The Complexities Of All-American Manufacturing

Table of Contents

The Rising Costs of Domestic Production

The pursuit of All-American Manufacturing is commendable, yet it faces significant headwinds stemming from the inherently higher costs of production within the United States.

Labor Costs

- Higher Wages: US wages are considerably higher than in many other manufacturing hubs, such as China, Vietnam, and Mexico. This directly impacts the overall cost of production. While a skilled American workforce offers unmatched quality and productivity, the price differential remains a significant challenge for domestic manufacturers competing on price.

- Automation as a Solution: To offset higher labor costs, many All-American manufacturers are investing heavily in automation and robotics. This can increase upfront costs but ultimately lead to increased efficiency and reduced reliance on manual labor.

- Comparison: A simple comparison reveals the stark difference: Producing a single garment in the US can cost several times more than producing the same garment in Bangladesh due to the substantial difference in labor costs.

Raw Material Sourcing

- Transportation Costs: Sourcing raw materials domestically often entails higher transportation costs compared to importing materials from countries with closer proximity to manufacturing facilities. This adds to the overall cost of All-American Manufacturing.

- Tariffs and Trade Policies: Government tariffs and trade policies significantly impact the availability and cost of raw materials. Fluctuations in these policies create uncertainty for manufacturers planning long-term production strategies.

- Environmental Impact: While importing materials might seem cheaper initially, the environmental costs associated with long-distance transportation should be considered. Prioritizing sustainable and domestically sourced materials, while initially more expensive, contributes to a smaller carbon footprint and aligns with environmentally conscious consumer preferences, ultimately boosting the image of All-American Manufacturing.

Regulatory Compliance

- Stringent Regulations: The US boasts stringent environmental regulations and safety standards, ensuring high-quality and environmentally responsible production. However, meeting these standards comes with considerable costs.

- Compliance Costs: The costs associated with adhering to these regulations, including environmental impact assessments, safety audits, and waste management, are substantial and contribute to the higher overall cost of All-American Manufacturing.

- Tax Incentives: Fortunately, the government offers various tax incentives and grants to companies that adopt environmentally friendly manufacturing practices. These incentives help alleviate some of the financial burden associated with compliance.

Competition from Global Markets

The globalized nature of manufacturing presents significant challenges for All-American Manufacturing.

Import Competition

- Lower Prices: Imports often undercut domestically produced goods due to lower labor costs, less stringent regulations, and potentially lower transportation costs. This makes it difficult for All-American manufacturers to compete directly on price.

- Impact on American Jobs: The influx of cheaper imports can lead to job losses in the US manufacturing sector, negatively impacting the economy and individual livelihoods.

- Competitive Strategies: To counter import competition, All-American manufacturers often focus on niche markets, producing specialized or high-quality goods that command premium prices and are less susceptible to direct competition from low-cost imports.

Offshoring Trends

- Cost Savings: Many companies choose to offshore manufacturing to reduce production costs, particularly labor costs. This trend poses a significant threat to All-American Manufacturing.

- Supply Chain Disruptions: Offshoring can lead to vulnerabilities in the supply chain. Geopolitical instability, natural disasters, or pandemics in the country where manufacturing is located can disrupt production and cause delays.

- Reshoring Initiatives: Recognizing the risks of offshoring, many companies are now embracing reshoring – bringing manufacturing back to the US. This trend offers hope for the future of All-American Manufacturing, but significant investment is needed.

Supporting and Strengthening All-American Manufacturing

Strengthening All-American Manufacturing requires a multifaceted approach involving government support, technological advancements, and consumer engagement.

Government Policies and Incentives

- Tax Breaks and Subsidies: Government tax breaks, subsidies, and other financial incentives play a crucial role in supporting domestic manufacturers and making All-American Manufacturing more competitive.

- Effectiveness of Programs: The effectiveness of these programs is crucial and needs continuous evaluation and adjustment to ensure maximum impact. Streamlining bureaucratic processes and reducing red tape are key to making these programs truly effective.

- Trade Policies: Strategic trade policies are essential to level the playing field and protect domestic manufacturers from unfair competition.

Investing in Innovation and Technology

- Automation and Robotics: Investment in automation, robotics, and advanced manufacturing technologies is vital for increasing efficiency, reducing labor costs, and improving productivity.

- Worker Training: Investing in worker training and skills development is crucial to ensure the American workforce has the skills needed to operate advanced manufacturing technologies and maintain a competitive edge.

- R&D Funding: Government funding for research and development in manufacturing technologies is crucial for fostering innovation and keeping American manufacturers at the forefront of technological advancements.

Consumer Demand and Brand Loyalty

- Buy American Movement: The "Buy American" movement encourages consumers to prioritize purchasing American-made products, supporting domestic manufacturers and jobs.

- Brand Loyalty: Building strong brands that emphasize quality, durability, and the benefits of American-made goods can cultivate consumer loyalty and drive demand for All-American products.

- Marketing Strategies: Effective marketing strategies that highlight the unique value proposition of All-American goods – including quality, craftsmanship, and commitment to ethical labor practices – are essential for boosting consumer demand.

The Future of All-American Manufacturing

The challenges facing All-American Manufacturing are considerable, yet the sector's resilience and potential for growth remain strong. Addressing the rising costs of domestic production, effectively competing with global markets, and fostering a supportive environment through government policies, technological innovation, and consumer engagement are crucial for ensuring the future success of this vital sector. Supporting domestic manufacturing is not only essential for economic growth but also for national security and ensuring the long-term prosperity of the United States. Learn more about how you can support the growth of All-American Manufacturing and contribute to a stronger American economy by researching organizations dedicated to promoting American-made products and advocating for policies that support domestic manufacturing.

Featured Posts

-

Wichita Black Hawk Helicopter Accident Pilots Actions Under Scrutiny

Apr 29, 2025

Wichita Black Hawk Helicopter Accident Pilots Actions Under Scrutiny

Apr 29, 2025 -

Ohio Doctors Parole Hearing Sons Struggle 36 Years After Wifes Murder

Apr 29, 2025

Ohio Doctors Parole Hearing Sons Struggle 36 Years After Wifes Murder

Apr 29, 2025 -

Snow Fox Weather Update Service Impacts For Tuesday February 11th

Apr 29, 2025

Snow Fox Weather Update Service Impacts For Tuesday February 11th

Apr 29, 2025 -

What We Learned About Treasuries On April 8th

Apr 29, 2025

What We Learned About Treasuries On April 8th

Apr 29, 2025 -

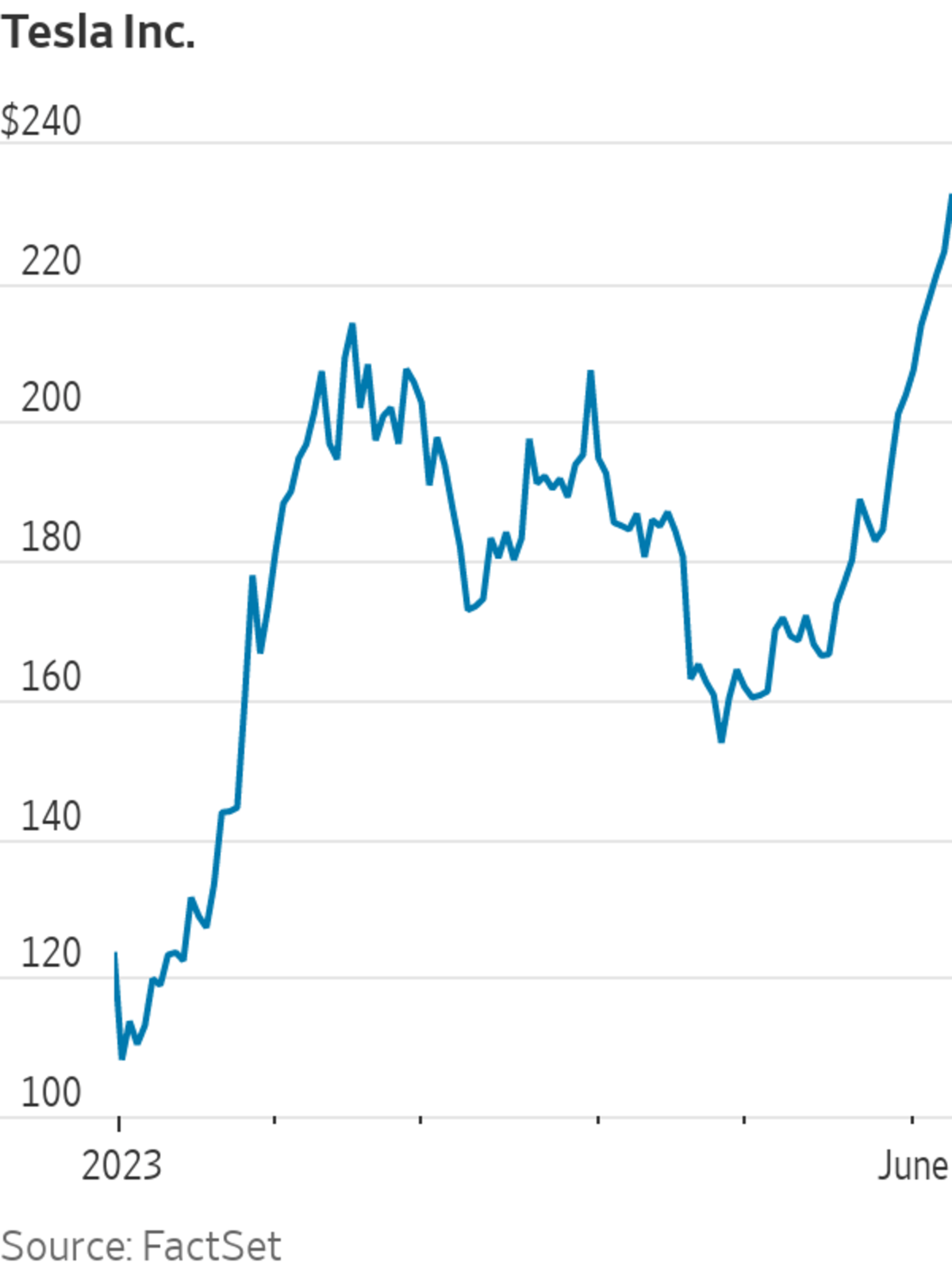

Tesla And Tech Drive Us Stock Market Surge

Apr 29, 2025

Tesla And Tech Drive Us Stock Market Surge

Apr 29, 2025

Latest Posts

-

Capital Summertime Ball 2025 Wembley Stadium Tickets And Event Details

Apr 29, 2025

Capital Summertime Ball 2025 Wembley Stadium Tickets And Event Details

Apr 29, 2025 -

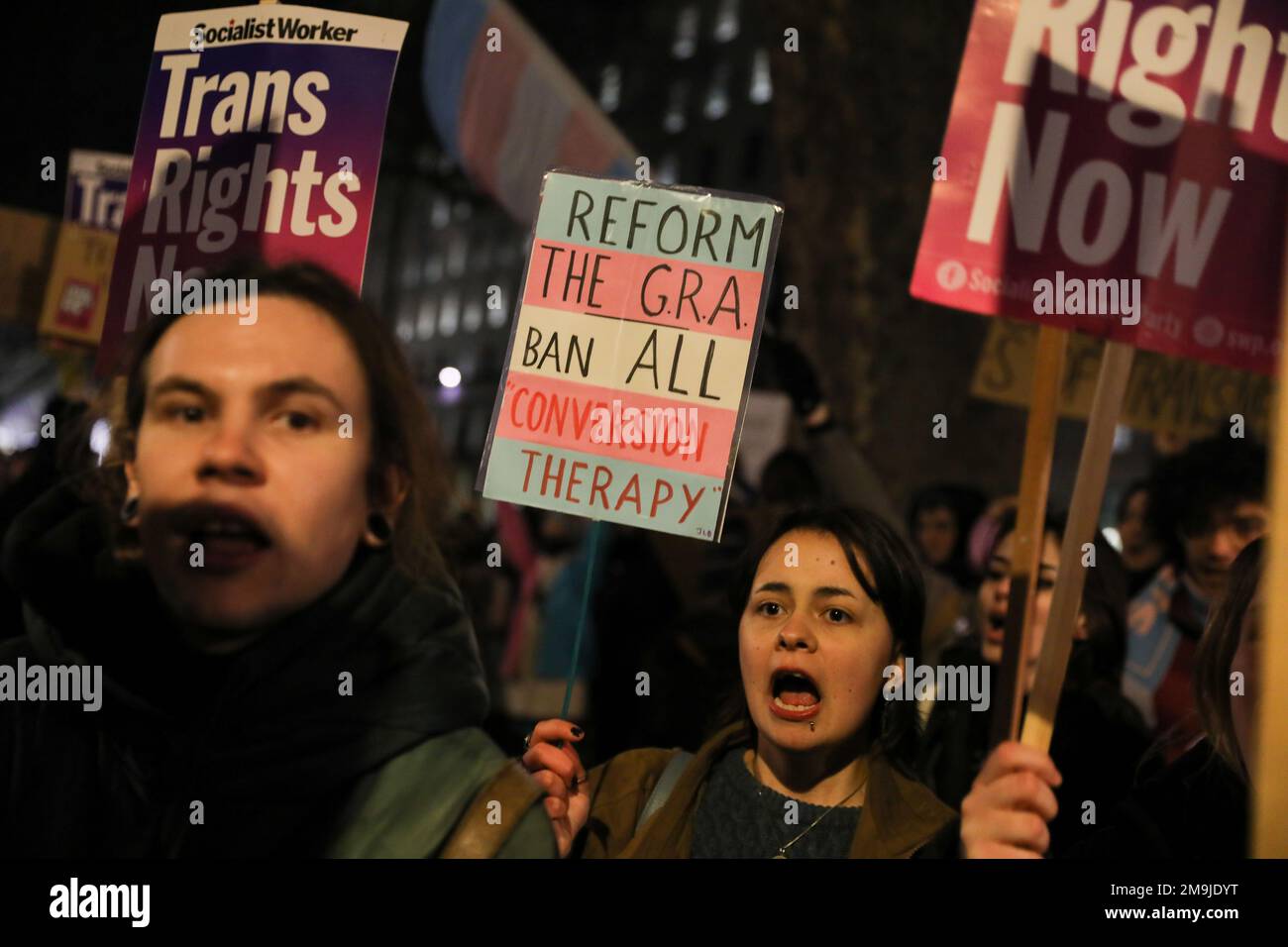

Twenty Thousand Strong Trans Rights Protest Demonstrates Growing Support

Apr 29, 2025

Twenty Thousand Strong Trans Rights Protest Demonstrates Growing Support

Apr 29, 2025 -

20 000 March For Trans Rights A Powerful Display Of Solidarity

Apr 29, 2025

20 000 March For Trans Rights A Powerful Display Of Solidarity

Apr 29, 2025 -

Capital Summertime Ball 2025 Your Guide To Wembley Stadium

Apr 29, 2025

Capital Summertime Ball 2025 Your Guide To Wembley Stadium

Apr 29, 2025 -

Addressing Misogyny Mhairi Blacks Critique Of Womens And Girls Protection

Apr 29, 2025

Addressing Misogyny Mhairi Blacks Critique Of Womens And Girls Protection

Apr 29, 2025