The Future Of Automated Visual Inspection For Lyophilized Vials: Technological Solutions To Current Challenges

Table of Contents

Advanced Imaging Technologies for Lyophilized Vial Inspection

Effective automated visual inspection hinges on cutting-edge imaging technologies capable of detecting even the most subtle defects in lyophilized vials.

High-Resolution Imaging

High-resolution cameras, coupled with sophisticated lighting techniques, are fundamental to successful automated inspection. These systems excel at identifying cracks, particulate matter, and inconsistencies in fill levels.

- Machine vision systems: Employ advanced algorithms to analyze images and identify deviations from pre-defined quality standards. They offer high speed and accuracy for basic defect detection.

- Hyperspectral imaging: Captures images across a wide range of wavelengths, providing detailed spectral information that can be used to detect subtle variations in material composition and identify defects invisible to the naked eye or standard machine vision. This technology offers unparalleled sensitivity for detecting subtle variations in the lyophilized cake.

- Advantages include increased sensitivity, higher speed, and reduced human intervention compared to manual inspection.

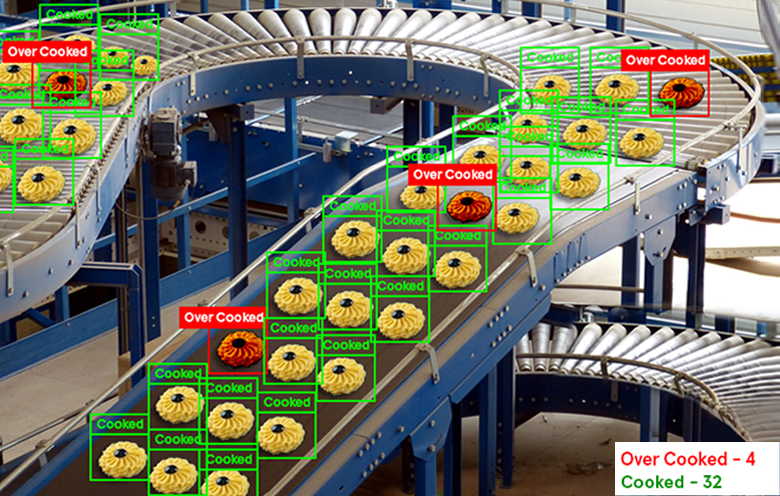

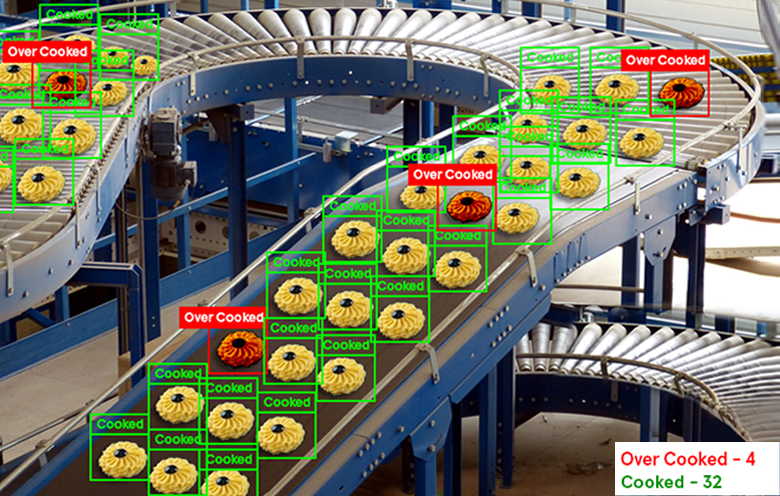

AI and Machine Learning in Defect Detection

Artificial intelligence (AI) and machine learning (ML) are revolutionizing automated visual inspection. AI algorithms can learn to identify defects with increasing accuracy over time, adapting to variations in vial appearance and product characteristics.

- Deep learning: Utilizes artificial neural networks with multiple layers to extract complex features from images and classify defects with high precision. This is particularly useful for identifying complex or irregular defects.

- Convolutional Neural Networks (CNNs): Specialized deep learning architectures designed for image analysis, excelling at identifying patterns and features indicative of defects. CNNs are highly effective in detecting subtle variations in cake structure and appearance.

- Benefits include a significant reduction in false positives, leading to improved throughput and minimizing unnecessary rejects, and continuous improvement in accuracy through ongoing learning.

3D Imaging and Advanced Analytics

Moving beyond 2D imaging, 3D technologies offer a comprehensive view of the vial and its contents. Techniques like structured light and laser triangulation capture detailed three-dimensional information, enabling the detection of defects that may be missed by 2D systems.

- Structured light: Projects a pattern of light onto the vial, capturing the deformation of the pattern to create a 3D model. This technique is excellent for assessing vial shape and detecting surface irregularities.

- Laser triangulation: Measures the distance to the vial's surface using a laser, creating a precise 3D point cloud. This method is highly accurate for determining fill levels and detecting variations in cake morphology.

- The integration of 3D data with AI-powered analysis further enhances the accuracy and reliability of defect detection. This approach allows for more sophisticated analysis, better handling of variations, and improved decision-making in the inspection process.

Overcoming Challenges in Automated Lyophilized Vial Inspection

Implementing automated visual inspection systems for lyophilized vials requires addressing several challenges.

Variability in Lyophilized Products

Lyophilized products exhibit inherent variability in terms of vial shape, fill level, and cake appearance. Automated systems must account for these variations to ensure consistent and reliable inspection results.

- Adaptive algorithms: AI-powered systems can be trained to adapt to variations in product characteristics, minimizing the impact of these variations on inspection accuracy.

- Calibration and standardization: Rigorous calibration and standardization procedures are essential to maintain consistent inspection results across different batches and production runs. This includes regular calibration checks on imaging equipment and image analysis software.

Data Management and Traceability

Effective data management and traceability are crucial for regulatory compliance. Automated systems must provide comprehensive data logging, reporting, and analysis capabilities.

- Data logging software: Records all inspection results, including images, measurements, and defect classifications. This comprehensive data record allows for detailed analysis and trend identification.

- Integration with MES: Integration with existing manufacturing execution systems (MES) enables seamless data flow and traceability throughout the entire manufacturing process.

System Validation and Qualification

Thorough validation and qualification of automated inspection systems are essential to ensure compliance with regulatory requirements (e.g., GMP).

- Validation protocols: Rigorous protocols must be followed to demonstrate the accuracy, reliability, and precision of the system. This includes assessing the system's ability to detect known defects and its false positive and false negative rates.

- Qualification procedures: Procedures for installation qualification (IQ), operational qualification (OQ), and performance qualification (PQ) ensure that the system operates as intended and meets regulatory standards.

The Economic Benefits of Automated Visual Inspection

The transition to automated visual inspection offers substantial economic advantages.

Reduced Labor Costs

Automating inspection significantly reduces reliance on manual labor, resulting in lower personnel costs and improved overall cost-effectiveness.

Improved Throughput and Efficiency

Automated systems significantly increase inspection speed, leading to higher production rates and faster turnaround times. This improved efficiency directly impacts productivity and profitability.

Enhanced Product Quality and Reduced Waste

Automated visual inspection leads to improved accuracy in defect detection, minimizing the risk of releasing defective products into the market and reducing product waste due to unnecessary rejects. This increased quality ensures patient safety and improves brand reputation.

Conclusion

Automated visual inspection systems are revolutionizing quality control for lyophilized vials. The combination of advanced imaging technologies, AI-powered analysis, and robust data management systems provides unparalleled accuracy, efficiency, and regulatory compliance. The resulting improvements in product quality, reduced labor costs, and enhanced throughput deliver significant economic benefits. Emerging trends, such as the increasing use of hyperspectral imaging and more sophisticated AI algorithms, promise further advancements in the field. Invest in the future of pharmaceutical quality control with advanced automated visual inspection for lyophilized vials. Contact us today to learn how our solutions can improve your efficiency and compliance.

Featured Posts

-

Mackenzie Mc Kee And Khesanio Hall Expecting A Child

May 11, 2025

Mackenzie Mc Kee And Khesanio Hall Expecting A Child

May 11, 2025 -

The 2024 Victory Day Parade Decoding Putins Message To The World

May 11, 2025

The 2024 Victory Day Parade Decoding Putins Message To The World

May 11, 2025 -

Saisonende Bundesliga Abstieg Fuer Bochum Und Kiel Leipzig Ohne Champions League

May 11, 2025

Saisonende Bundesliga Abstieg Fuer Bochum Und Kiel Leipzig Ohne Champions League

May 11, 2025 -

Understanding Payton Pritchards Nba Breakthrough

May 11, 2025

Understanding Payton Pritchards Nba Breakthrough

May 11, 2025 -

Nuits Saint Georges Candeloro Et Ladesou En Images Lors De La Vente Des Vins

May 11, 2025

Nuits Saint Georges Candeloro Et Ladesou En Images Lors De La Vente Des Vins

May 11, 2025