How U.S. Companies Are Adapting To Tariff Uncertainty Through Cost Cuts

Table of Contents

Restructuring Supply Chains to Minimize Tariff Impact

Dealing with tariff uncertainty requires a fundamental shift in how companies manage their supply chains. Two primary strategies are gaining traction: near-shoring and reshoring, and diversifying sourcing.

Nearshoring and Reshoring

Nearshoring and reshoring involve bringing manufacturing and production closer to the U.S. to reduce reliance on regions subject to fluctuating tariffs. This strategy aims to improve supply chain Tariff Mitigation Strategies and enhance overall resilience.

- Examples: Several apparel companies have shifted production from Asia to Mexico or Central America, while some electronics manufacturers are bringing assembly back to the U.S.

- Cost-Benefit Analysis: While relocation involves initial investment in infrastructure and potentially higher labor costs, the long-term benefits of reduced tariff exposure and faster delivery times often outweigh the initial expenses.

- Challenges: Reshoring faces obstacles like higher labor costs in the U.S. compared to some overseas locations and potential limitations in available skilled labor and infrastructure. Careful planning and potential government incentives are crucial for successful reshoring initiatives. Nearshoring offers a balance, utilizing lower-cost neighboring countries while shortening supply chains.

Diversifying Sourcing

Reducing dependence on single-source suppliers vulnerable to tariffs is crucial. Supply Chain Diversification is key to building a more resilient and flexible supply chain.

- Benefits: Diversification provides a buffer against tariff hikes and disruptions from a single source. It also strengthens negotiating power with suppliers.

- Challenges: Managing multiple suppliers adds complexity to logistics, requires robust communication systems, and may increase overall administrative costs. Careful supplier selection and contract negotiation are essential for successful Global Sourcing. This method is vital for Tariff Risk Management. Utilizing multiple sourcing options provides flexibility against unexpected tariff increases and supplier disruptions.

Optimizing Operational Efficiency for Cost Reduction

Beyond supply chain restructuring, internal operational efficiencies are vital for mitigating tariff impacts. Two crucial areas are lean manufacturing and technology adoption.

Lean Manufacturing and Process Improvement

Implementing lean principles eliminates waste and streamlines operations. This contributes to substantial cost savings.

- Lean Techniques: Techniques such as Kaizen (continuous improvement) and Six Sigma (data-driven process improvement) identify and eliminate inefficiencies in production and supply chains.

- Quantifiable Results: Companies implementing lean manufacturing often see significant reductions in production time, inventory costs, and waste, directly impacting their bottom line.

- Challenges: Successfully implementing lean manufacturing requires strong employee buy-in, comprehensive training, and a commitment to continuous improvement. This is an essential element of Cost-Cutting Strategies.

Technology Adoption and Automation

Technology plays a crucial role in automating processes, reducing labor costs, and enhancing efficiency.

- Automation Technologies: Robotics, artificial intelligence (AI), and other advanced technologies offer opportunities to automate repetitive tasks, improve accuracy, and increase overall productivity. Automation and Robotics are key components of modern cost reduction.

- Return on Investment: While initial investment can be substantial, the long-term return on investment from automation is often significant, leading to sustainable cost reductions.

- Job Displacement Concerns: Automation can raise concerns about job displacement. Companies must address these concerns proactively through retraining programs and a focus on reskilling the workforce. This is a crucial aspect of successfully utilizing Technological Advancements and Cost Reduction Technologies.

Negotiating with Suppliers and Managing Pricing

Effective negotiation and cost analysis are integral to managing expenses.

Strategic Partnerships

Building strong, long-term relationships with key suppliers offers significant advantages.

- Benefits: Strong partnerships lead to better pricing, preferential treatment during shortages, and enhanced collaboration on cost-reduction initiatives. This is a key element of Supplier Relationship Management.

- Collaborative Strategies: Joint ventures, shared risk-sharing arrangements, and collaborative design efforts can identify cost-saving opportunities. This strategy allows companies to enhance Cost Reduction Through Collaboration.

- Challenges: Securing reliable and trustworthy suppliers requires diligent due diligence and ongoing relationship management.

Price Transparency and Cost Analysis

Detailed cost analysis and price transparency are crucial for identifying areas for savings.

- Techniques for Cost Analysis: Activity-based costing, value engineering, and other analytical tools help identify areas of high cost and potential cost reduction.

- Data-Driven Decision Making: Using data to inform pricing decisions ensures efficient allocation of resources and helps to eliminate unnecessary expenses.

- Challenges: Obtaining accurate cost data from suppliers requires robust communication and potentially requires significant effort to analyze complex data. This contributes to the overall goal of Efficient Cost Management.

Conclusion

U.S. companies are employing a multifaceted approach to combat tariff uncertainty through cost-cutting. Restructuring supply chains (through Nearshoring, Reshoring, and Supply Chain Diversification), optimizing operational efficiency (with Lean Manufacturing and Automation), and strategically managing supplier relationships (through Strategic Partnerships and Cost Analysis) are all crucial strategies. Proactive adaptation is key to navigating these challenges. By implementing these cost-cutting strategies and proactively adapting to tariff uncertainty, U.S. companies can strengthen their resilience and maintain competitiveness in the global market. Don't wait for tariffs to impact your bottom line – begin implementing your own Tariff Mitigation plan today! Develop effective cost-cutting strategies and start navigating tariff challenges now.

Featured Posts

-

European Central Bank Highlights Fiscal Supports Role In Inflation

Apr 29, 2025

European Central Bank Highlights Fiscal Supports Role In Inflation

Apr 29, 2025 -

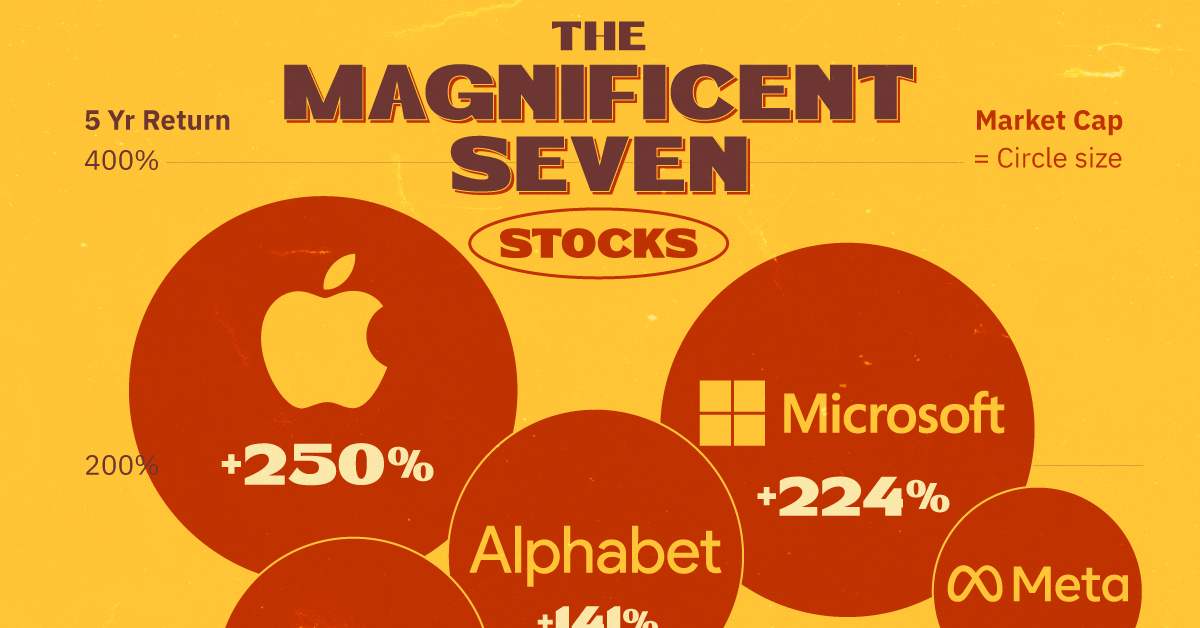

Magnificent Seven Stocks 2 5 Trillion In Lost Market Value This Year

Apr 29, 2025

Magnificent Seven Stocks 2 5 Trillion In Lost Market Value This Year

Apr 29, 2025 -

Murder Conviction For Teen Involved In Fatal Rock Throwing

Apr 29, 2025

Murder Conviction For Teen Involved In Fatal Rock Throwing

Apr 29, 2025 -

Exclusive Huawei Develops Advanced Ai Chip To Rival Nvidia

Apr 29, 2025

Exclusive Huawei Develops Advanced Ai Chip To Rival Nvidia

Apr 29, 2025 -

Unveiling The Ccp United Fronts Activities In Minnesota

Apr 29, 2025

Unveiling The Ccp United Fronts Activities In Minnesota

Apr 29, 2025

Latest Posts

-

Nintendos Action Ryujinx Emulator Development Ceases

Apr 29, 2025

Nintendos Action Ryujinx Emulator Development Ceases

Apr 29, 2025 -

100 Immigrants Detained In Underground Nightclub Raid Exclusive Video Footage

Apr 29, 2025

100 Immigrants Detained In Underground Nightclub Raid Exclusive Video Footage

Apr 29, 2025 -

One Plus 13 R Review A Practical Assessment Against The Pixel 9a

Apr 29, 2025

One Plus 13 R Review A Practical Assessment Against The Pixel 9a

Apr 29, 2025 -

Review One Plus 13 R Performance And Value Compared To The Pixel 9a

Apr 29, 2025

Review One Plus 13 R Performance And Value Compared To The Pixel 9a

Apr 29, 2025 -

Over 100 Immigrants Detained In Underground Nightclub Raid Video Evidence

Apr 29, 2025

Over 100 Immigrants Detained In Underground Nightclub Raid Video Evidence

Apr 29, 2025