The Hyundai 650: Inside A Car Carrier At The World's Largest Auto Plant

Table of Contents

The Hyundai 650: A Deep Dive into its Design and Capabilities

The Hyundai 650 car carrier is meticulously engineered for optimal performance in demanding automotive logistics. Its specifications showcase a commitment to efficiency and safety. The Hyundai 650 boasts a substantial carrying capacity, allowing for the simultaneous transport of a significant number of vehicles in a single journey. Its dimensions are carefully calculated to maximize space utilization while remaining maneuverable within the confines of the plant and on highways. Furthermore, the Hyundai 650 incorporates advanced fuel-efficient technologies, minimizing its environmental footprint and reducing operational costs. Safety features are paramount, incorporating advanced braking systems and stability control for secure transportation of valuable cargo.

- Key Features of the Hyundai 650:

- Large Capacity: Able to transport a large number of vehicles per trip, significantly increasing efficiency.

- Automated Loading Systems: Streamlines the loading process, reducing manual labor and increasing speed.

- Improved Fuel Economy: Reduces fuel consumption and minimizes environmental impact.

- Advanced Safety Systems: Ensures the secure and safe transportation of vehicles.

- Durability for Long-Haul Transport: Built to withstand the rigors of continuous operation and long distances.

Logistics within the World's Largest Auto Plant: The Hyundai 650's Role

Moving vehicles within a sprawling auto plant is a complex logistical challenge. The sheer volume of vehicles produced necessitates a highly efficient transportation system. The Hyundai 650 plays a pivotal role in streamlining this process. Its large capacity reduces the number of trips required, minimizing congestion and downtime. The Hyundai 650's integration with other automated systems within the plant ensures smooth and coordinated movement of vehicles from assembly lines to storage areas and ultimately to shipping docks. This integration minimizes delays and contributes significantly to the overall efficiency of the plant's operations, ultimately reducing production costs and lead times.

- Impact on Plant Efficiency:

- Efficient Vehicle Movement: Minimizes bottlenecks and delays in the production process.

- Reduced Transportation Time: Faster movement of vehicles translates to increased productivity.

- Integration with Automated Systems: Seamless integration optimizes the overall logistics flow.

- Optimized Loading and Unloading Processes: Efficient handling minimizes downtime and maximizes output.

- Contribution to Overall Plant Efficiency: A key factor in reducing production costs and improving turnaround times.

Technology and Innovation in the Hyundai 650 and the Auto Plant

The Hyundai 650 is not just a vehicle transporter; it's a technologically advanced piece of equipment. GPS tracking and telematics provide real-time location data, allowing for efficient route planning and monitoring. Remote diagnostics enable proactive maintenance, preventing breakdowns and ensuring continuous operation. Automated loading and unloading systems further enhance efficiency and safety. The Hyundai 650's integration with the plant's overall management system allows for comprehensive data analysis, optimizing processes and improving decision-making.

- Technological Advancements:

- GPS Tracking and Monitoring: Real-time location data for optimized routes and efficient fleet management.

- Telematics for Data Analysis: Provides valuable insights for improving operational efficiency.

- Remote Diagnostics and Maintenance: Proactive maintenance reduces downtime and maximizes uptime.

- Automated Loading/Unloading Systems: Increases speed and efficiency while enhancing safety.

- Integration with Plant Management Systems: Streamlines operations and allows for better overall control.

Sustainability and the Hyundai 650: Environmental Impact

The automotive industry is increasingly focused on sustainability. The Hyundai 650 contributes to this goal through its fuel-efficient engine, which significantly reduces emissions compared to older models. The use of sustainable materials in its construction further minimizes its environmental impact. Optimized route planning minimizes fuel consumption and reduces the overall carbon footprint of the transportation process. These initiatives align with the growing demand for environmentally responsible automotive manufacturing.

- Sustainability Initiatives:

- Fuel-Efficient Engine: Reduces fuel consumption and minimizes greenhouse gas emissions.

- Reduced Emissions: Contributes to cleaner air and a smaller carbon footprint.

- Use of Sustainable Materials: Minimizes the use of non-renewable resources.

- Optimized Route Planning for Fuel Savings: Reduces fuel consumption and minimizes environmental impact.

- Contribution to a Greener Automotive Industry: Supports efforts towards environmentally responsible manufacturing.

Conclusion: The Hyundai 650: A Key Player in Automotive Logistics

The Hyundai 650 car carrier is more than just a vehicle; it's a crucial element in the efficient and sustainable operation of the world's largest auto plant. Its large capacity, advanced technology, and commitment to sustainability make it a key player in modern automotive logistics. By streamlining transportation, minimizing environmental impact, and integrating seamlessly with automated systems, the Hyundai 650 significantly contributes to the overall efficiency and success of the automotive manufacturing process. Learn more about the Hyundai 650 and its impact on the future of automotive logistics. Discover how this innovative car carrier is shaping the industry!

Featured Posts

-

Sylhet Thriller Zimbabwe Secure First Away Test Win In Two Years

May 23, 2025

Sylhet Thriller Zimbabwe Secure First Away Test Win In Two Years

May 23, 2025 -

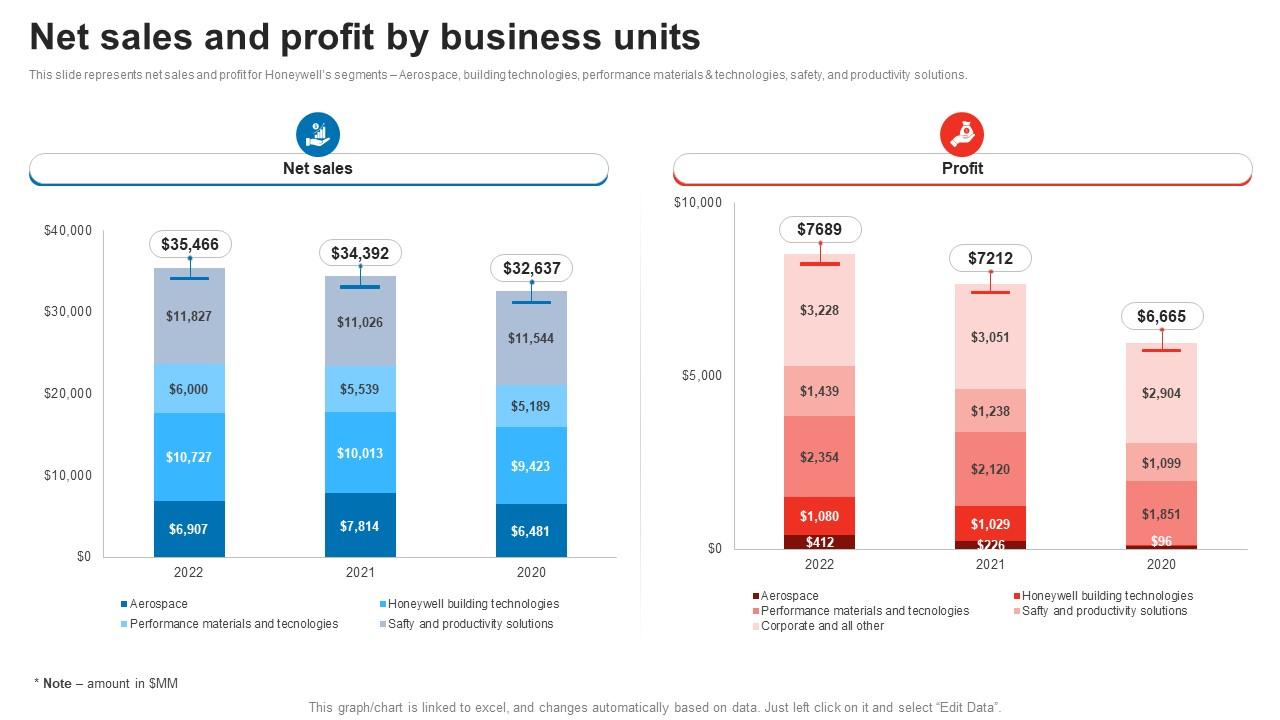

Bt Profit Increase Following Johnson Mattheys Honeywell Sale

May 23, 2025

Bt Profit Increase Following Johnson Mattheys Honeywell Sale

May 23, 2025 -

Analyzing President Ramaphosas Actions Alternative Responses To The White House Situation

May 23, 2025

Analyzing President Ramaphosas Actions Alternative Responses To The White House Situation

May 23, 2025 -

Decoding Big Rig Rock Report 3 12 And Laser 101 7 Results

May 23, 2025

Decoding Big Rig Rock Report 3 12 And Laser 101 7 Results

May 23, 2025 -

Blessing Muzarabani On The Path To 100 Test Wickets

May 23, 2025

Blessing Muzarabani On The Path To 100 Test Wickets

May 23, 2025

Latest Posts

-

Ai Powered Podcast Creation From Repetitive Documents To Engaging Content

May 23, 2025

Ai Powered Podcast Creation From Repetitive Documents To Engaging Content

May 23, 2025 -

Turning Poop Papers Into Podcast Gold An Ai Approach

May 23, 2025

Turning Poop Papers Into Podcast Gold An Ai Approach

May 23, 2025 -

Covid 19 Pandemic Lab Owner Convicted For Fraudulent Test Results

May 23, 2025

Covid 19 Pandemic Lab Owner Convicted For Fraudulent Test Results

May 23, 2025 -

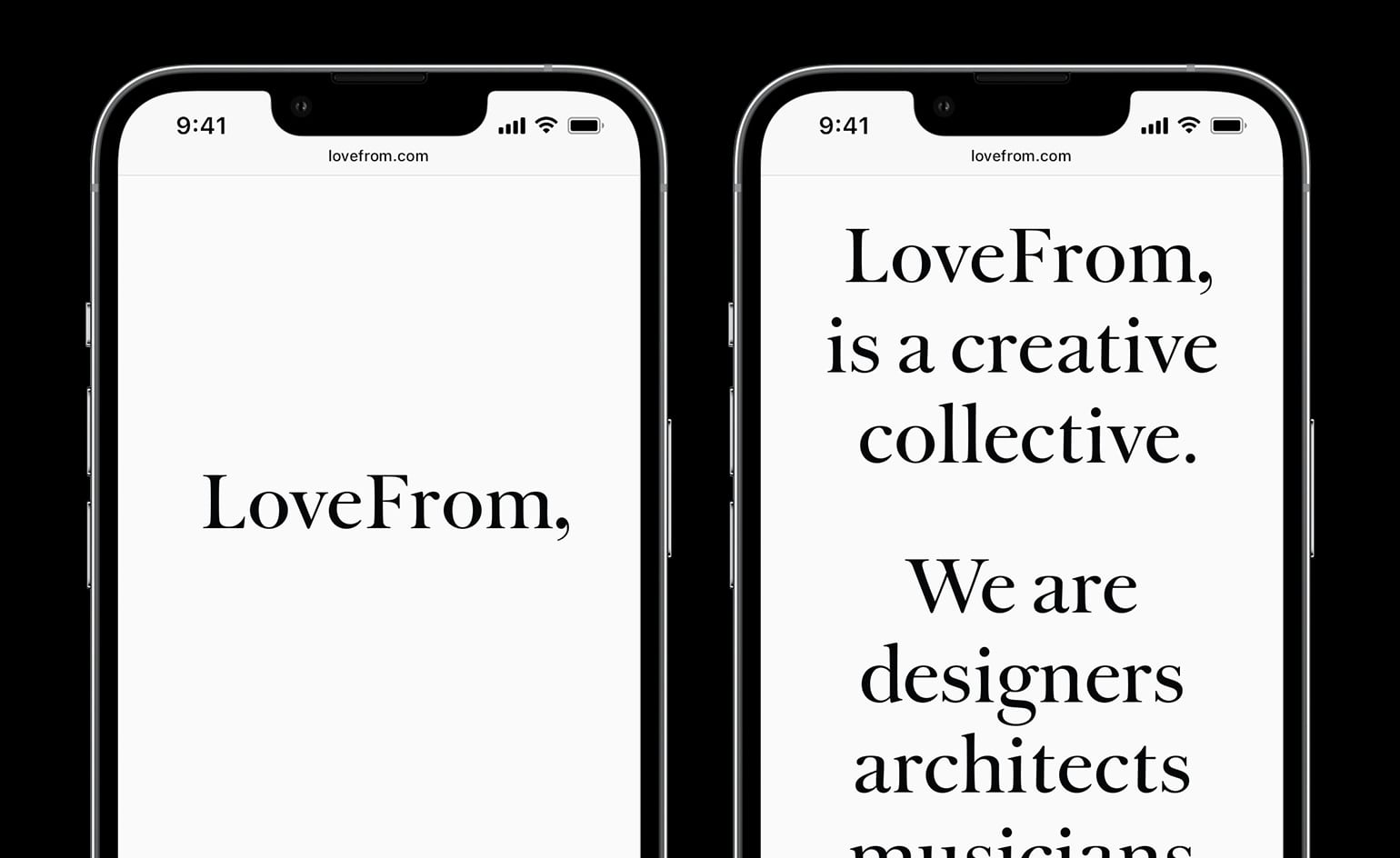

Open Ais Next Move Jony Ives Ai Company In The Spotlight

May 23, 2025

Open Ais Next Move Jony Ives Ai Company In The Spotlight

May 23, 2025 -

The Future Of Ai Hardware Open Ai And Jony Ives Collaboration

May 23, 2025

The Future Of Ai Hardware Open Ai And Jony Ives Collaboration

May 23, 2025