unique and expertly crafted cricket bat today! Find your perfect handcrafted cricket bat from a skilled maker and experience the difference.

Featured Posts

-

Piastris Stunning Bahrain Gp Pole Position

May 23, 2025

Piastris Stunning Bahrain Gp Pole Position

May 23, 2025 -

New County Season Talking Points Familiar Faces And Trophy Battles

May 23, 2025

New County Season Talking Points Familiar Faces And Trophy Battles

May 23, 2025 -

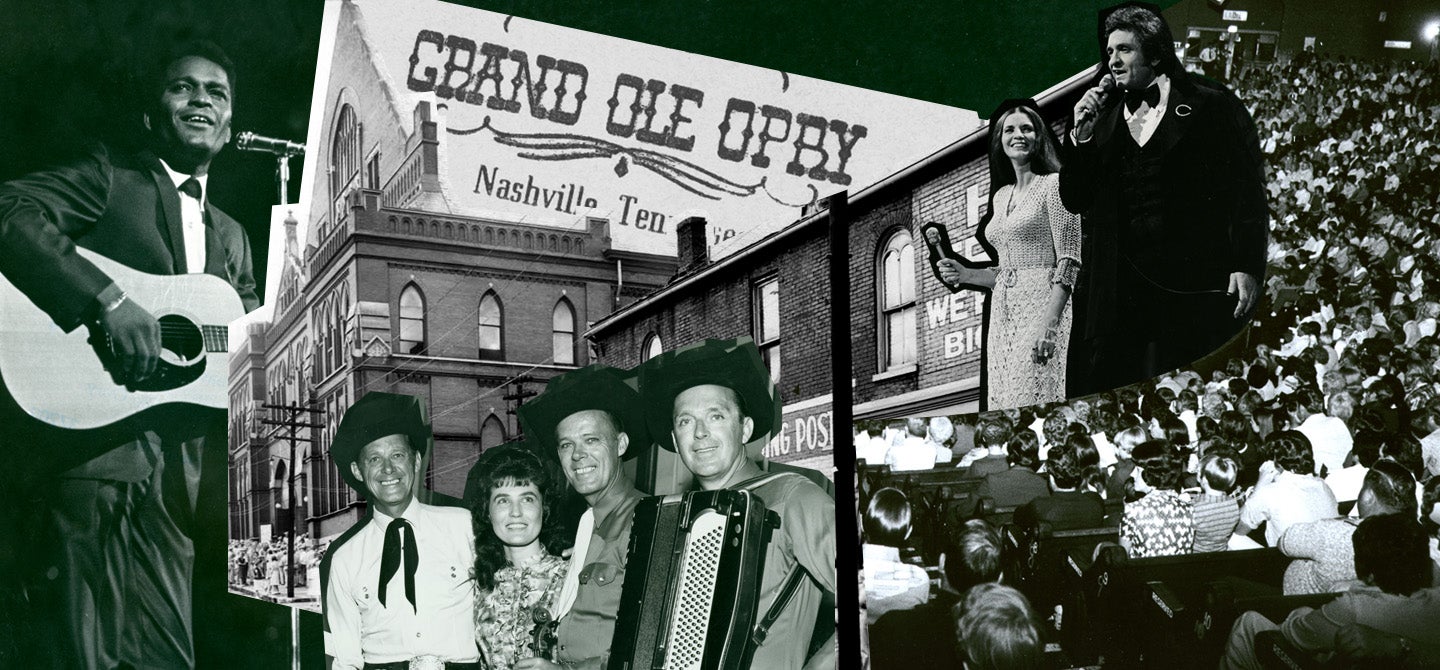

Royal Albert Hall To Host Grand Ole Oprys First International Broadcast

May 23, 2025

Royal Albert Hall To Host Grand Ole Oprys First International Broadcast

May 23, 2025 -

Whats Leaving Hulu This Month A Full List Of Departing Movies

May 23, 2025

Whats Leaving Hulu This Month A Full List Of Departing Movies

May 23, 2025 -

Netflix Unveils New Drama Sexy Dark Humor With Familiar Faces

May 23, 2025

Netflix Unveils New Drama Sexy Dark Humor With Familiar Faces

May 23, 2025

Latest Posts

-

Lmht Ela Tjrbt Snae Aflam Fy Brnamj Qmrt Ldem Almwahb

May 23, 2025

Lmht Ela Tjrbt Snae Aflam Fy Brnamj Qmrt Ldem Almwahb

May 23, 2025 -

Qmrt Nhw Synma Qtryt Ealmyt

May 23, 2025

Qmrt Nhw Synma Qtryt Ealmyt

May 23, 2025 -

Bsmat Qmrt Ela Snaet Alaflam Fy Qtr

May 23, 2025

Bsmat Qmrt Ela Snaet Alaflam Fy Qtr

May 23, 2025 -

Alastthmar Fy Almwahb Dwr Qmrt Fy Snaet Alaflam Alqtryt

May 23, 2025

Alastthmar Fy Almwahb Dwr Qmrt Fy Snaet Alaflam Alqtryt

May 23, 2025 -

Qmrt Qst Njah Fy Dem Almwahb Alsynmayyt Alqtryt

May 23, 2025

Qmrt Qst Njah Fy Dem Almwahb Alsynmayyt Alqtryt

May 23, 2025