The Reality Of Reshoring: Are Trump's Factory Job Promises Achievable?

Table of Contents

The Allure of Reshoring: Why Bring Manufacturing Back to the US?

The appeal of reshoring—bringing manufacturing operations back to the United States—rests on several compelling arguments. It's not simply about nostalgia for a bygone era of American manufacturing; it's about building a more resilient, secure, and prosperous future.

-

Reduced dependence on foreign supply chains (supply chain resilience): The COVID-19 pandemic starkly highlighted the vulnerabilities of relying heavily on global supply chains. Reshoring offers a path towards greater self-sufficiency and reduces disruptions caused by geopolitical instability or unforeseen events. This is crucial for national security and economic stability.

-

Increased domestic employment and economic growth: Bringing manufacturing jobs back to the US directly translates into job creation, boosting employment numbers and stimulating economic growth at the local, regional, and national levels. This can revitalize struggling communities and reduce economic inequality.

-

Enhanced national security: Reducing reliance on foreign manufacturers for critical goods and technologies strengthens national security. This is particularly important for sectors like defense, pharmaceuticals, and essential infrastructure.

-

Improved environmental impact: Shorter transportation distances associated with domestic manufacturing lead to reduced carbon emissions and a smaller environmental footprint. This aligns with sustainability goals and contributes to a cleaner environment.

-

Support for American communities and revitalization of struggling regions: Reshoring can revitalize communities hit hard by the decline of manufacturing, providing jobs and economic opportunities where they are most needed. This can help reverse population decline and improve the overall quality of life in these areas. Keywords: domestic manufacturing, economic growth, national security, supply chain, American-made.

The Challenges of Reshoring: Why It's Not Easy

While the benefits of reshoring are clear, the path is not without significant hurdles. Several key challenges stand in the way of a wholesale return of manufacturing jobs to the US.

Higher Labor Costs in the US

One of the most significant obstacles is the considerable difference in labor costs between the US and other manufacturing hubs like China, Vietnam, and Mexico. American wages are substantially higher, making it more expensive to produce goods domestically.

-

Automation's role in mitigating labor cost differentials: Automation and advanced manufacturing technologies can help offset higher labor costs by increasing productivity and efficiency. Investing in robotics and other technologies can make domestic manufacturing more competitive.

-

Exploring the potential for upskilling and reskilling the American workforce: Investing in workforce development programs is crucial. Training and education initiatives can equip American workers with the skills needed for modern manufacturing jobs, improving their competitiveness and earning potential.

-

The role of government incentives and tax breaks in offsetting higher labor costs: Government policies, including tax breaks, grants, and subsidies, can play a critical role in incentivizing companies to reshore their operations and reducing the impact of higher labor costs. Keywords: labor costs, automation, workforce development, government incentives, reshoring incentives.

Infrastructure Deficiencies

Outdated and inadequate infrastructure, including transportation networks, energy grids, and digital connectivity, poses a significant challenge to reshoring efforts. Efficient logistics are essential for manufacturing competitiveness.

-

Investing in modernizing infrastructure to support manufacturing: Significant investment in upgrading and expanding infrastructure is necessary to create a supportive environment for domestic manufacturing. This includes improvements to roads, railways, ports, and broadband access.

-

The long-term costs and benefits of infrastructure improvements: While the initial investment in infrastructure modernization is substantial, the long-term economic benefits—increased productivity, reduced transportation costs, and enhanced competitiveness—far outweigh the costs.

-

The impact of inadequate infrastructure on manufacturing competitiveness: Poor infrastructure leads to increased transportation costs, delays, and inefficiencies, making it difficult for domestic manufacturers to compete with those in countries with more modern infrastructure. Keywords: infrastructure, transportation, energy, logistics, supply chain infrastructure.

Competition from Other Countries

The US faces fierce competition from other countries aggressively vying for manufacturing investment. These countries often offer lower labor costs, tax incentives, and other advantages.

-

Comparative analysis of manufacturing costs and incentives in competing nations (e.g., Mexico, China, Vietnam): A thorough understanding of the cost structures and incentives offered by competing nations is essential for developing effective reshoring strategies.

-

The importance of technological innovation and advanced manufacturing techniques: Investing in research and development, and adopting advanced manufacturing technologies, is crucial for enhancing the competitiveness of US manufacturers.

-

The role of trade agreements and tariffs in influencing reshoring decisions: Trade policies, including tariffs and trade agreements, significantly impact the cost of goods and the attractiveness of different manufacturing locations. Keywords: global competition, manufacturing costs, foreign investment, trade agreements, tariffs.

Successful Reshoring Case Studies: What Works?

While reshoring faces significant challenges, some companies have successfully brought manufacturing operations back to the US. Their experiences offer valuable insights into effective strategies. For example, some companies have focused on niche markets requiring specialized skills, allowing them to command premium prices and offset higher labor costs. Others have leveraged automation to significantly increase efficiency. Government support, through incentives and tax breaks, has also played a crucial role in several successful reshoring initiatives. Keywords: reshoring success stories, case studies, best practices, successful reshoring strategies.

The Future of Reshoring: A Realistic Outlook

The future of reshoring hinges on several factors, including technological advancements, policy changes, and evolving global dynamics.

-

The potential impact of automation and artificial intelligence on reshoring: Automation and AI have the potential to significantly increase productivity and reduce labor costs, making domestic manufacturing more competitive.

-

The role of government policies in encouraging reshoring initiatives: Government policies, including tax incentives, infrastructure investments, and workforce development programs, will continue to play a vital role in shaping the future of reshoring.

-

The long-term economic and social benefits of a reshored manufacturing sector: A reshored manufacturing sector can lead to substantial long-term economic and social benefits, including increased employment, improved national security, and enhanced economic resilience. Keywords: future of manufacturing, automation, AI, government policy, economic impact.

Conclusion

Bringing manufacturing jobs back to America—reshoring—presents both significant challenges and substantial opportunities. While completely fulfilling the ambitious promises made regarding reshoring is complex, strategic investments in automation, infrastructure, and workforce development, coupled with supportive government policies, can make significant progress. The complete realization of the promises surrounding reshoring may be a long-term process, but understanding the complexities is crucial. Let's work together to develop effective strategies to bring manufacturing jobs back to America and build a stronger, more resilient economy. Continue the conversation by sharing your thoughts on the feasibility of reshoring in the comments below.

Featured Posts

-

Pro D2 Colomiers Contre Oyonnax Et Montauban Contre Brive Un Week End De Rugby Intense

May 20, 2025

Pro D2 Colomiers Contre Oyonnax Et Montauban Contre Brive Un Week End De Rugby Intense

May 20, 2025 -

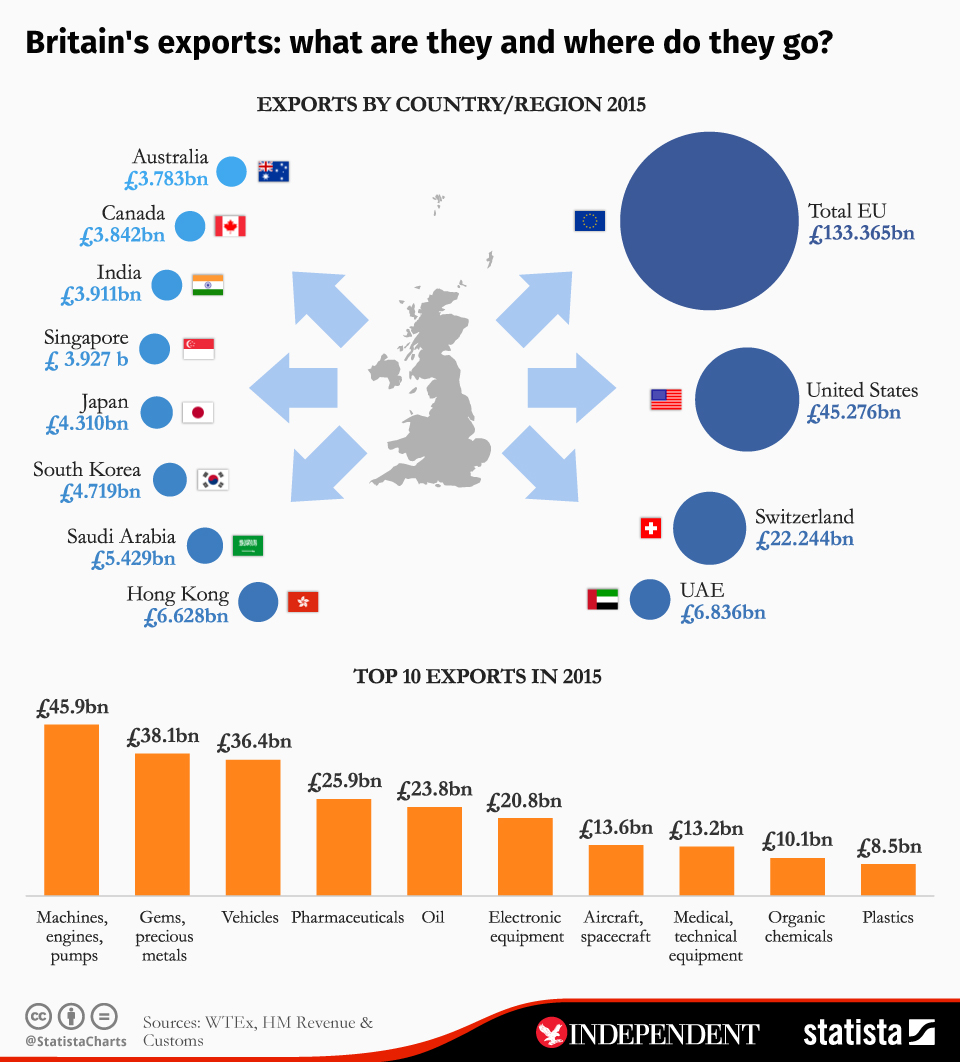

Analysis Brexits Impact On Uk Luxury Exports To The Eu

May 20, 2025

Analysis Brexits Impact On Uk Luxury Exports To The Eu

May 20, 2025 -

Festival Da Cunha Em Manaus Isabelle Nogueira Promove Imersao Cultural Na Amazonia

May 20, 2025

Festival Da Cunha Em Manaus Isabelle Nogueira Promove Imersao Cultural Na Amazonia

May 20, 2025 -

Us Credit Downgrade Impact On Dow Futures And The Dollar

May 20, 2025

Us Credit Downgrade Impact On Dow Futures And The Dollar

May 20, 2025 -

Jan 6 Committee Witness Cassidy Hutchinson To Publish Memoir This Fall

May 20, 2025

Jan 6 Committee Witness Cassidy Hutchinson To Publish Memoir This Fall

May 20, 2025

Latest Posts

-

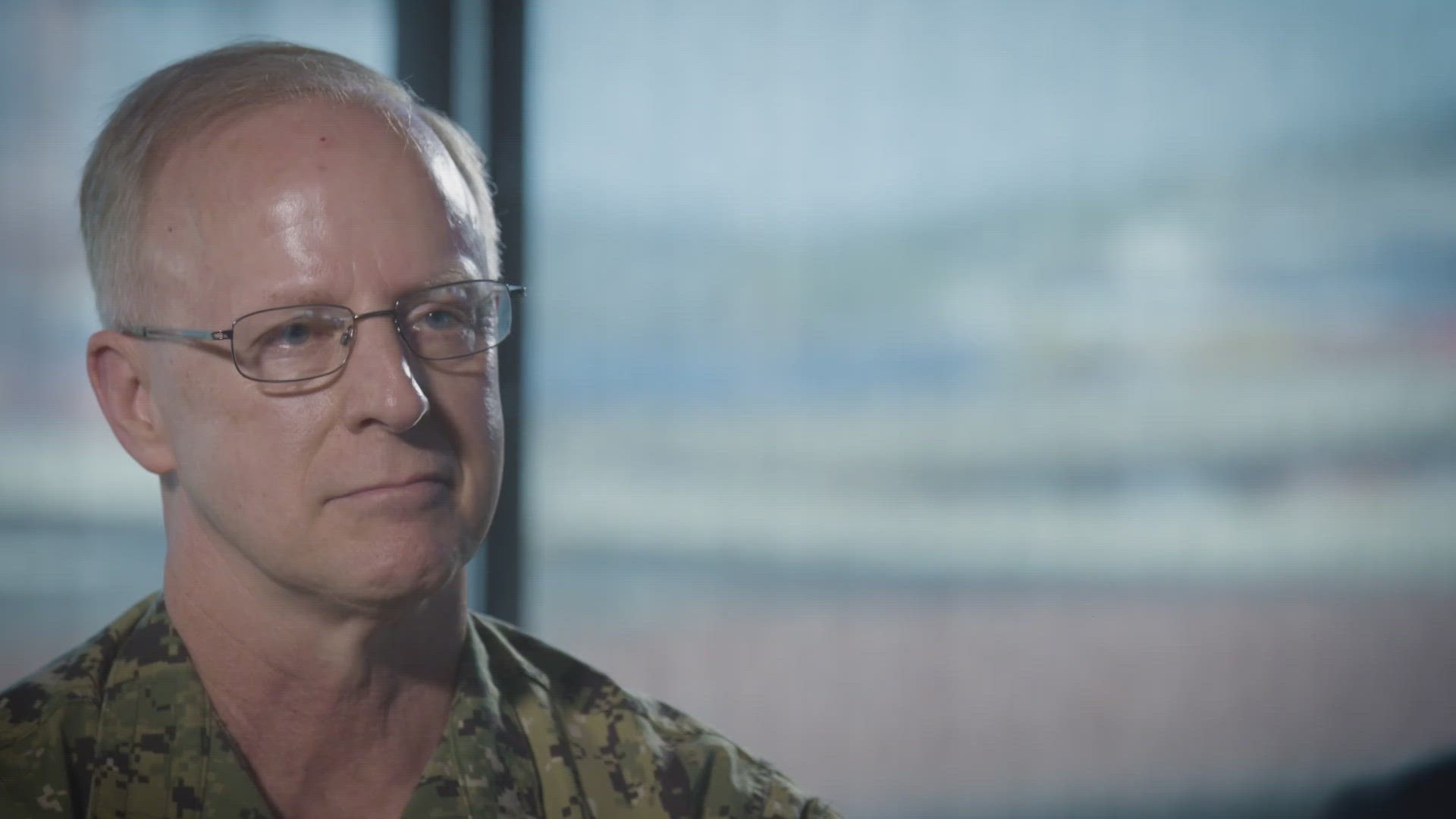

High Ranking Admirals Fall From Grace Corruption Charges And Conviction

May 20, 2025

High Ranking Admirals Fall From Grace Corruption Charges And Conviction

May 20, 2025 -

Four Star Admirals Corruption Conviction A Detailed Analysis

May 20, 2025

Four Star Admirals Corruption Conviction A Detailed Analysis

May 20, 2025 -

Retired Four Star Admiral Convicted Corruption Scandal Details

May 20, 2025

Retired Four Star Admiral Convicted Corruption Scandal Details

May 20, 2025 -

Corruption In The Us Navy The Case Of The Convicted Four Star Admiral

May 20, 2025

Corruption In The Us Navy The Case Of The Convicted Four Star Admiral

May 20, 2025 -

High Ranking Admiral Sentenced Details Of The Corruption Case

May 20, 2025

High Ranking Admiral Sentenced Details Of The Corruption Case

May 20, 2025