Ford's EV Strategy: Sharing Battery Production With Nissan

Table of Contents

The Rationale Behind Ford's Joint Venture with Nissan

Ford's decision to partner with Nissan on battery production stems from a multi-pronged strategy aimed at optimizing efficiency and securing its future in the EV sector.

Reducing Costs and Increasing Efficiency

The economic benefits of shared battery production are substantial. Economies of scale significantly reduce per-unit battery costs, a crucial factor in making EVs more affordable and accessible to a wider consumer base. This joint venture allows for shared investment in research and development (R&D), minimizing individual capital expenditure and accelerating technological advancements.

- Lower per-unit battery costs: Sharing production facilities and resources drastically lowers the cost of individual batteries, making Ford EVs more competitive in the market.

- Faster production timelines: Combined expertise and resources translate into quicker production and deployment of new battery technologies.

- Shared R&D investment: Joint funding reduces the financial burden on each company, allowing for more ambitious research and development projects.

- Access to Nissan's battery expertise: Nissan's extensive experience in battery technology provides Ford with valuable knowledge and capabilities.

Securing Battery Supply Chains

The EV industry faces significant challenges in securing a reliable supply of batteries. Raw materials are often sourced from geographically concentrated regions, creating vulnerability to geopolitical instability and supply chain disruptions. This joint venture mitigates these risks.

- Mitigation of supply chain risks: Diversifying sourcing and production locations reduces reliance on single suppliers, making the supply chain more resilient.

- Diversification of sourcing: Access to multiple sources of raw materials and manufacturing expertise enhances supply chain security.

- Enhanced geopolitical stability: Reducing reliance on single-source suppliers from potentially unstable regions enhances the overall stability of the supply chain.

Accelerating EV Adoption

Ford's partnership with Nissan is a direct investment in its goal of accelerating EV adoption. By increasing production volume and ensuring a stable battery supply, Ford can expand its EV offerings and make them more readily available to consumers.

- Increased production volume: Joint production facilities lead to a substantial increase in the number of batteries produced, directly boosting Ford's EV output.

- Wider availability of Ford EVs: Increased production capacity translates into more Ford EVs available for purchase, satisfying growing consumer demand.

- Competitive pricing: Lower battery costs contribute to more competitive pricing for Ford's EVs, making them more attractive to buyers.

Details of the Battery Production Collaboration

The Ford-Nissan battery production collaboration involves significant investment and detailed planning to ensure a seamless and efficient operation.

Joint Facilities and Investment

While specific details regarding plant locations and investment amounts may vary depending on ongoing agreements, the commitment from both Ford and Nissan represents a substantial investment in future EV production. The planned facilities are expected to utilize advanced manufacturing techniques to maximize efficiency and minimize environmental impact.

- Specific plant locations and capacities: (Insert specific details if available from official sources. Otherwise, replace with a general statement about planned global capacity expansion)

- Investment amounts: (Insert specific details if available from official sources. Otherwise, replace with a general statement about significant joint investment)

- Technology sharing agreements: Both companies will likely share their respective battery technologies and expertise to optimize the production process.

Battery Technology and Specifications

The partnership will focus on producing high-performance, advanced batteries to power the next generation of Ford EVs. The specific battery chemistry and specifications will be crucial to the success of this venture.

- Battery chemistry: (Specify the type of battery technology being employed, e.g., lithium-ion, solid-state, etc.)

- Energy density: (Provide information about the energy density of the batteries, a key factor affecting vehicle range)

- Range capabilities: (Specify the expected range of Ford EVs powered by these batteries)

- Charging times: (Provide details about the expected charging times)

- Lifespan: (Detail the expected lifespan of the batteries)

Environmental Impact and Sustainability

Ford and Nissan are committed to ensuring that the battery production process is environmentally responsible. This includes minimizing the carbon footprint and using recycled materials where possible.

- Use of recycled materials: The joint venture will prioritize the use of recycled materials in battery production to reduce reliance on newly mined resources.

- Reduction of carbon emissions: The companies will implement measures to minimize carbon emissions throughout the production process.

- Responsible sourcing of raw materials: Sustainable sourcing of raw materials will be a key priority, focusing on ethical and environmentally sound practices.

Implications for the EV Market and Competitors

The Ford-Nissan battery partnership has profound implications for the competitive landscape of the EV market and the broader automotive industry.

Increased Competition

The collaboration will undoubtedly intensify competition within the EV market. The increased production capacity and lower battery costs will allow Ford to offer more competitive pricing and a wider range of EVs, putting pressure on other automakers.

- Impact on pricing: Lower battery costs will translate into more competitive pricing for Ford EVs.

- Market share: Increased production and wider availability will likely lead to an increase in Ford's market share.

- Innovation: The shared R&D efforts will spur innovation in battery technology, potentially leading to breakthroughs that benefit both companies.

- Competitive landscape: The partnership will significantly alter the competitive dynamics of the EV market, forcing other players to adapt.

Technological Advancements

The joint venture has the potential to drive significant technological advancements in battery technology and EV infrastructure.

- Advancements in battery technology: Shared R&D will accelerate the development of more efficient, longer-lasting, and safer batteries.

- Improvements in charging infrastructure: The increased demand for EVs may spur investment in charging infrastructure, benefiting consumers.

- Potential spin-off innovations: The collaboration could lead to breakthroughs with applications beyond the automotive industry.

Future of Ford's EV Strategy

This collaboration is a cornerstone of Ford's long-term EV strategy, setting the stage for significant growth and market expansion.

- Expansion into new EV segments: The increased production capacity will enable Ford to expand its offerings into new EV segments.

- Global market reach: The partnership will strengthen Ford's global presence in the EV market.

- Technological leadership: The collaborative efforts will help solidify Ford's position as a leader in EV technology.

Conclusion

Ford's joint battery production venture with Nissan represents a strategic masterstroke in its EV strategy. By sharing production costs, securing supply chains, and accelerating technological advancements, Ford is significantly enhancing its competitiveness in the rapidly growing EV market. This collaboration promises lower costs, increased production, and ultimately, faster adoption of electric vehicles. Learn more about Ford's EV strategy and its commitment to a sustainable future of electric mobility. Explore Ford's innovative approach to electric vehicle technology and the impact it's having on the global automotive industry.

Featured Posts

-

Experience De Conduite Le Matin Auto Et L Alfa Romeo Junior 1 2 Turbo Speciale

May 22, 2025

Experience De Conduite Le Matin Auto Et L Alfa Romeo Junior 1 2 Turbo Speciale

May 22, 2025 -

Near Misses And Outages Investigating The Risks Of Air Traffic Control System Failures

May 22, 2025

Near Misses And Outages Investigating The Risks Of Air Traffic Control System Failures

May 22, 2025 -

Blake Lively And Recent Allegations What We Know So Far

May 22, 2025

Blake Lively And Recent Allegations What We Know So Far

May 22, 2025 -

The Shifting Sands Of The Chinese Auto Market Case Study Bmw And Porsche

May 22, 2025

The Shifting Sands Of The Chinese Auto Market Case Study Bmw And Porsche

May 22, 2025 -

Kwartaalcijfers Abn Amro Forse Stijging In Aex

May 22, 2025

Kwartaalcijfers Abn Amro Forse Stijging In Aex

May 22, 2025

Latest Posts

-

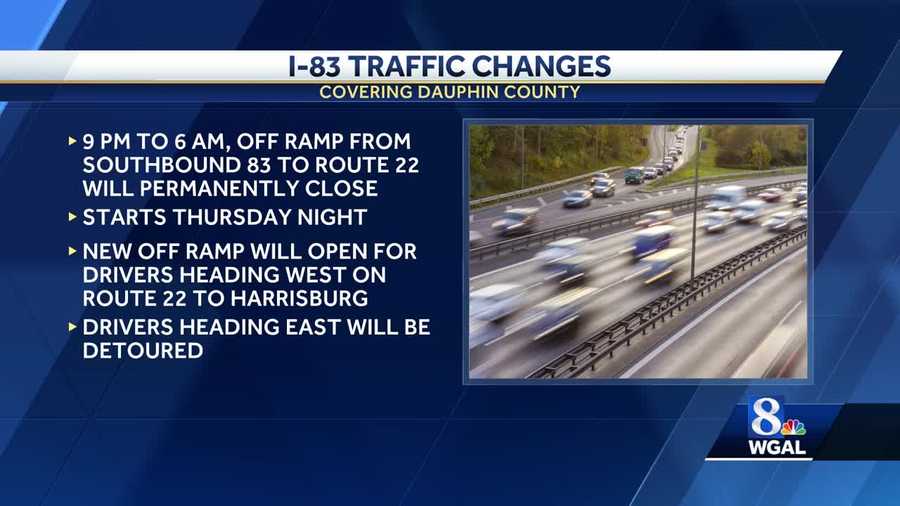

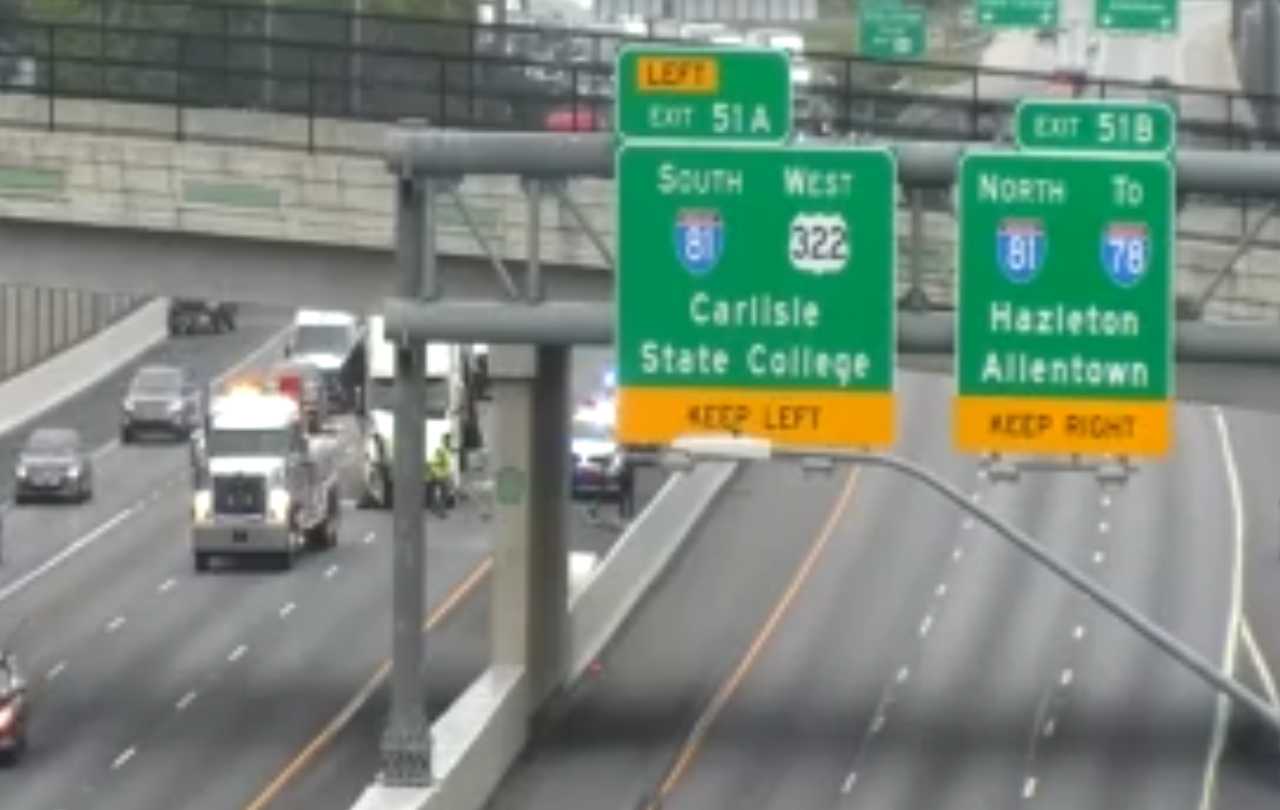

Interstate 83 Traffic Delays Due To Produce Truck Overturn

May 22, 2025

Interstate 83 Traffic Delays Due To Produce Truck Overturn

May 22, 2025 -

Route 283 Fed Ex Truck Inferno Lancaster County Incident

May 22, 2025

Route 283 Fed Ex Truck Inferno Lancaster County Incident

May 22, 2025 -

I 83 Closed Following Tractor Trailer Produce Spill

May 22, 2025

I 83 Closed Following Tractor Trailer Produce Spill

May 22, 2025 -

Lancaster County Fed Ex Truck Catches Fire On Route 283

May 22, 2025

Lancaster County Fed Ex Truck Catches Fire On Route 283

May 22, 2025 -

Produce Laden Tractor Trailer Crash On I 83

May 22, 2025

Produce Laden Tractor Trailer Crash On I 83

May 22, 2025