Cost-Cutting Measures Surge As U.S. Companies Face Tariff Challenges

Table of Contents

Supply Chain Optimization and Restructuring

Navigating the complexities of global sourcing amidst fluctuating tariffs requires a strategic overhaul of supply chain management. Companies are actively exploring new sourcing strategies to mitigate the increased import costs. This involves carefully analyzing the total cost of ownership for each component and supplier, factoring in tariffs, transportation, and other related expenses.

-

Shifting sourcing strategies: Nearshoring and reshoring, relocating production closer to the U.S. market, are gaining significant traction. This reduces reliance on high-tariff countries and minimizes transportation costs and lead times. Companies are also exploring diversifying their sourcing base, reducing dependence on single suppliers vulnerable to price volatility or geopolitical instability.

-

Negotiating better terms: Strengthening supplier relationships is paramount. Companies are actively negotiating better terms with existing suppliers, seeking price reductions or more favorable payment terms to offset tariff increases. This requires a collaborative approach, building strong partnerships based on mutual benefit.

-

Optimizing logistics and transportation: Streamlining logistics networks through advanced route optimization software and exploring alternative transportation modes can significantly reduce shipping costs. Improved inventory management techniques, including just-in-time inventory systems, can further minimize warehousing expenses.

-

Diversifying Suppliers: Reducing reliance on a single supplier is critical. Diversifying the supplier base across multiple countries and regions helps mitigate risks associated with tariffs, political instability, and natural disasters. This proactive approach bolsters supply chain resilience and minimizes disruptions.

Automation and Technological Upgrades

Embracing automation and technological advancements offers a powerful pathway towards significant cost reductions and increased efficiency. The integration of innovative technologies not only reduces labor costs but also enhances productivity and quality.

-

Investing in automation: Robotics and automated systems are being increasingly deployed in manufacturing and warehousing operations, leading to improved output and reduced labor expenses. Automation also minimizes human error, reducing waste and improving product quality.

-

AI-powered solutions: Artificial intelligence (AI) offers significant potential for process optimization and cost reduction. AI-driven analytics can identify areas for improvement, optimize resource allocation, and predict potential problems before they occur.

-

Technology upgrades: Upgrading existing technology, including machinery and software, can improve efficiency and reduce waste. This includes adopting cloud-based solutions for data management, which offers significant cost advantages over on-premise infrastructure.

Operational Efficiency and Lean Manufacturing

Implementing lean manufacturing principles and adopting Six Sigma methodologies are pivotal in achieving substantial cost optimization and maximizing operational efficiency. These strategies focus on eliminating waste and streamlining operations.

-

Lean Manufacturing Principles: Focusing on waste reduction – reducing excess inventory, unnecessary movement, defects, and delays – improves overall efficiency. This streamlined approach minimizes production costs while maximizing output.

-

Process Improvement: Identifying and eliminating bottlenecks in production processes improves workflow, reducing lead times and operational costs. Continuous improvement initiatives, frequently using data-driven approaches, are key for maintaining efficiency.

-

Six Sigma Methodologies: The Six Sigma approach emphasizes reducing variation and defects in processes, leading to reduced waste and rework. This rigorous methodology ensures consistency and quality, directly impacting overall costs.

-

Quality Control: Implementing stringent quality control measures throughout the production process minimizes defects, reducing waste and the costs associated with rework or product recalls.

Workforce Management and Employee Costs

Managing workforce costs effectively requires a multifaceted approach that prioritizes employee retention while implementing strategic cost-saving measures. However, it's crucial to approach workforce reductions with caution and sensitivity.

-

Hiring freezes and reduced turnover: Implementing hiring freezes for non-essential positions and focusing on reducing employee turnover through improved employee engagement strategies can significantly reduce payroll costs.

-

Compensation and benefits review: Analyzing compensation and benefits packages to ensure competitiveness while identifying potential areas for cost savings is essential. This may involve exploring alternatives like flexible work arrangements or performance-based incentives.

-

Flexible work arrangements: Offering flexible work arrangements, such as remote work options or compressed workweeks, can reduce overhead costs associated with office space and utilities.

-

Investing in training: Investing in employee training and development improves productivity and reduces errors, potentially leading to long-term cost savings.

-

Workforce reduction (last resort): In extreme cases, workforce reductions may be unavoidable. However, this should be approached with careful consideration, sensitivity, and legal compliance.

Marketing and Sales Strategies

Optimizing marketing and sales strategies is crucial for maximizing ROI and minimizing marketing expenses. Businesses need to adapt their approaches to achieve cost-effectiveness without compromising reach or effectiveness.

-

Marketing campaign optimization: Analyzing marketing campaign data to identify high-performing channels and allocate resources accordingly is key. This data-driven approach improves ROI and minimizes wasted spending.

-

Cost-effective digital marketing: Investing in cost-effective digital marketing strategies, such as SEO, social media marketing, and email marketing, can expand reach at a fraction of the cost of traditional advertising.

-

Customer retention: Improving customer retention rates reduces the need for costly customer acquisition campaigns. Loyalty programs and excellent customer service contribute significantly to retention.

-

Targeted lead generation: Focusing on generating high-quality leads through targeted campaigns ensures efficient resource allocation and maximizes conversion rates.

Conclusion

The challenges presented by tariffs are forcing U.S. companies to adopt aggressive cost-cutting measures across all aspects of their operations. From supply chain restructuring to technological upgrades and workforce management, businesses are exploring every avenue to maintain profitability and competitiveness in this challenging global trade environment. Understanding and implementing effective cost-cutting measures is crucial for U.S. companies navigating the complexities of the current economic landscape. Don't let tariffs cripple your business. Start exploring strategies for cost optimization today to safeguard your future. Learn more about navigating the impact of tariffs on your business by [link to relevant resource/service].

Featured Posts

-

British Paralympian Missing In Las Vegas Search Intensifies After Over A Week

Apr 29, 2025

British Paralympian Missing In Las Vegas Search Intensifies After Over A Week

Apr 29, 2025 -

Analyzing The Effectiveness Of Minnesotas Film Tax Credit Program

Apr 29, 2025

Analyzing The Effectiveness Of Minnesotas Film Tax Credit Program

Apr 29, 2025 -

Exploring The Cognitive Capacity Of Ai Beyond The Hype

Apr 29, 2025

Exploring The Cognitive Capacity Of Ai Beyond The Hype

Apr 29, 2025 -

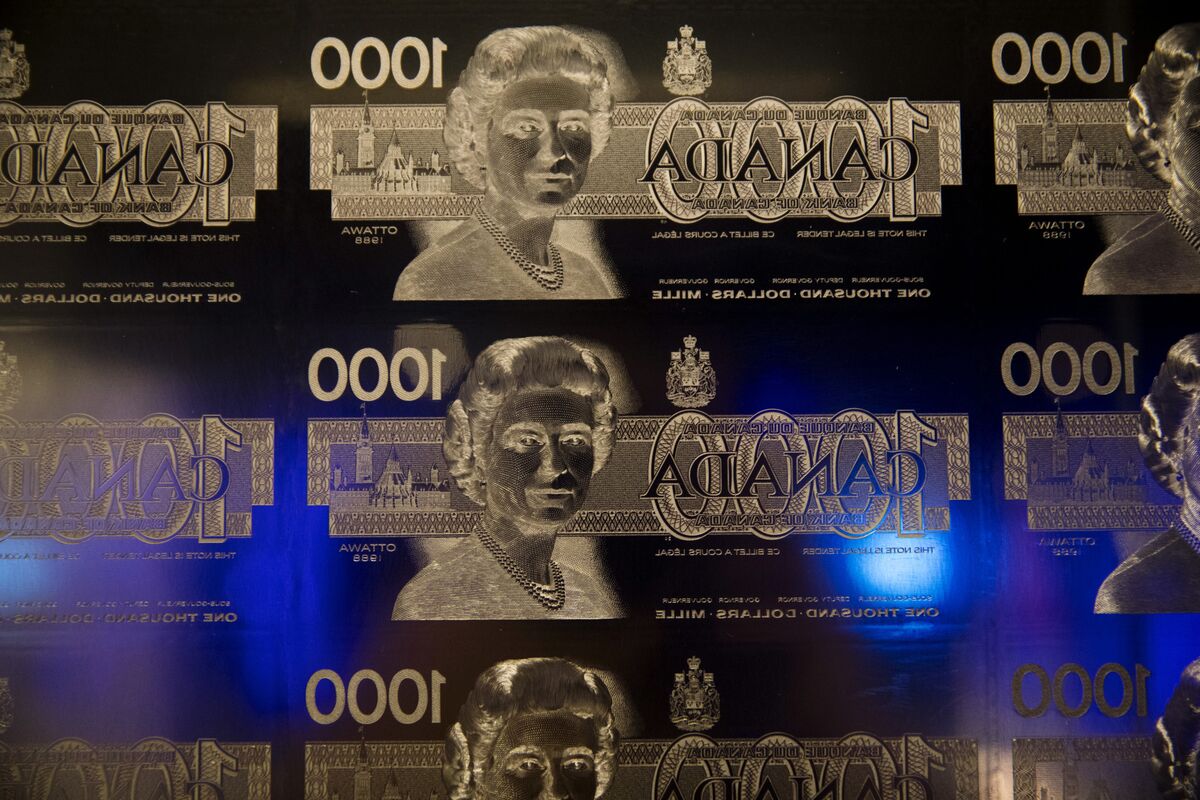

Rosenberg Accuses Bank Of Canada Of Monetary Policy Mistakes

Apr 29, 2025

Rosenberg Accuses Bank Of Canada Of Monetary Policy Mistakes

Apr 29, 2025 -

Why Kentucky Storm Damage Assessments Are Delayed

Apr 29, 2025

Why Kentucky Storm Damage Assessments Are Delayed

Apr 29, 2025

Latest Posts

-

Regionalliga Mitte Das Neue Trainerteam Des Dsv Leoben

Apr 29, 2025

Regionalliga Mitte Das Neue Trainerteam Des Dsv Leoben

Apr 29, 2025 -

Jancker Wird Neuer Austria Klagenfurt Coach

Apr 29, 2025

Jancker Wird Neuer Austria Klagenfurt Coach

Apr 29, 2025 -

Austria Klagenfurt Jancker Uebernimmt Traineramt

Apr 29, 2025

Austria Klagenfurt Jancker Uebernimmt Traineramt

Apr 29, 2025 -

Janckers Zukunft Nach Leoben Wohin Fuehrt Der Weg

Apr 29, 2025

Janckers Zukunft Nach Leoben Wohin Fuehrt Der Weg

Apr 29, 2025 -

Nyr Porsche Macan Allt Um Fyrstu Rafutgafuna

Apr 29, 2025

Nyr Porsche Macan Allt Um Fyrstu Rafutgafuna

Apr 29, 2025