US Electric Motor Manufacturing: A Strategy For Reducing China Dependence

Table of Contents

Assessing the Current State of US Electric Motor Manufacturing

Current Dependence on China

The US currently exhibits a significant dependence on China for electric motor imports. Chinese manufacturers hold a substantial market share, supplying a large portion of electric motors used across numerous sectors. This dependence creates vulnerabilities in the face of geopolitical instability or disruptions in the global supply chain.

- Specific statistics: While precise figures fluctuate, estimates suggest that a considerable percentage (quantify with data if available) of electric motors and crucial components used in the US originate from China. This includes a high proportion of smaller, specialized motors critical for various applications.

- Examples: Many electric vehicles (EVs) rely on Chinese-sourced components within their motor systems. Similarly, significant portions of industrial machinery in the US utilize motors and parts imported from China.

- Keywords: China electric motor imports, US electric motor imports, supply chain vulnerabilities, electric motor components.

Identifying Gaps in Domestic Production

The US electric motor manufacturing sector faces several challenges hindering its ability to compete effectively with China. These shortcomings need immediate attention to bolster domestic production.

- Lack of production capacity: Existing US facilities often lack the scale to meet the burgeoning demand for electric motors, particularly in high-growth sectors like electric vehicles and renewable energy.

- Technological gaps: China has made significant investments in advanced manufacturing technologies, resulting in higher production efficiency and lower costs. The US needs to close this technological gap through targeted R&D.

- Skilled labor shortages: A shortage of skilled workers with expertise in electric motor design, manufacturing, and maintenance hinders the expansion of domestic production capabilities.

- Regulatory hurdles: Complex regulations and bureaucratic processes can slow down the establishment and expansion of new manufacturing facilities in the US.

- Keywords: manufacturing capacity, technological innovation, skilled workforce, regulatory environment, electric motor technology.

Strategies for Boosting Domestic Electric Motor Production

Government Incentives and Policies

Government intervention is crucial in stimulating the growth of US electric motor manufacturing. Strategic policies and financial incentives can create a more favorable environment for domestic production.

- Tax incentives: Offering tax breaks and credits to companies investing in US-based electric motor manufacturing facilities can significantly reduce production costs.

- Grants for research and development: Funding research and development initiatives focused on improving electric motor design, manufacturing processes, and materials can accelerate technological advancements.

- Investment in infrastructure: Improving infrastructure, including transportation networks and access to reliable energy sources, is vital for supporting manufacturing growth.

- Protectionist trade policies: Carefully considered trade policies, such as targeted tariffs, can help level the playing field and protect domestic manufacturers from unfair competition.

- Keywords: government subsidies, tax credits, research grants, infrastructure investment, trade policy, electric motor manufacturing incentives.

Technological Innovation and R&D Investment

Investing in advanced manufacturing technologies and R&D is paramount for enhancing the competitiveness of US electric motor manufacturing.

- Automation: Implementing automation and robotics in manufacturing processes can significantly improve efficiency, reduce labor costs, and increase output.

- AI-driven manufacturing: Utilizing artificial intelligence in predictive maintenance and quality control can minimize downtime and optimize production.

- Next-generation designs: Developing and deploying more efficient, cost-effective, and sustainable electric motor designs is essential for staying ahead of the competition. This includes exploring new materials and manufacturing techniques.

- Keywords: advanced manufacturing, automation, artificial intelligence, R&D investment, electric motor technology, sustainable manufacturing.

Workforce Development and Training

A skilled and adequately trained workforce is critical for the success of the US electric motor industry.

- Vocational training programs: Investing in vocational training programs that provide specialized skills in electric motor design, manufacturing, and maintenance is crucial.

- Industry-education partnerships: Collaborations between educational institutions and industry players can ensure that training programs meet the specific needs of the sector.

- Talent acquisition and retention: Strategies to attract and retain skilled workers, such as competitive salaries and benefits packages, are essential for maintaining a strong workforce.

- Keywords: skilled labor, workforce training, vocational education, talent acquisition, electric motor skills gap.

Strengthening Supply Chain Resilience

Diversifying supply chains and reducing reliance on single-source suppliers is critical for mitigating risks and ensuring long-term stability.

- Domestic suppliers: Prioritizing partnerships with domestic suppliers for critical components and materials strengthens the resilience of the US supply chain.

- Strategic alliances: Establishing strategic alliances with reliable suppliers in other countries can diversify sourcing and mitigate risks associated with over-reliance on a single nation.

- Reshoring and nearshoring: Actively exploring opportunities to bring manufacturing back to the US (reshoring) or relocate it to nearby countries (nearshoring) can shorten supply chains and enhance resilience.

- Keywords: supply chain diversification, reshoring, nearshoring, supplier partnerships, supply chain resilience, domestic sourcing.

Overcoming Challenges and Barriers to Growth

Cost Competitiveness

Competing with the lower manufacturing costs in China presents a significant challenge. Strategies are needed to bridge this cost gap.

- Efficiency improvements: Implementing lean manufacturing principles and other efficiency-enhancing measures can reduce production costs.

- Automation to reduce labor costs: Increased automation can offset the higher labor costs in the US compared to China.

- Economies of scale: Achieving economies of scale through increased production volume can lower the unit cost of manufacturing.

- Keywords: manufacturing costs, cost competitiveness, automation efficiency, lean manufacturing.

Environmental Regulations

Balancing environmental sustainability with economic competitiveness requires careful consideration.

- Sustainable manufacturing practices: Adopting environmentally friendly manufacturing processes can both reduce the environmental impact and enhance the industry's image.

- Green technology: Investing in green technologies and sustainable materials can improve the environmental profile of electric motor manufacturing.

- Keywords: environmental regulations, sustainable manufacturing, green technology, eco-friendly manufacturing.

Conclusion

Reducing US dependence on China for electric motor manufacturing demands a multifaceted approach. This involves strategic government investment in R&D, robust workforce development programs, and a concentrated focus on establishing resilient and diversified supply chains. By proactively addressing the challenges and embracing technological innovation, the US can successfully revitalize its electric motor manufacturing sector, securing its future in this crucial industry. The future of US electric motor manufacturing hinges on the proactive implementation of these strategies to achieve genuine independence and global competitiveness. Take action now and support policies that foster domestic electric motor production and strengthen US electric motor manufacturing.

Featured Posts

-

Blockchain Analysis Leader Chainalysis Integrates Ai Startup Alterya

May 04, 2025

Blockchain Analysis Leader Chainalysis Integrates Ai Startup Alterya

May 04, 2025 -

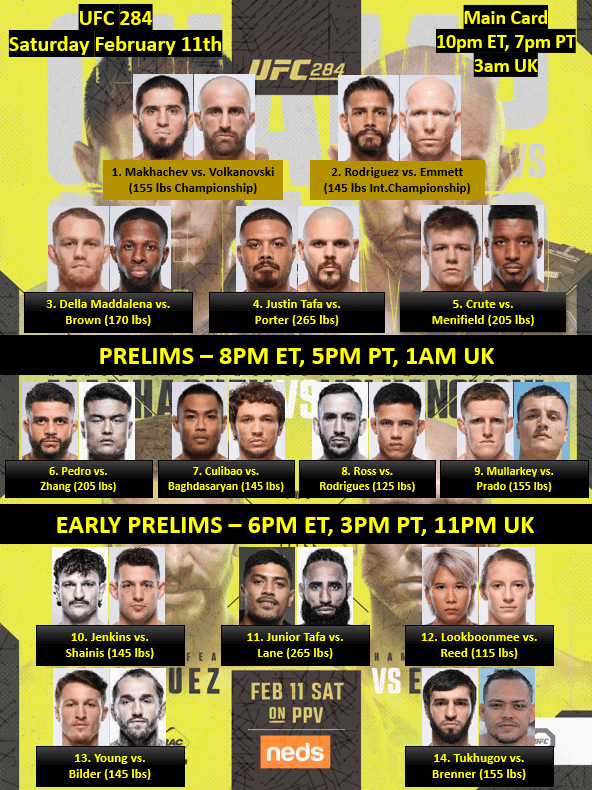

Official Ufc 314 Bout Order Main Card And Preliminary Fights Announced

May 04, 2025

Official Ufc 314 Bout Order Main Card And Preliminary Fights Announced

May 04, 2025 -

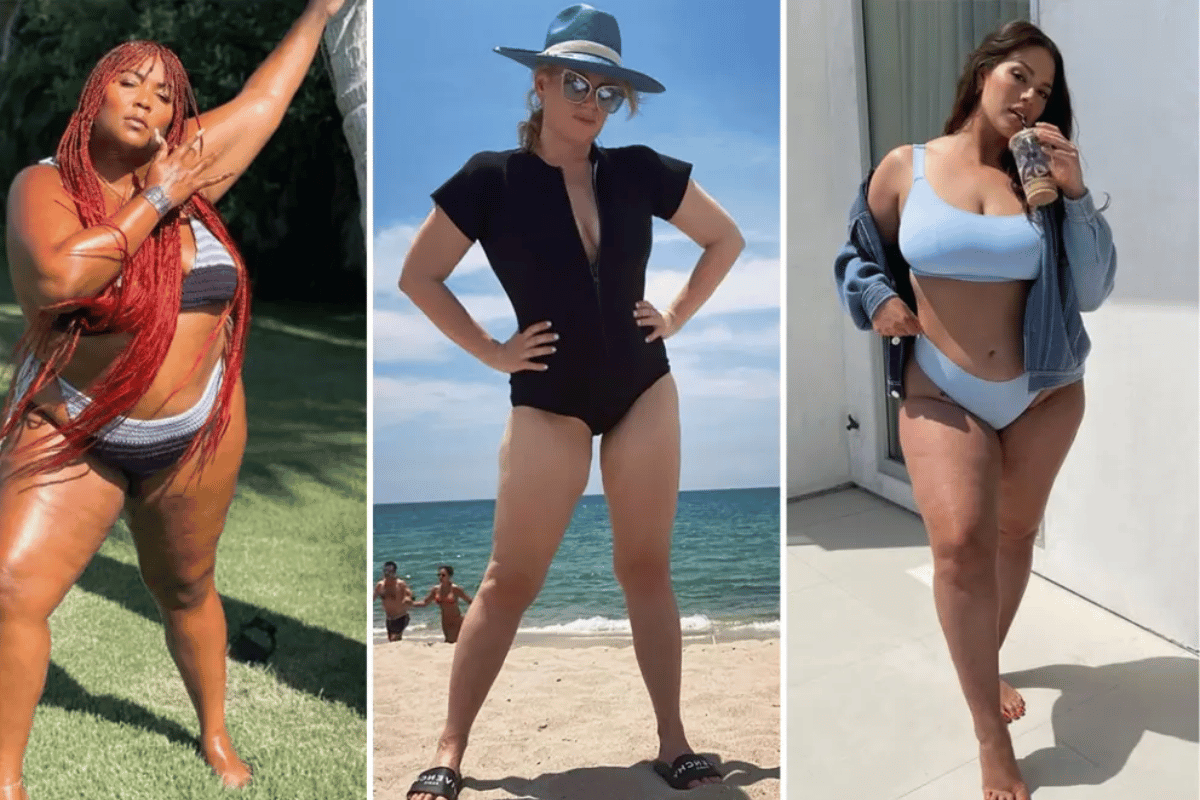

Lizzos Weight Loss Journey Slimmer Figure Energetic Dance

May 04, 2025

Lizzos Weight Loss Journey Slimmer Figure Energetic Dance

May 04, 2025 -

Spring Snowfall Forecast 1 2 Inches For Parts Of Nyc Suburbs

May 04, 2025

Spring Snowfall Forecast 1 2 Inches For Parts Of Nyc Suburbs

May 04, 2025 -

Oscars 2024 Lizzos Stunning Weight Loss Transformation

May 04, 2025

Oscars 2024 Lizzos Stunning Weight Loss Transformation

May 04, 2025

Latest Posts

-

Betting On Ufc 314 Understanding The Opening Odds

May 04, 2025

Betting On Ufc 314 Understanding The Opening Odds

May 04, 2025 -

Ufc 314 Fight Card A Deep Dive Into The Initial Betting Lines

May 04, 2025

Ufc 314 Fight Card A Deep Dive Into The Initial Betting Lines

May 04, 2025 -

Analyzing Ufc 314 Opening Betting Odds A Fighter By Fighter Look

May 04, 2025

Analyzing Ufc 314 Opening Betting Odds A Fighter By Fighter Look

May 04, 2025 -

Ufc 314 Early Betting Odds And Potential Upsets

May 04, 2025

Ufc 314 Early Betting Odds And Potential Upsets

May 04, 2025 -

Tri State Area Snow Forecast Timing And Accumulation

May 04, 2025

Tri State Area Snow Forecast Timing And Accumulation

May 04, 2025