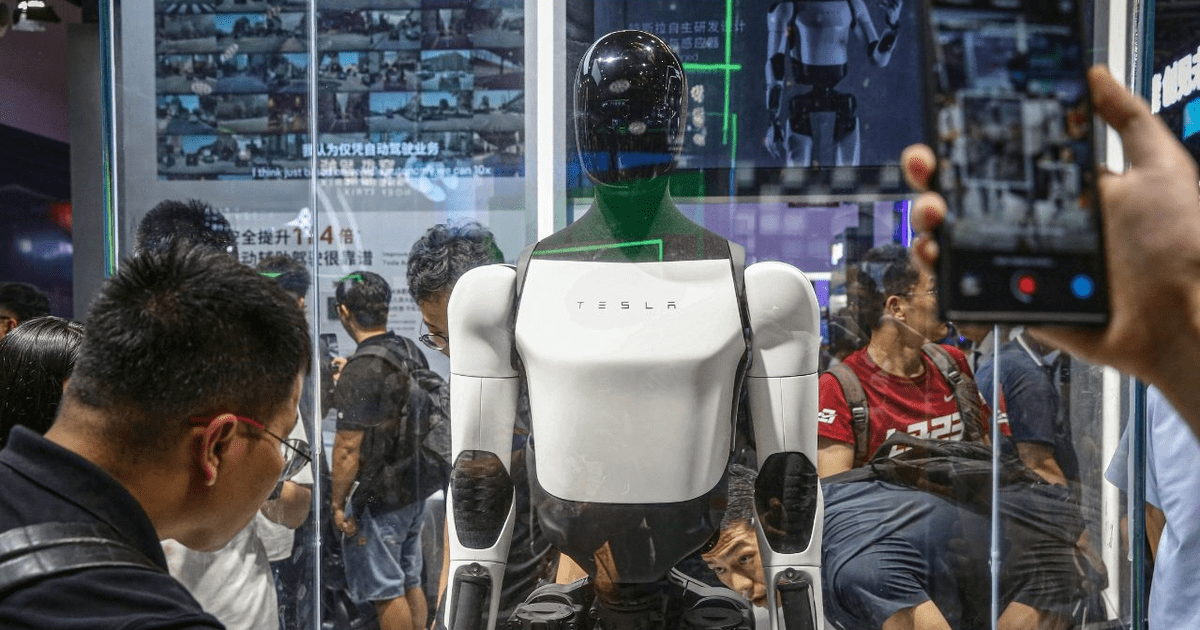

Tesla's Optimus Humanoid Robot Project Faces Setbacks Due To Rare Earth Supply Issues

Table of Contents

The Crucial Role of Rare Earth Minerals in Optimus

Optimus' functionality relies heavily on rare earth elements (REEs). These minerals are not rare in the Earth's crust, but their extraction and processing are complex and concentrated geographically, leading to supply chain vulnerabilities.

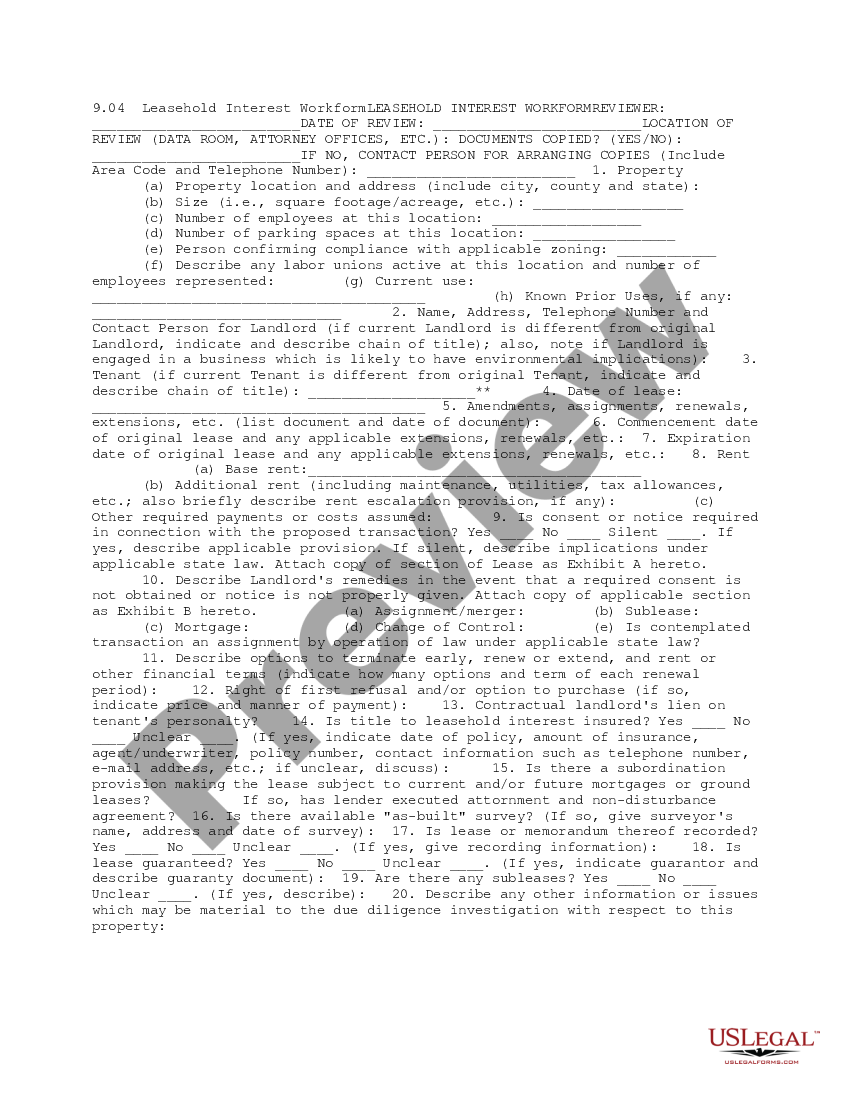

Rare Earths in Motors and Actuators

Optimus' intricate movements depend on powerful, miniature motors and actuators. These components heavily rely on rare earth elements like neodymium, praseodymium, and dysprosium for their magnetic properties.

- Neodymium magnets: Provide high magnetic field strength crucial for motor efficiency, enabling the robot's precise and powerful movements. Without these high-performance magnets, Optimus' agility would be severely compromised.

- Praseodymium and dysprosium: Enhance the magnets' performance at higher temperatures, ensuring consistent operation even during periods of intense activity. These elements are critical for maintaining the robot's stability and preventing overheating.

- Dependence on these elements: Makes Optimus susceptible to supply chain vulnerabilities. Any disruption in the supply of these REEs directly impacts production and potentially delays the robot's launch.

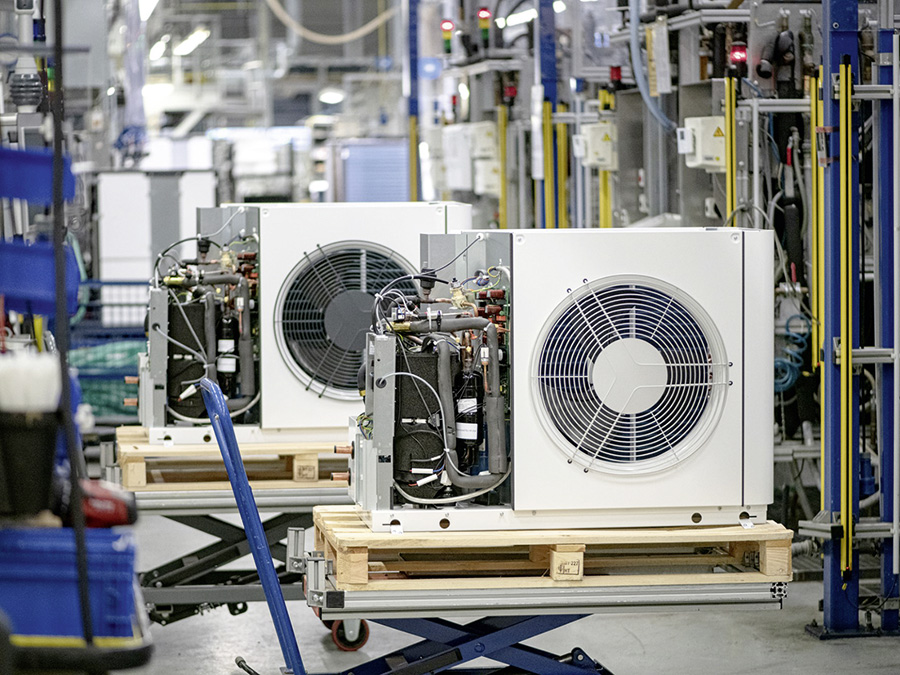

Rare Earths in Sensors and Electronics

The robot's advanced sensing and control systems also require rare earth elements in various components. These elements are integral to the performance and accuracy of the robot's perception and decision-making capabilities.

- Sensors: Utilize rare earth materials for improved sensitivity and accuracy. This allows Optimus to accurately perceive its environment, navigate obstacles, and interact with objects. The precision of these sensors is directly tied to the quality of the REEs used.

- Electronic circuits: May incorporate rare earth elements for enhanced performance, increasing processing speed and efficiency. This contributes to the robot's responsiveness and ability to perform complex tasks.

- High demand: The complex electronics within Optimus contribute to a high demand for these specialized materials, further intensifying the pressure on already strained supply chains.

The Global Rare Earth Supply Chain Crisis

The global supply chain for rare earth elements is fraught with challenges, significantly impacting the production of technology reliant on these materials, including Optimus.

Geopolitical Factors

The majority of rare earth mining and processing is concentrated in a few countries, primarily China. This geographic concentration creates geopolitical risks and price volatility.

- Dependence on a single major supplier: Makes Tesla vulnerable to trade disputes, export restrictions, and potential political maneuvering that could disrupt the flow of these critical materials.

- Price manipulation and supply disruptions: The concentrated supply chain creates potential for price manipulation and supply disruptions, directly impacting manufacturing costs and timelines for Optimus.

- Diversification challenges: Diversifying sourcing is crucial but challenging due to the complex and specialized nature of rare earth mining and processing. Establishing new, reliable sources takes significant time and investment.

Environmental Concerns and Mining Challenges

Rare earth mining is environmentally intensive, raising concerns about sustainability and ethical sourcing. The environmental cost of extracting these materials is a significant factor influencing the overall sustainability of the Optimus project.

- Environmental damage: The extraction process can lead to significant environmental damage, including water pollution, soil erosion, and habitat destruction.

- Sustainable mining practices: Growing public awareness of these environmental impacts is pushing for more sustainable mining practices, increasing the pressure on companies like Tesla to source REEs responsibly.

- Ethical sourcing: Finding ethical and environmentally sound sources of rare earth minerals is critical for Tesla's long-term sustainability and brand reputation.

Potential Consequences for Optimus' Development

The scarcity of rare earths presents significant challenges for Optimus' development and future. These challenges are likely to manifest in several ways.

Delayed Launch and Increased Costs

The scarcity of rare earths can lead to significant delays in Optimus' production and a substantial increase in manufacturing costs.

- Production delays: Delays could impact Tesla's ambitious rollout plans and market entry, potentially losing market share to competitors.

- Increased manufacturing costs: The higher cost of rare earth materials will inevitably increase the overall cost of producing Optimus, potentially affecting its profitability and market competitiveness.

- Business viability: Securing a stable and affordable supply of rare earth minerals will become a key factor influencing the business viability of Optimus.

Impact on Technological Innovation

Supply chain challenges could hinder Tesla's ability to innovate and develop more advanced versions of Optimus.

- Limited access to REEs: Could constrain the integration of cutting-edge features and limit the potential of future iterations of the robot.

- Hampered R&D: Research and development efforts could be hampered by supply chain uncertainty, slowing down the pace of technological advancements.

- Alternative materials: The focus may shift towards exploring and implementing alternative materials, which may compromise performance and functionality compared to REEs.

Conclusion

Tesla's Optimus humanoid robot project represents a significant technological endeavor, but its success is inextricably linked to the availability of rare earth minerals. The ongoing supply chain challenges pose substantial risks, potentially leading to delays, increased costs, and limitations in technological advancements. Addressing these issues through diversification of sourcing, sustainable mining practices, and exploration of alternative materials is crucial for the future of the Optimus project and the wider humanoid robotics industry. To stay informed on the latest developments and challenges surrounding Tesla's ambitious Optimus robot and its reliance on rare earth minerals, continue to follow our updates on this critical topic. Understanding the intricacies of rare earth supply chains is vital for anyone interested in the future of Optimus and humanoid robots.

Featured Posts

-

Selling Sunset Star Exposes La Landlord Price Gouging After Fires

Apr 24, 2025

Selling Sunset Star Exposes La Landlord Price Gouging After Fires

Apr 24, 2025 -

Chainalysis Acquires Ai Startup Alterya Expanding Blockchain Capabilities

Apr 24, 2025

Chainalysis Acquires Ai Startup Alterya Expanding Blockchain Capabilities

Apr 24, 2025 -

A Call For Fiscal Prudence Rebuilding Canadas Economic Future

Apr 24, 2025

A Call For Fiscal Prudence Rebuilding Canadas Economic Future

Apr 24, 2025 -

Hudsons Bay Leasehold Interest 65 Properties Attract Attention

Apr 24, 2025

Hudsons Bay Leasehold Interest 65 Properties Attract Attention

Apr 24, 2025 -

Body Found After Swimmer Disappears Near Shark Infested Israeli Beach

Apr 24, 2025

Body Found After Swimmer Disappears Near Shark Infested Israeli Beach

Apr 24, 2025

Latest Posts

-

Asylunterkuenfte Organisation Optimieren Und Kosten Senken

May 12, 2025

Asylunterkuenfte Organisation Optimieren Und Kosten Senken

May 12, 2025 -

Parliament Demands Halt To Undocumented Labor Migration Influx

May 12, 2025

Parliament Demands Halt To Undocumented Labor Migration Influx

May 12, 2025 -

Verbesserung Der Asylunterkuenfte Einsparungen Von Einer Milliarde Euro Moeglich

May 12, 2025

Verbesserung Der Asylunterkuenfte Einsparungen Von Einer Milliarde Euro Moeglich

May 12, 2025 -

No More Outings Fabers New Approach To Refugee Support

May 12, 2025

No More Outings Fabers New Approach To Refugee Support

May 12, 2025 -

Asylum Volunteer Honors Blocked By Pvv Minister In The Netherlands

May 12, 2025

Asylum Volunteer Honors Blocked By Pvv Minister In The Netherlands

May 12, 2025