The Great Decoupling: Its Impact On Global Supply Chains

Table of Contents

Geopolitical Tensions and the Restructuring of Supply Chains

The rise of protectionism and the increasing frequency of trade wars are major drivers of the Great Decoupling. These geopolitical tensions are forcing companies to rethink their reliance on globally dispersed supply chains.

The Rise of Protectionism and Trade Wars:

Tariffs and trade disputes significantly disrupt global supply chain dynamics. The US-China trade war, for example, led to increased costs, disrupted production schedules, and prompted many companies to relocate manufacturing facilities to mitigate the impact of tariffs and trade uncertainty.

- Increased costs: Tariffs directly increase the price of imported goods, impacting profitability and competitiveness.

- Disrupted production: Trade disputes can lead to delays in the delivery of raw materials and components, halting production lines.

- Relocation of manufacturing facilities: Companies are increasingly relocating their production facilities to countries with more favorable trade relations or to diversify their sourcing.

Diversification Strategies to Reduce Geopolitical Risk:

To reduce their exposure to geopolitical risk, companies are adopting diversification strategies, moving away from reliance on single sourcing locations. Nearshoring (relocating production to nearby countries) and friend-shoring (relocating to countries with strong political and economic alliances) are becoming increasingly popular.

- Increased resilience: Diversification makes supply chains less vulnerable to disruptions caused by geopolitical events.

- Higher costs: Nearshoring and friend-shoring can lead to higher labor and transportation costs compared to utilizing low-cost manufacturing hubs.

- Logistical complexities: Managing a more geographically dispersed supply chain increases logistical complexity and requires sophisticated supply chain management systems.

Pandemic-Induced Vulnerabilities and Supply Chain Resilience

The COVID-19 pandemic exposed the fragility of overly concentrated and globalized supply chains, highlighting the need for greater resilience.

Exposing Weaknesses in Globalized Production:

The pandemic's impact on global supply chains was dramatic. Factory shutdowns in key manufacturing hubs, logistical bottlenecks at ports and airports, and widespread shortages of essential goods demonstrated the vulnerabilities of relying on just-in-time inventory management systems and highly concentrated production.

- Supply shortages: Disruptions in manufacturing and transportation led to acute shortages of various goods, ranging from medical equipment to consumer electronics.

- Increased lead times: Supply chain disruptions significantly increased lead times for many products, delaying deliveries and impacting businesses.

- Heightened consumer anxiety: Supply shortages and uncertainty contributed to heightened consumer anxiety and concerns about future availability of goods.

Investing in Supply Chain Resilience and Diversification:

In the wake of the pandemic, companies are prioritizing investments in supply chain resilience and diversification. This involves utilizing technology, improving inventory management practices, and conducting comprehensive risk assessments.

- Automation: Automating various aspects of the supply chain, from warehousing to transportation, can increase efficiency and reduce reliance on manual labor.

- Digitalization: Implementing digital supply chain management systems provides greater visibility and control over the entire supply chain.

- Improved forecasting: Utilizing advanced analytics and forecasting techniques improves inventory management and reduces the risk of stockouts.

- Inventory optimization: Holding strategic safety stock levels helps mitigate the risk of disruptions, even though this involves increased holding costs.

The Push for Regionalization and Regional Value Chains

The Great Decoupling is accelerating the trend towards regionalization, with countries focusing on building regional value chains and strengthening regional trade relationships.

The Rise of Regional Trade Agreements:

Regional trade agreements (RTAs) are playing a crucial role in reshaping global supply chains. Agreements like the EU, USMCA (United States-Mexico-Canada Agreement), and RCEP (Regional Comprehensive Economic Partnership) are reducing trade barriers and encouraging localized production within specific regions.

- Reduced trade barriers: RTAs eliminate or reduce tariffs and other trade barriers, facilitating trade and investment within the region.

- Increased regional cooperation: RTAs promote greater regional cooperation on issues related to trade, investment, and regulation.

- Localized production: RTAs incentivize companies to establish production facilities within the region, reducing dependence on distant suppliers.

Challenges and Opportunities of Regionalized Supply Chains:

While regionalization offers significant benefits, it also presents challenges. Smaller market size within a region compared to global markets and potential increased production costs due to limited access to specialized inputs are important considerations.

- Smaller markets: Regionalized supply chains may limit access to larger markets compared to globally integrated systems.

- Potential for increased production costs: Regional production may not always be the most cost-effective option, especially for specialized components or goods with economies of scale.

- Limited access to specialized inputs: Regionalized supply chains may lack access to the specialized inputs and expertise available in a globally integrated system.

Conclusion

The Great Decoupling represents a fundamental shift in global economic geography. The intertwined impacts of geopolitical instability, pandemic vulnerabilities, and the push for regionalization are forcing businesses to re-evaluate their supply chain strategies. Moving forward, building resilient, diversified, and adaptable supply chains is crucial for navigating the complexities of this new era. Understanding the implications of the Great Decoupling is not merely an academic exercise; it is essential for the survival and prosperity of businesses in an increasingly fragmented global landscape. Learn more about adapting your strategies to the complexities of the Great Decoupling and build a more resilient future for your business. Develop a robust decoupling strategy today.

Featured Posts

-

Londontsy Protiv Parizhan Istoriya Matchey Arsenal Ps Zh V Evrokubkakh

May 08, 2025

Londontsy Protiv Parizhan Istoriya Matchey Arsenal Ps Zh V Evrokubkakh

May 08, 2025 -

Krypto Joins Superman A Whistle Stop Adventure Next Week

May 08, 2025

Krypto Joins Superman A Whistle Stop Adventure Next Week

May 08, 2025 -

Ethereum Price Forecast Factors Influencing Future Value

May 08, 2025

Ethereum Price Forecast Factors Influencing Future Value

May 08, 2025 -

Van Drivers Road Rage Leads To Motorcycle Collision Cnn

May 08, 2025

Van Drivers Road Rage Leads To Motorcycle Collision Cnn

May 08, 2025 -

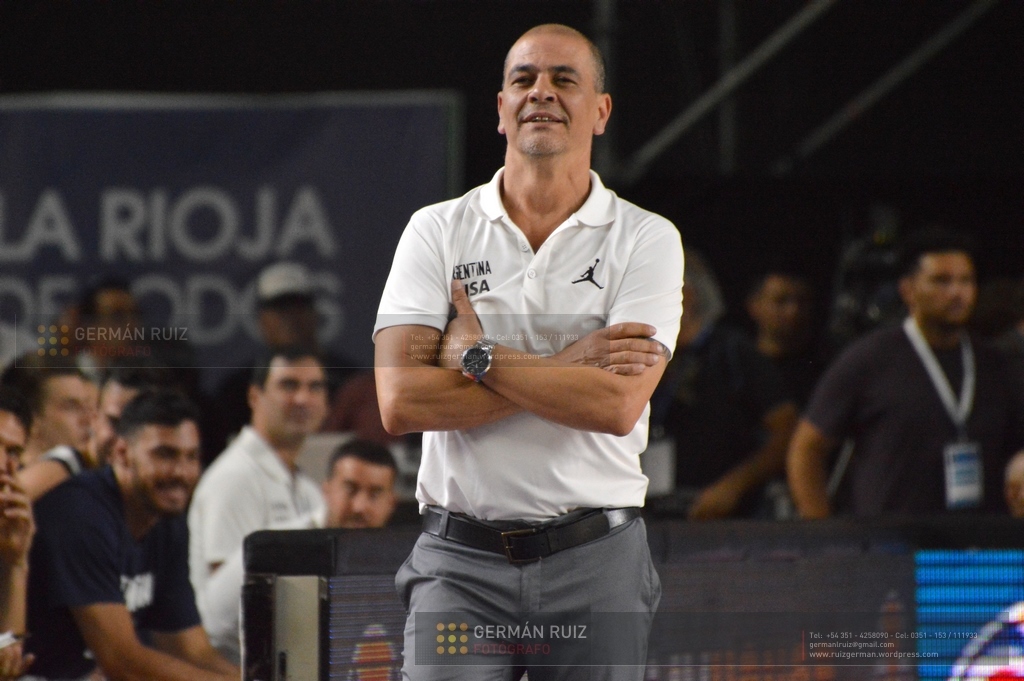

Flamengo Confirma A Sergio Hernandez Como Nuevo Tecnico

May 08, 2025

Flamengo Confirma A Sergio Hernandez Como Nuevo Tecnico

May 08, 2025