The Future Of Electric Motors: Diversifying Supply Chains Away From China

Table of Contents

China's Current Dominance in Electric Motor Manufacturing

Market Share and Production Capacity

China boasts a commanding share of the global electric motor market. Its vast production capacity, driven by significant government investment and a robust domestic supply chain, has made it a central player in the EV ecosystem. This dominance, however, presents considerable geopolitical risks.

- Market Share: Estimates place China's share of global electric motor production at over 70%, although precise figures vary depending on the type of motor and data source.

- Production Volume: Chinese factories produce millions of electric motors annually, catering to both domestic and international EV manufacturers.

- Key Players: Several prominent Chinese companies dominate the sector, controlling key aspects of the supply chain, from raw material sourcing to finished product assembly. These companies benefit from government subsidies, tax incentives, and other supportive policies.

- Reasons for Dominance: China's dominance stems from a combination of factors, including readily available and often cheaper raw materials, government subsidies heavily promoting domestic EV development, a highly skilled and cost-effective workforce, and established supply chains for related components.

Geopolitical Risks and Supply Chain Vulnerabilities

Over-reliance on a single nation for such a critical component as electric motors creates significant vulnerabilities. Geopolitical instability, trade disputes, and unexpected events can easily disrupt the global supply of electric motors.

- Trade Wars and Sanctions: Escalating trade tensions or sanctions could severely restrict the export of electric motors from China, impacting EV production worldwide.

- Political Instability: Internal political shifts or unforeseen circumstances within China could lead to production disruptions or export restrictions.

- Supply Chain Disruptions: Natural disasters, pandemics, or logistical bottlenecks in China can have cascading effects on the global electric motor supply chain, leading to delays and shortages.

- Price Volatility: A concentrated supply chain leaves global EV manufacturers vulnerable to price fluctuations dictated by the Chinese market. Any increase in production costs or export tariffs in China can directly impact the final price of electric vehicles globally.

Strategies for Diversifying Electric Motor Supply Chains

Government Initiatives and Policy Support

Governments worldwide are recognizing the importance of fostering domestic electric motor manufacturing to reduce reliance on China. Many are implementing policies and initiatives to attract investment and boost local production.

- Tax Breaks and Subsidies: Numerous countries are offering generous tax breaks and subsidies to companies investing in electric motor manufacturing facilities within their borders.

- Reshoring and Nearshoring: Governments are actively promoting "reshoring" (returning production to the home country) and "nearshoring" (moving production to nearby countries) to shorten supply chains and reduce geopolitical risks.

- Case Studies: Successful examples include the US's focus on incentivizing domestic battery production, which indirectly boosts electric motor demand, and the European Union's efforts to build a robust and independent battery ecosystem, including electric motors.

Investment in Domestic Manufacturing Capabilities

Companies are actively investing in building or expanding electric motor manufacturing facilities outside China to diversify their supply chains. This involves significant capital expenditure but is seen as crucial for long-term stability and reduced risk.

- New Production Facilities: Major automotive manufacturers and electric motor suppliers are establishing new production facilities in various countries, including North America, Europe, and Southeast Asia.

- Investment Amounts: Billions of dollars are being poured into new factories, research and development, and advanced manufacturing technologies.

- Automation and Technology: Investments often focus on incorporating advanced automation and robotics to enhance efficiency and competitiveness, minimizing reliance on lower-cost labor.

Strategic Partnerships and Collaboration

Collaboration between companies and governments is essential to building resilient and diversified electric motor supply chains. Strategic partnerships accelerate technology transfer, knowledge sharing, and the development of robust ecosystems.

- Joint Ventures: Joint ventures between international companies and local players can help establish manufacturing capabilities and access local expertise.

- Technology Transfer Agreements: Agreements to share crucial technologies and manufacturing processes are vital for building up local competencies.

- R&D Partnerships: Collaborative research and development efforts are vital for developing cutting-edge electric motor technologies and ensuring a competitive edge. Public-private partnerships accelerate innovation.

Technological Advancements and Innovation in Electric Motor Design

Next-Generation Motor Technologies

Advancements in electric motor technology are constantly reshaping the industry, creating opportunities for diversification and innovation. More efficient and powerful motors, along with the use of new materials, are changing the landscape.

- Higher Efficiency Motors: Research into more efficient motor designs reduces energy consumption and improves vehicle range, impacting demand and supply dynamics.

- New Materials: The exploration of new materials, such as rare-earth-free magnets, reduces reliance on specific resources and addresses ethical sourcing concerns.

- Innovative Designs: Innovative designs are making electric motors smaller, lighter, and more adaptable to various applications, leading to more versatile and efficient vehicles.

Focus on Sustainability and Ethical Sourcing

Sustainable and ethical sourcing of materials is increasingly important for electric motors, impacting supply chain management. This includes responsible mining, reduced carbon footprint, and fair labor practices.

- Responsible Mining: Ensuring the responsible sourcing of raw materials such as copper, lithium, and rare earth elements is crucial for environmental and social responsibility.

- Reduced Carbon Footprint: Minimizing the carbon footprint throughout the electric motor's lifecycle, from manufacturing to disposal, is paramount.

- Fair Labor Practices: Adherence to fair labor practices and ethical sourcing of materials throughout the supply chain is crucial to building trust and maintaining a positive brand image. Consumer demand is a key driver of this shift.

Conclusion

Diversifying electric motor supply chains away from China is critical to mitigating geopolitical risks, ensuring stable production, and fostering innovation in the EV industry. Strategies discussed, including government initiatives, investments in domestic manufacturing, strategic partnerships, and technological advancements, are all crucial elements of this diversification process. The future of electric vehicles depends on a resilient and diverse supply chain for electric motors. Governments, businesses, and researchers must work collaboratively to accelerate this diversification process, ensuring a secure and sustainable future for this crucial industry. Invest in the future of electric motors – diversify now.

Featured Posts

-

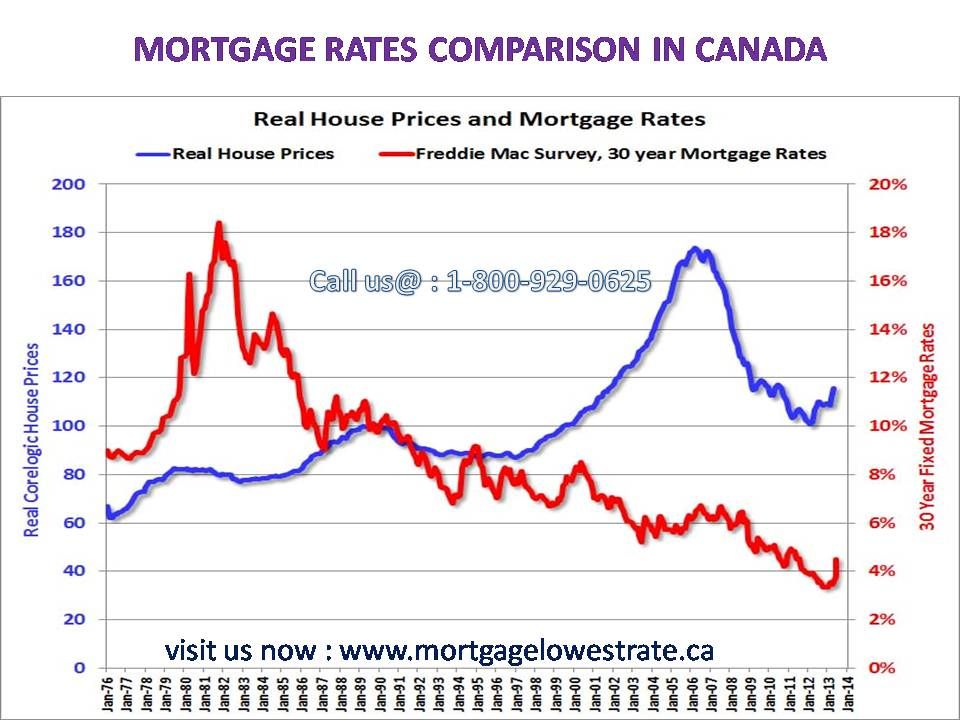

Understanding The Unpopularity Of 10 Year Mortgage Terms In Canada

May 05, 2025

Understanding The Unpopularity Of 10 Year Mortgage Terms In Canada

May 05, 2025 -

Cassidy Hutchinsons Fall Book Release Insights From A Key Jan 6 Witness

May 05, 2025

Cassidy Hutchinsons Fall Book Release Insights From A Key Jan 6 Witness

May 05, 2025 -

Lets Rewatch The Gta Vi Trailer A Frame By Frame Breakdown

May 05, 2025

Lets Rewatch The Gta Vi Trailer A Frame By Frame Breakdown

May 05, 2025 -

Charles Barkleys Playoff Predictions Who Will Win Oilers And Leafs Featured

May 05, 2025

Charles Barkleys Playoff Predictions Who Will Win Oilers And Leafs Featured

May 05, 2025 -

Hollywood At A Standstill The Writers And Actors Joint Strike

May 05, 2025

Hollywood At A Standstill The Writers And Actors Joint Strike

May 05, 2025

Latest Posts

-

Major Blow To Ufc 314 Card Neal Vs Prates Bout Off

May 05, 2025

Major Blow To Ufc 314 Card Neal Vs Prates Bout Off

May 05, 2025 -

Ufc 314 Geoff Neal Vs Carlos Prates Fight Cancelled

May 05, 2025

Ufc 314 Geoff Neal Vs Carlos Prates Fight Cancelled

May 05, 2025 -

Predicting The Winner Chandler Vs Pimblett At Ufc 314

May 05, 2025

Predicting The Winner Chandler Vs Pimblett At Ufc 314

May 05, 2025 -

Ufc 314 Chandler Vs Pimblett Fight Breakdown And Betting Odds

May 05, 2025

Ufc 314 Chandler Vs Pimblett Fight Breakdown And Betting Odds

May 05, 2025 -

Will Chandler Or Pimblett Win Ufc 314 Co Main Event Betting Odds

May 05, 2025

Will Chandler Or Pimblett Win Ufc 314 Co Main Event Betting Odds

May 05, 2025