Securing Dysprosium Supply Chains: Challenges And Opportunities For The EV Sector

Table of Contents

Geopolitical Risks and Supply Chain Vulnerabilities

The current dysprosium supply chain is characterized by significant geopolitical risks and vulnerabilities. A primary concern is the concentration of dysprosium production.

Concentration of Dysprosium Production

China currently dominates dysprosium mining and processing, holding a near-monopoly on the global supply. This creates substantial risks for EV manufacturers globally.

- Dependence on a single nation: This heavy reliance exposes the EV industry to political instability in China, trade disputes, and potential export restrictions, potentially halting or severely limiting the production of EVs. Any disruption in Chinese dysprosium exports could have devastating consequences for the global EV market.

- Limited price transparency and volatility: The concentrated nature of the market limits price transparency and increases the risk of price volatility. This makes it difficult for EV manufacturers to accurately forecast costs and plan for future production. Price spikes could severely impact the profitability and competitiveness of EV manufacturers.

- Urgent need for diversification: Diversifying dysprosium sources is crucial to mitigate these geopolitical risks and ensure a stable supply for the growing EV industry. A diversified supply chain is less susceptible to disruptions from a single source.

Mining and Processing Challenges

Beyond geopolitical concerns, the extraction and processing of dysprosium present significant challenges. Dysprosium mining is a complex, environmentally demanding, and energy-intensive process.

- Environmental regulations and costs: Increasingly stringent environmental regulations and sustainability standards are adding to the cost and complexity of dysprosium extraction and processing. Meeting these standards requires significant investment in environmentally friendly technologies.

- Lack of efficient recycling: The absence of a robust and efficient recycling infrastructure for dysprosium exacerbates supply constraints. Recycling end-of-life products containing dysprosium is crucial for improving resource efficiency and reducing reliance on primary mining.

- Technological advancements needed: Technological advancements in extraction and processing techniques are necessary to improve efficiency, reduce environmental impact, and lower the overall cost of dysprosium production. This includes research into less energy-intensive and more environmentally friendly extraction methods.

Opportunities for Sustainable and Secure Dysprosium Supply

Despite the challenges, several opportunities exist to create a more sustainable and secure dysprosium supply chain for the EV sector.

Diversification of Sourcing

Diversifying dysprosium sourcing is paramount to mitigating the risks associated with dependence on a single nation.

- Investing in alternative sources: Exploring and investing in dysprosium mining projects in countries like Australia, the United States, and Canada, is critical. These nations possess significant dysprosium reserves and offer opportunities for creating more diverse and resilient supply chains.

- Strategic partnerships: Establishing strategic partnerships with mining companies in these regions can ensure a more reliable and stable supply of dysprosium. These partnerships should focus on ethical and sustainable mining practices.

- Sustainable mining practices: Supporting ethical and sustainable dysprosium mining practices is vital for long-term supply chain resilience and environmental protection. This includes minimizing environmental impact and ensuring fair labor practices.

Technological Innovations and Recycling

Technological innovation is crucial for enhancing supply chain security and reducing reliance on dysprosium.

- Alternative magnet designs: Research and development into alternative magnet designs that require less or no dysprosium are critical. This includes exploring neodymium-free magnets and other materials with similar magnetic properties.

- Advanced recycling technologies: Investing in advanced recycling technologies to recover dysprosium from end-of-life products like electric motors is essential for improving resource efficiency and reducing reliance on primary mining.

- Circular economy principles: Promoting circular economy principles can significantly improve resource efficiency and reduce the environmental impact of dysprosium mining and processing. This includes designing products for easy disassembly and recycling.

Policy and Regulatory Frameworks for Dysprosium Supply Chain Security

Governments and international collaboration play a crucial role in securing a reliable dysprosium supply chain.

Government Policies and Incentives

Governments can stimulate a more secure dysprosium supply through supportive policies and incentives.

- Supporting domestic mining and processing: Implementing policies that support domestic dysprosium mining and processing can boost local production and reduce reliance on imports.

- Incentivizing R&D: Providing financial incentives for research and development in alternative magnet technologies and recycling can accelerate innovation and reduce dependence on dysprosium.

- Strategic public-private partnerships: Strategic partnerships between governments and the private sector are crucial for coordinated efforts to develop and implement solutions.

International Collaboration

Global cooperation is essential to address the challenges and opportunities surrounding dysprosium supply chains.

- Sharing best practices: Sharing best practices and collaborating on research and development can accelerate the development of sustainable and efficient dysprosium mining and processing techniques.

- International standards: Establishing international standards for responsible dysprosium mining and processing ensures sustainability and environmental protection.

- Transparency and information sharing: Promoting transparency and information sharing across the dysprosium supply chain builds trust and resilience, mitigating potential disruptions.

Conclusion

Securing reliable dysprosium supply chains is paramount for the successful growth of the electric vehicle sector. While challenges related to geopolitical risks, mining complexities, and environmental concerns persist, there are substantial opportunities to create a more sustainable and secure supply. By diversifying sources, investing in technological innovation, implementing supportive policies, and fostering international collaboration, the EV industry can mitigate vulnerabilities and pave the way for a greener and more resilient future. The future of electric mobility depends on proactive strategies to address the challenges and seize the opportunities presented by securing robust dysprosium supply chains. Take action today to ensure the long-term viability of your EV initiatives by investing in responsible sourcing and innovative solutions for dysprosium.

Featured Posts

-

Arizona Speedboat Competition Daredevil Attempt Ends In Air

Apr 29, 2025

Arizona Speedboat Competition Daredevil Attempt Ends In Air

Apr 29, 2025 -

The Undervalued Asset Why Middle Managers Are Crucial For Organizational Success

Apr 29, 2025

The Undervalued Asset Why Middle Managers Are Crucial For Organizational Success

Apr 29, 2025 -

Snow Fox Delays And Closings Tuesday February 11th Updates

Apr 29, 2025

Snow Fox Delays And Closings Tuesday February 11th Updates

Apr 29, 2025 -

Nyt Spelling Bee February 28 2025 Find The Spangram And All Answers

Apr 29, 2025

Nyt Spelling Bee February 28 2025 Find The Spangram And All Answers

Apr 29, 2025 -

Stock Market Valuations Bof As Rationale For Investor Calm

Apr 29, 2025

Stock Market Valuations Bof As Rationale For Investor Calm

Apr 29, 2025

Latest Posts

-

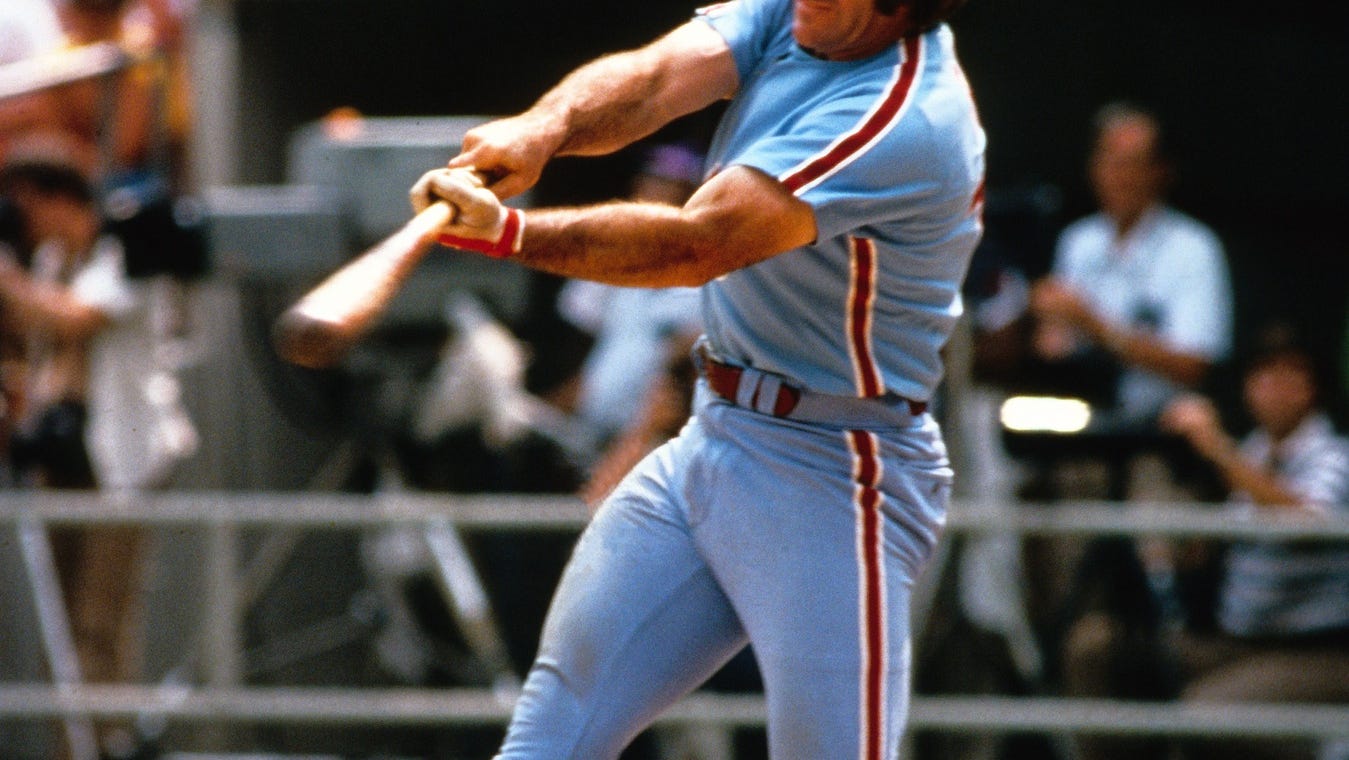

Johnny Damon Pete Rose In Baseball Hall Of Fame Agrees With Trump

Apr 29, 2025

Johnny Damon Pete Rose In Baseball Hall Of Fame Agrees With Trump

Apr 29, 2025 -

Trump To Pardon Pete Rose After His Death Analyzing The Announcement

Apr 29, 2025

Trump To Pardon Pete Rose After His Death Analyzing The Announcement

Apr 29, 2025 -

Will Pete Rose Receive A Posthumous Pardon From Trump

Apr 29, 2025

Will Pete Rose Receive A Posthumous Pardon From Trump

Apr 29, 2025 -

Pete Rose Pardon Trumps Statement And Its Implications

Apr 29, 2025

Pete Rose Pardon Trumps Statement And Its Implications

Apr 29, 2025 -

Trumps Posthumous Pardon For Pete Rose A Presidential Promise

Apr 29, 2025

Trumps Posthumous Pardon For Pete Rose A Presidential Promise

Apr 29, 2025