The Great Decoupling: Reshaping Global Supply Chains And Trade

Table of Contents

Geopolitical Tensions and the Rise of Protectionism

Political instability and escalating trade wars are primary drivers of the Great Decoupling. The US-China trade war, for example, highlighted the fragility of relying on single-source manufacturing and the vulnerability of globally integrated supply chains. This geopolitical uncertainty is pushing companies to diversify their sourcing and manufacturing locations, seeking greater resilience and reduced dependence on any single nation.

- Increased tariffs and trade barriers: The imposition of tariffs and other trade barriers creates significant costs and complexities for businesses reliant on global supply chains, incentivizing a shift towards regionalization.

- Sanctions and geopolitical risks impacting supply chain reliability: Geopolitical instability, sanctions, and unexpected events in various regions create significant disruptions and uncertainty, forcing companies to reassess their risk profiles and seek alternative sourcing options.

- The search for "friend-shoring" and "near-shoring" strategies: Many businesses are actively pursuing "friend-shoring," establishing partnerships and sourcing from countries with aligned political and economic interests, and "near-shoring," relocating production to geographically closer locations to mitigate risks and reduce transit times.

- Growing importance of regional trade agreements: The rise of regional trade agreements, such as the CPTPP (Comprehensive and Progressive Agreement for Trans-Pacific Partnership), reflects a growing trend towards regional economic integration and reduced reliance on globalized supply chains. This fosters closer economic ties and reduces the impact of broader geopolitical tensions.

The Impact of the COVID-19 Pandemic on Global Supply Chains

The COVID-19 pandemic dramatically exposed the vulnerabilities inherent in globally integrated, just-in-time manufacturing systems. Lockdowns, port congestion, and transportation disruptions led to widespread supply chain bottlenecks and shortages, highlighting the risks associated with over-reliance on complex, geographically dispersed networks.

- Supply chain bottlenecks and disruptions: The pandemic caused widespread disruptions, impacting everything from the availability of raw materials to the timely delivery of finished goods. This led to significant economic losses and highlighted the need for greater supply chain resilience.

- Increased reliance on just-in-time manufacturing exposed as risky: The just-in-time manufacturing model, which aims to minimize inventory by receiving materials only as needed, proved vulnerable to disruptions. The pandemic demonstrated the need for greater inventory buffers and more diversified sourcing strategies.

- Reshoring and regionalization efforts accelerated by pandemic vulnerabilities: The pandemic significantly accelerated the trend towards reshoring (bringing manufacturing back to the home country) and regionalization, as companies sought to reduce their dependence on distant suppliers and mitigate future risks.

- Increased focus on supply chain resilience and risk management: The pandemic spurred a renewed focus on building more resilient supply chains, incorporating robust risk management strategies, and diversifying sourcing to avoid single points of failure.

Technological Advancements and Automation's Role

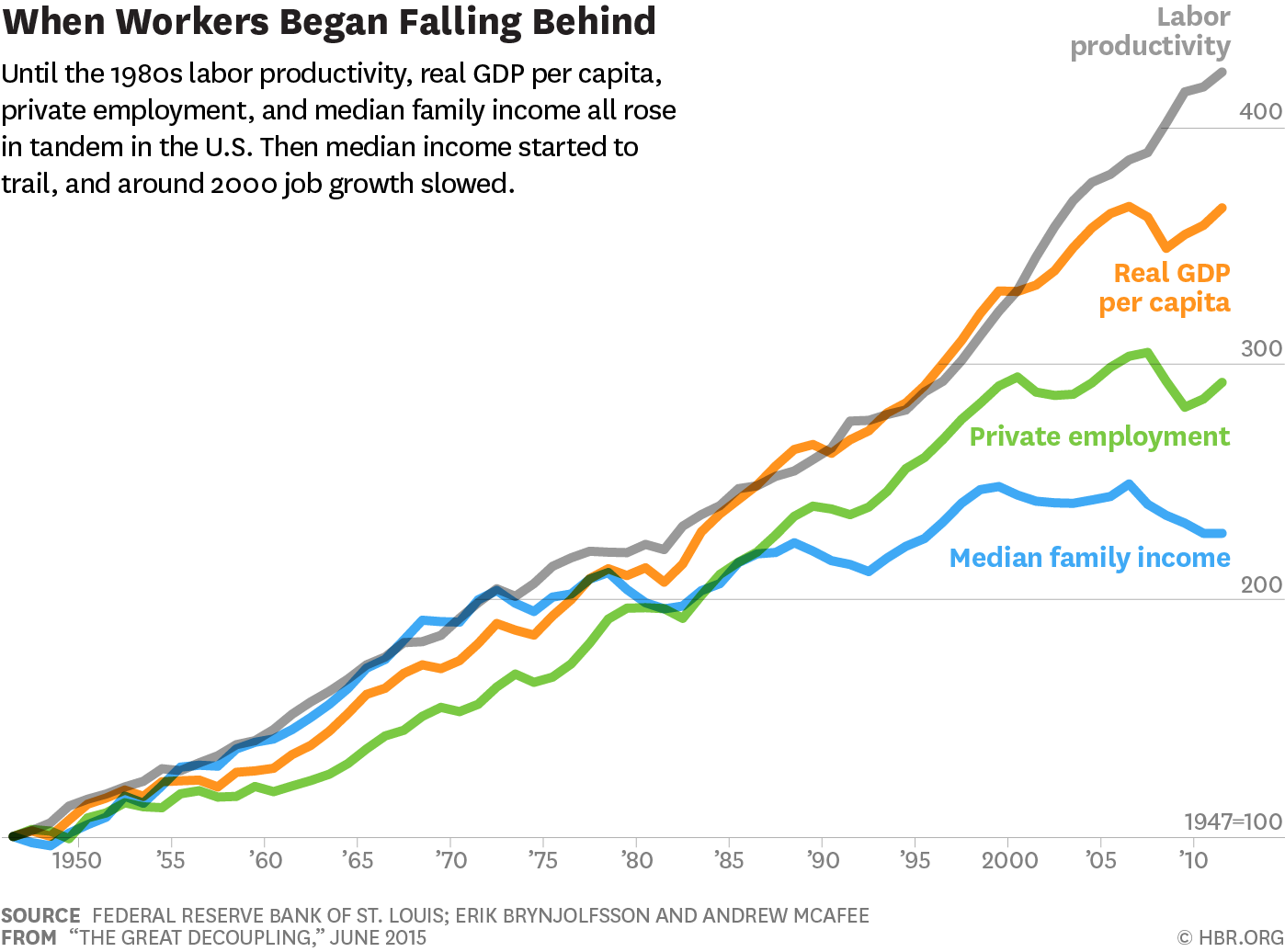

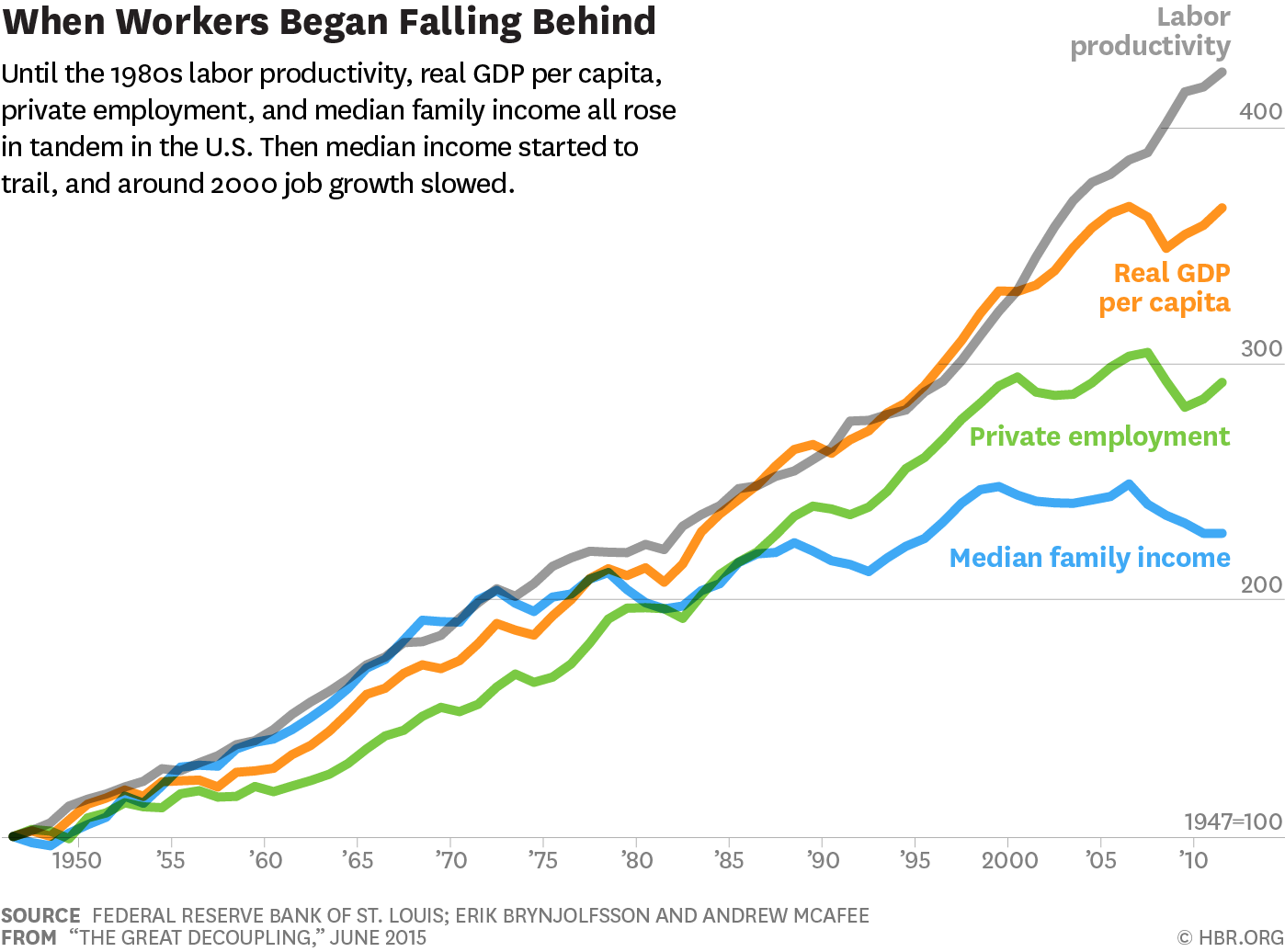

Technological advancements are playing a pivotal role in the Great Decoupling. Automation and artificial intelligence (AI) are reducing the reliance on low-cost labor, making it economically viable to shift manufacturing closer to consumer markets.

- Automation reducing reliance on low-cost labor: Automation technologies, including robotics and advanced manufacturing processes, are decreasing the cost advantage of low-wage countries, allowing companies to consider onshoring or near-shoring options.

- Increased capacity for onshoring and regional production: Advances in automation are making it feasible to manufacture goods efficiently in higher-cost regions, reducing the pressure to locate production solely in low-wage countries.

- The rise of digital supply chains and improved transparency: Digital technologies are enabling the development of more transparent and efficient supply chains, providing greater visibility into every stage of the production process and facilitating better risk management.

- Potential for increased efficiency and reduced transportation costs in regionalized systems: Regionalized supply chains can potentially lead to increased efficiency and reduced transportation costs, as goods travel shorter distances.

Sustainability Concerns and Ethical Sourcing

Growing consumer awareness of environmental and social issues is driving a significant shift towards sustainable and ethical sourcing practices. This is influencing supply chain restructuring, with businesses facing increasing pressure to minimize their carbon footprint and ensure fair labor practices throughout their supply chains.

- Consumer demand for ethically and sustainably produced goods: Consumers are increasingly demanding products that are ethically sourced and produced sustainably, putting pressure on companies to adopt responsible practices.

- Environmental regulations impacting supply chain choices: Stringent environmental regulations are impacting supply chain choices, pushing businesses to prioritize sustainability and minimize their environmental impact.

- Focus on reducing carbon footprint through localized production: Localized production can contribute to reducing the carbon footprint associated with transportation, making it an attractive option for businesses committed to sustainability.

- Increased transparency and traceability in supply chains: Consumers and regulators are demanding greater transparency and traceability in supply chains, enabling better monitoring of ethical and environmental practices.

Conclusion

The Great Decoupling represents a fundamental shift in global trade and supply chain management. Geopolitical tensions, the COVID-19 pandemic, technological advancements, and ethical concerns are all converging to reshape the global economic landscape. Businesses must adapt by diversifying their sourcing, investing in resilient supply chains, and embracing new technologies. Ignoring the implications of this Great Decoupling could lead to significant competitive disadvantages. To thrive in this new era, companies must proactively strategize and implement effective solutions to navigate the complexities of a decoupling global economy and embrace the new realities of supply chain management. Understanding and adapting to the Great Decoupling is no longer optional; it is essential for long-term success. Successfully navigating the challenges of the Great Decoupling requires a proactive and strategic approach to supply chain management.

Featured Posts

-

Zaderzhki Reysov V Aeroportu Permi Iz Za Silnogo Snegopada

May 09, 2025

Zaderzhki Reysov V Aeroportu Permi Iz Za Silnogo Snegopada

May 09, 2025 -

National 2 Defaite De Dijon Face A Concarneau 0 1 04 04 2024

May 09, 2025

National 2 Defaite De Dijon Face A Concarneau 0 1 04 04 2024

May 09, 2025 -

100 Days Of Trump How Did It Affect Elon Musks Net Worth

May 09, 2025

100 Days Of Trump How Did It Affect Elon Musks Net Worth

May 09, 2025 -

2025 Presidential Politics A Retrospective On Day 109 Of The Trump Administration

May 09, 2025

2025 Presidential Politics A Retrospective On Day 109 Of The Trump Administration

May 09, 2025 -

Tesla Stock Decline Impacts Elon Musks Net Worth Below 300 Billion For The First Time Since November

May 09, 2025

Tesla Stock Decline Impacts Elon Musks Net Worth Below 300 Billion For The First Time Since November

May 09, 2025