These Electric Motors: Reducing Global Reliance On China

Table of Contents

The Current State of Electric Motor Production and China's Dominance

China's dominance in the electric motor market is undeniable. This control extends across the entire value chain, from the mining of raw materials to the final assembly of sophisticated motors. Understanding this dominance is crucial to addressing the vulnerabilities it creates.

China's Market Share and its Impact

China holds a commanding share of the global electric motor market, estimated to be over 70% for certain types of motors. This high market share has several significant implications:

- Price Volatility: China's control over production leads to price fluctuations that can disrupt global markets and impact the affordability of electric vehicles and renewable energy technologies.

- Supply Chain Bottlenecks: The concentration of manufacturing in China creates a single point of failure. Disruptions in China, whether due to natural disasters, political instability, or trade disputes, can severely impact global supply chains.

- Component Dependence: Many key electric motor components, including rare earth magnets and specific electronic components, are heavily sourced from China, increasing dependence and vulnerability. For example, the production of neodymium magnets, critical for high-performance electric motors, is concentrated in China.

Geopolitical Risks Associated with Over-Reliance

The heavy reliance on China for electric motors poses significant geopolitical risks:

- Trade Wars and Sanctions: Trade disputes or sanctions imposed on China could drastically limit the supply of electric motors, impacting industries worldwide.

- Political Instability: Internal political instability within China could disrupt production and lead to global shortages.

- National Security Concerns: The dependence on a single nation for such a critical technology raises concerns about national security, particularly for nations heavily reliant on electric motors for defense or critical infrastructure.

Strategies for Diversifying Electric Motor Production

Diversifying electric motor production is essential for mitigating the risks associated with over-reliance on China. This requires a multi-pronged approach involving domestic investment, international collaboration, and technological innovation.

Investing in Domestic Manufacturing

Boosting domestic electric motor production requires significant investment:

- Government Incentives: Governments can incentivize domestic manufacturing through tax breaks, grants, and subsidies to attract investment in electric motor factories.

- Research and Development Funding: Increased funding for research and development is crucial to fostering innovation and developing more efficient and cost-effective electric motor designs.

- Workforce Training Programs: Investing in skilled labor is essential. Training programs can equip workers with the skills needed for electric motor manufacturing, maintenance, and repair.

Fostering International Collaboration

International partnerships are vital for sharing technology and expertise:

- Technology Transfer Agreements: Collaboration agreements between nations can facilitate the transfer of technology and knowledge, helping to build capacity in other regions.

- Joint Research and Development: Shared research initiatives can accelerate innovation and development of new electric motor technologies.

- Supply Chain Diversification: International partnerships can help diversify the supply chain, reducing reliance on a single source for critical components.

Supporting the Development of Alternative Technologies

Exploring alternative technologies can further reduce reliance on China:

- New Motor Designs: Research into alternative motor designs, such as axial flux motors or switched reluctance motors, can reduce dependence on specific materials or manufacturing processes concentrated in China.

- Sustainable Manufacturing: Adopting sustainable manufacturing practices can reduce the environmental impact of electric motor production and promote responsible sourcing of materials.

- New Materials Research: Exploring alternative materials that can replace rare earth magnets or other components heavily reliant on Chinese sources is crucial for long-term independence.

The Role of Sustainable and Ethical Sourcing in Reducing Reliance on China

Ethical and sustainable practices are paramount in reducing dependence on China.

Prioritizing Ethical and Sustainable Supply Chains

Ethical sourcing ensures fair labor practices and environmental sustainability:

- Fair Trade Practices: Prioritizing suppliers committed to fair wages, safe working conditions, and environmental protection is crucial.

- Sustainable Manufacturing Initiatives: Implementing sustainable manufacturing processes, reducing waste and emissions, and promoting responsible disposal of components.

- Environmental Impact Assessment: Conducting thorough environmental impact assessments throughout the supply chain to identify and minimize negative consequences.

Promoting Transparency and Traceability

Greater transparency and traceability in the supply chain are crucial for risk mitigation:

- Blockchain Technology: Utilizing blockchain technology to track components from origin to final product enhances transparency and accountability.

- Industry Standards for Transparency: Developing and implementing industry standards for transparency and traceability can increase trust and reduce risks.

- Supply Chain Mapping: Detailed mapping of the entire supply chain allows for proactive identification of vulnerabilities and potential disruptions.

Conclusion

Reducing global reliance on China for electric motors is a critical strategic imperative. China's dominance presents significant geopolitical and economic risks. Diversifying production through domestic investment, international collaboration, and technological innovation is essential for creating a more resilient and secure global ecosystem for these electric motors. By prioritizing ethical and sustainable sourcing and promoting transparency throughout the supply chain, we can mitigate risks and build a more sustainable future for the electric motor industry. We urge readers to learn more about these critical issues, support policies that promote domestic manufacturing and international collaboration, and demand greater transparency and ethical sourcing in the supply chain. Only through concerted effort can we achieve true independence in the production of these electric motors.

Featured Posts

-

The La Palisades Fire A List Of Celebrities Who Lost Their Properties

May 05, 2025

The La Palisades Fire A List Of Celebrities Who Lost Their Properties

May 05, 2025 -

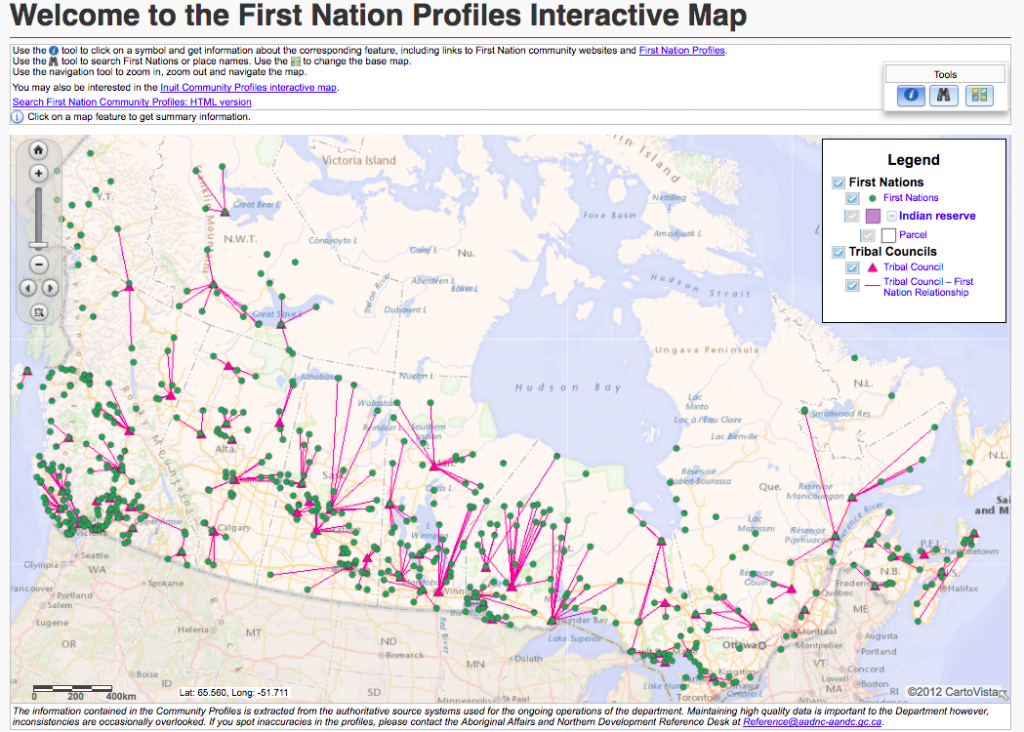

New Business Hotspots Across The Nation An Interactive Map

May 05, 2025

New Business Hotspots Across The Nation An Interactive Map

May 05, 2025 -

Cusmas Fate Hangs In The Balance Carneys Crucial Talks With Trump

May 05, 2025

Cusmas Fate Hangs In The Balance Carneys Crucial Talks With Trump

May 05, 2025 -

Inside The Wildest Crypto Party A Two Day Account

May 05, 2025

Inside The Wildest Crypto Party A Two Day Account

May 05, 2025 -

Blue Origin Postpones Launch Vehicle Subsystem Problem Delays Mission

May 05, 2025

Blue Origin Postpones Launch Vehicle Subsystem Problem Delays Mission

May 05, 2025

Latest Posts

-

Important Updates To The Ufc 314 Pay Per View Lineup

May 05, 2025

Important Updates To The Ufc 314 Pay Per View Lineup

May 05, 2025 -

Ufc 314 Changes To The Fight Card Announced

May 05, 2025

Ufc 314 Changes To The Fight Card Announced

May 05, 2025 -

Revised Fight Order For Ufc 314 Pay Per View Event

May 05, 2025

Revised Fight Order For Ufc 314 Pay Per View Event

May 05, 2025 -

Inside Paddy Pimbletts Private Yacht Party After Triumphant Ufc 314 Bout

May 05, 2025

Inside Paddy Pimbletts Private Yacht Party After Triumphant Ufc 314 Bout

May 05, 2025 -

Ufc 314 Paddy Pimbletts Exclusive Yacht Party After Dominant Win

May 05, 2025

Ufc 314 Paddy Pimbletts Exclusive Yacht Party After Dominant Win

May 05, 2025