AI In Process Safety: New Patent Offers Innovative Hazard Reduction

Table of Contents

The Patent's Core Technology

This innovative patent utilizes cutting-edge AI to significantly enhance process safety measures. Its core functionality revolves around three key technological pillars: AI-powered predictive maintenance, real-time anomaly detection, and enhanced risk assessment.

AI-Powered Predictive Maintenance

The patent focuses on using sophisticated machine learning algorithms to predict equipment failures and potential hazards before they occur. This proactive approach, a key aspect of process safety AI, significantly reduces the likelihood of accidents and costly downtime.

- Analysis of sensor data from various sources: The system ingests data streams from multiple sensors monitoring temperature, pressure, vibration, flow rates, and other critical parameters.

- Identification of patterns indicative of potential failures: Advanced machine learning models analyze these data streams, identifying subtle patterns and anomalies that might indicate impending equipment failure or process deviations. These models are trained on vast datasets of historical operational data, constantly learning and improving their predictive accuracy.

- Prioritization of maintenance tasks based on risk assessment: The system prioritizes maintenance tasks based on the predicted risk level, ensuring that critical issues are addressed promptly, minimizing potential disruptions and hazards.

- Integration with existing plant control systems: Seamless integration with existing plant control systems allows for automated scheduling of maintenance tasks and alerts to relevant personnel, streamlining the entire process.

Real-time Anomaly Detection

AI algorithms continuously monitor process parameters in real-time, identifying anomalies and deviations from normal operating conditions. This real-time anomaly detection is crucial for preventing the escalation of hazardous situations.

- Early warning systems for potential hazards: The system acts as an early warning system, alerting operators to potential hazards before they escalate into major incidents. This early detection is vital for preventing accidents and minimizing damage.

- Automatic alerts to operators: Automated alerts are instantly dispatched to operators, providing sufficient time for intervention and corrective actions.

- Integration with safety shutdown systems: In critical situations, the system can automatically trigger safety shutdown systems, preventing catastrophic events.

- Improved response times to emergencies: Faster response times to emergencies are ensured through immediate alerts and automated responses, significantly reducing the impact of incidents.

Enhanced Risk Assessment

The patent incorporates AI to refine traditional risk assessment methodologies, providing more accurate and comprehensive evaluations of potential hazards. This data-driven approach leads to better resource allocation and improved safety protocols.

- Data-driven risk analysis: AI analyzes vast amounts of operational data to identify previously unrecognized risks and vulnerabilities within the process.

- Identification of previously unrecognized risks: The AI's ability to identify patterns and anomalies often reveals risks that would be overlooked using traditional methods.

- Improved risk mitigation strategies: By analyzing the root causes of past incidents and predicting potential future risks, the AI helps develop more effective risk mitigation strategies.

- Optimization of safety protocols: This results in more effective safety protocols, tailored to the specific risks identified, enhancing the overall safety profile.

Benefits of AI in Process Safety

The integration of AI into process safety offers a multitude of benefits, leading to safer, more efficient, and compliant operations.

Reduced Accidents and Incidents

The proactive nature of AI-driven safety systems significantly minimizes the chance of accidents and incidents, protecting both personnel and equipment.

- Lower incident rates: Predictive maintenance and real-time anomaly detection contribute to a demonstrably lower rate of accidents and incidents.

- Reduced downtime: Proactive maintenance significantly reduces unplanned downtime, minimizing production losses.

- Improved worker safety: Early warning systems and automated safety measures contribute to a safer working environment for personnel.

- Decreased environmental impact: Prevention of accidents minimizes the risk of environmental damage and pollution.

Increased Efficiency and Productivity

By optimizing maintenance schedules and preventing unexpected shutdowns, AI contributes to increased efficiency and productivity.

- Reduced maintenance costs: Predictive maintenance optimizes maintenance schedules, reducing unnecessary maintenance and associated costs.

- Improved operational uptime: Reduced downtime results in improved operational uptime and increased production output.

- Enhanced production output: By optimizing the process and preventing unexpected disruptions, AI enhances overall production output.

- Optimized resource allocation: Data-driven insights facilitate optimized resource allocation, improving overall efficiency.

Improved Compliance and Regulatory Adherence

AI-driven safety systems can help companies meet regulatory requirements and demonstrate their commitment to safety.

- Automated data logging and reporting: The system automates data logging and reporting, simplifying compliance audits.

- Easier compliance audits: Automated documentation and reporting simplify compliance audits, reducing the administrative burden.

- Proactive identification of non-compliance issues: The AI system proactively identifies potential non-compliance issues, allowing for timely corrective actions.

Future Implications and Potential Applications

This groundbreaking patent opens doors to wider application of AI across various process industries, including refining, petrochemicals, pharmaceuticals, and food processing. Future developments might incorporate advanced AI techniques like deep learning and reinforcement learning for even greater accuracy and efficiency. The integration of AI with other emerging technologies like the Industrial Internet of Things (IIoT) will further enhance process safety and operational efficiency.

Conclusion

This innovative AI-driven patent represents a significant advancement in process safety, offering a powerful toolkit to reduce hazards and improve operational efficiency. By leveraging the predictive capabilities of AI, companies can proactively mitigate risks, minimizing accidents and maximizing productivity. Investing in AI for process safety is not just a strategic advantage; it is a crucial step towards building safer, more resilient, and efficient industrial operations. Learn more about the applications of AI in process safety and how this groundbreaking patent can revolutionize your safety protocols. Contact us today to explore how AI hazard reduction can benefit your organization and how to implement AI safety systems within your operations.

Featured Posts

-

Jay Z Blue Ivy And Rumi At The Super Bowl A Look At Family Fashion And Beyonces Absence

Apr 30, 2025

Jay Z Blue Ivy And Rumi At The Super Bowl A Look At Family Fashion And Beyonces Absence

Apr 30, 2025 -

Family Accuses San Diego Jail Of Neglect In Inmates Torture Death

Apr 30, 2025

Family Accuses San Diego Jail Of Neglect In Inmates Torture Death

Apr 30, 2025 -

The Reasons Behind Beyonce And Jay Zs Choice To Keep Son Sir Carter Out Of The Public Eye

Apr 30, 2025

The Reasons Behind Beyonce And Jay Zs Choice To Keep Son Sir Carter Out Of The Public Eye

Apr 30, 2025 -

Amanda Owen And Clive Owen Discussing Future Plans Post Divorce

Apr 30, 2025

Amanda Owen And Clive Owen Discussing Future Plans Post Divorce

Apr 30, 2025 -

Trade Shows Key Marketing Touchpoints For Schneider Electrics Success

Apr 30, 2025

Trade Shows Key Marketing Touchpoints For Schneider Electrics Success

Apr 30, 2025

Latest Posts

-

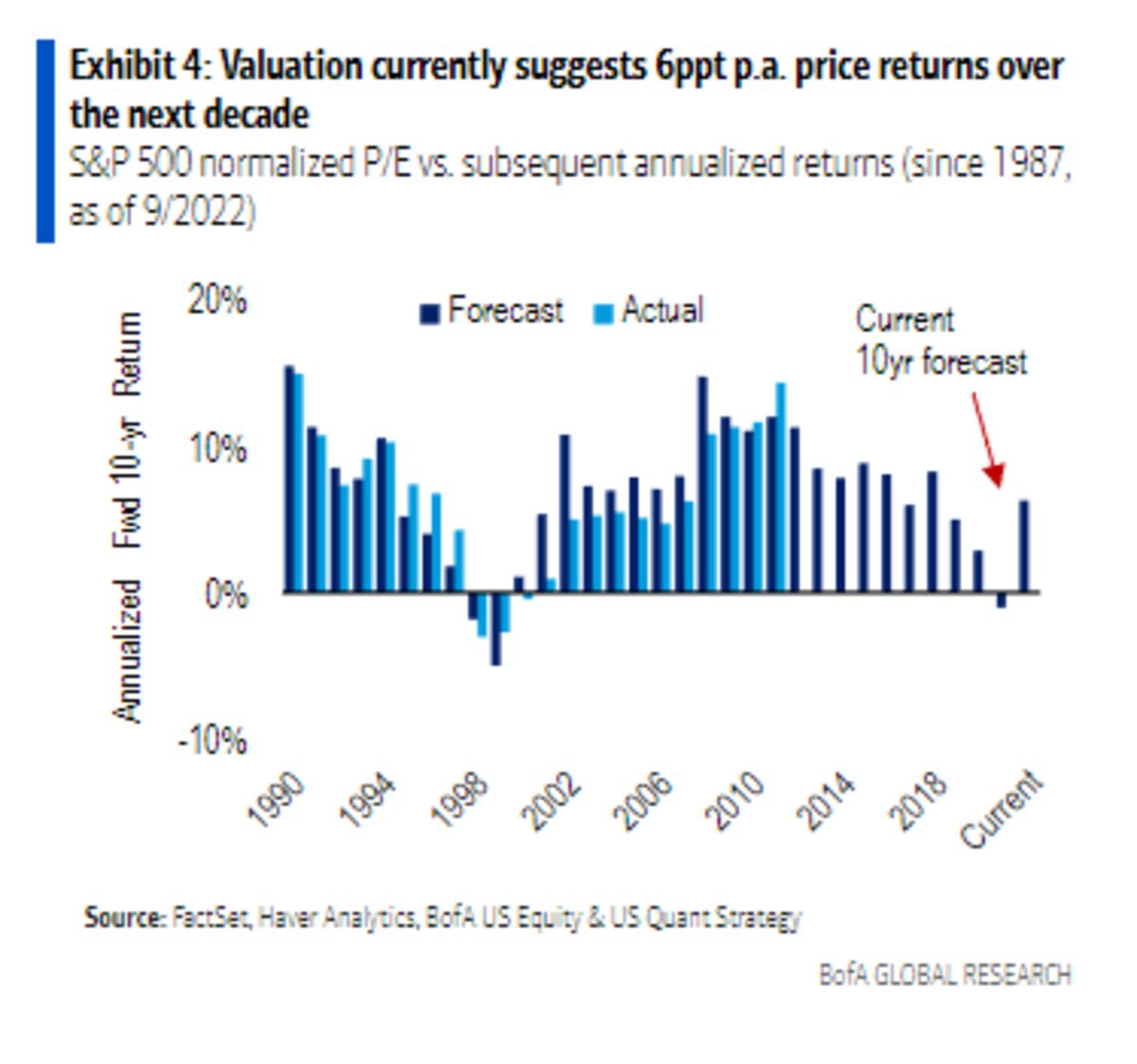

Bof A On Stock Market Valuations A Reasoned Perspective For Investors

Apr 30, 2025

Bof A On Stock Market Valuations A Reasoned Perspective For Investors

Apr 30, 2025 -

Stock Market Valuation Concerns Bof A Offers Reassurance

Apr 30, 2025

Stock Market Valuation Concerns Bof A Offers Reassurance

Apr 30, 2025 -

The Bof A Perspective On Elevated Stock Market Valuations

Apr 30, 2025

The Bof A Perspective On Elevated Stock Market Valuations

Apr 30, 2025 -

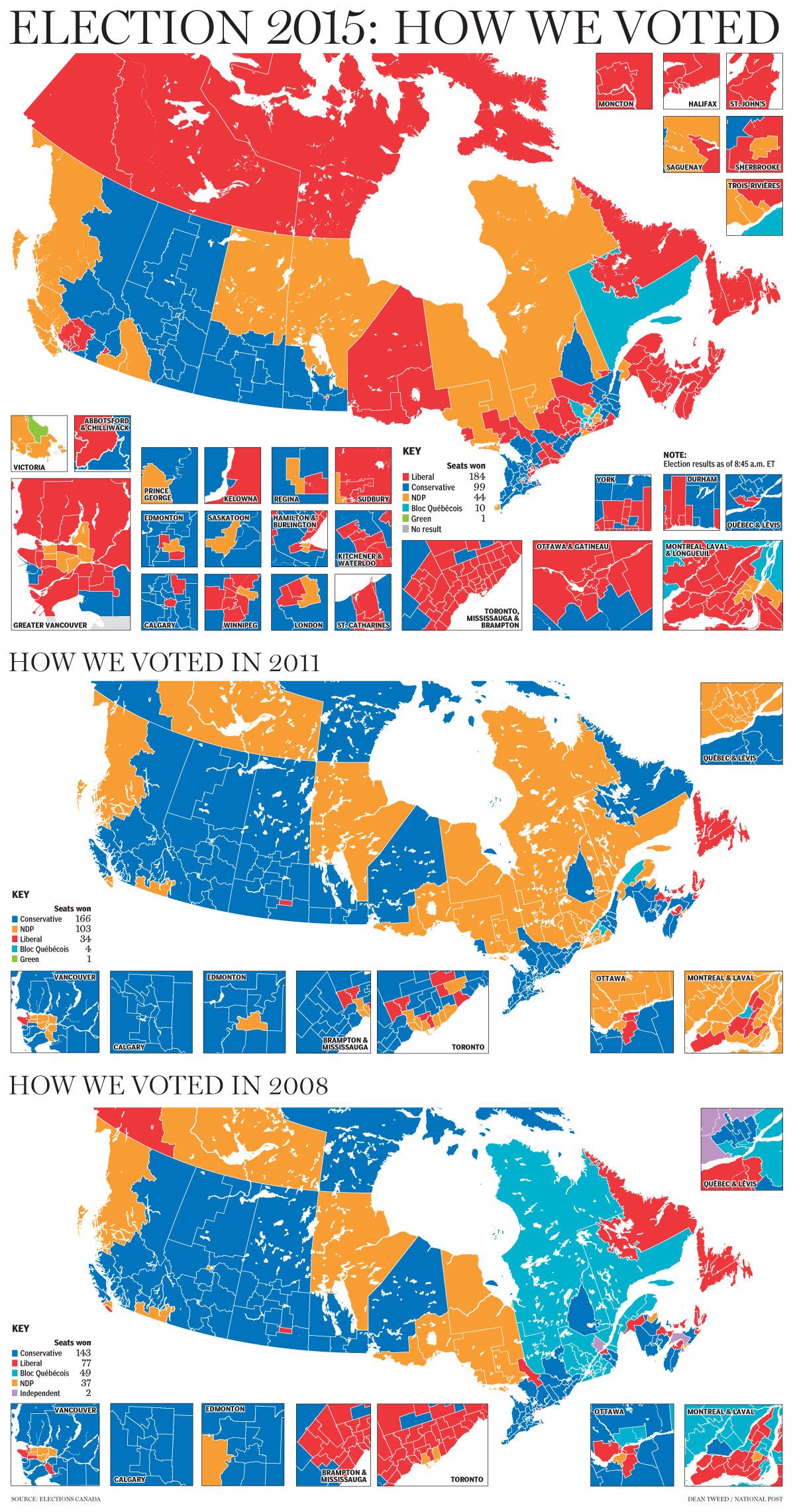

Canadian Election Results Poilievres Unexpected Defeat

Apr 30, 2025

Canadian Election Results Poilievres Unexpected Defeat

Apr 30, 2025 -

Analysis Pierre Poilievres Election Loss And Its Impact

Apr 30, 2025

Analysis Pierre Poilievres Election Loss And Its Impact

Apr 30, 2025